By Joe Gresh

Monsoon season has streamed into New Mexico’s upper atmosphere, hampering my concrete construction projects so I took the opportunity to settle some old scores with Godzilla, my 1971 Yamaha RT1-B Enduro. I’m getting the bike ready for a west coast trip and there were some annoying little faults I wanted to do up right before riding the California coast.

Godzilla has grown over the years. I’ve put a taller 21” front wheel on the bike and longer rear shocks. As a result the bike leans way over on the original-length kickstand. Parked in the shed I use a chunk of 2×4 to make the Yamaha sit more vertical but I’m not about to carry lumber all the way to California.

I measured the length needed, about 1-1/2-inch, and cut some tube off an old handlebar I keep around for just this purpose. I’ve been altering a lot of kickstands lately. I don’t know why I have to keep messing with kickstands but there it is. I used a piece of tube from an old floodlight frame to make a centering piece so that the three sections stay straight.

The tube from the floodlight was slotted and press fit into the extension piece.

Then all the pieces were assembled and welded together. After welding I touched up the stand with a bit of spot putty and gloss black paint.

The angle worked out great. Unfortunately the longer stand now hit the lower chain guard bolt when in the up position.

To solve this problem I added a blob of weld to the kickstand stop; this increased the clearance between the longer stand and the chain guard.

There are two distinct areas of wear. The first is the hub boss that the sprocket carrier rides on. The second problem is the distance between the sprocket carrier retaining circlip and the carrier had become quite wide, meaning the clip didn’t hold the carrier tight to the hub. This allowed the carrier to wander in and out, causing even more wear on the hub boss.

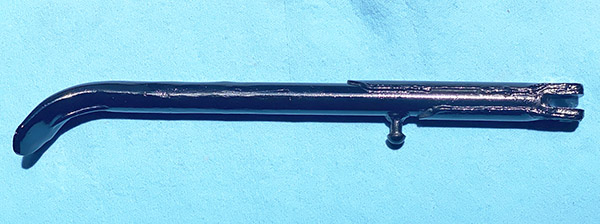

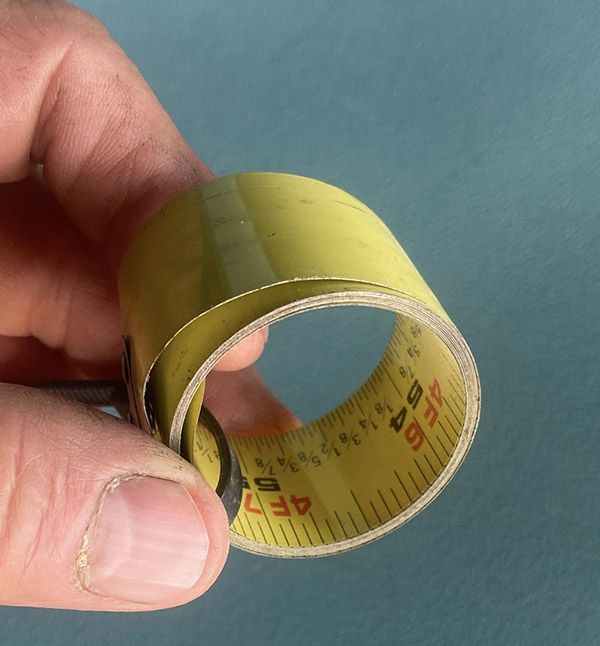

To fill the gap between the hub boss and carrier I used a section of well-greased, steel measuring tape as a shim. I wound the tape around the boss and held it into position with a bit of string. To determine the thickness needed I started long and trial fit the carrier. I kept decreasing the tape length until the carrier would just slip over the shim.

For the circlip gap I was lucky and found a piece of aluminum pipe that fit nearly perfectly and trimmed off a baloney slice to use as a shim.

By trial and error I fit and re-fit the shim. I used the South Bend lathe to reduce the thickness of the shim bit by bit until the clip would fit without any back and forth play. Now the sprocket carrier is snug to the hub but still has a bit of rotational movement between the hub’s rubber cushions.

Godzilla seems to be in pretty good shape right now. It’s running a bit rough but that’s probably due to the old gas in the tank. I’ll dilute the crap gas with fresh and take the bike out for a nice long ride. See you in California!

Never miss an ExNotes blog: