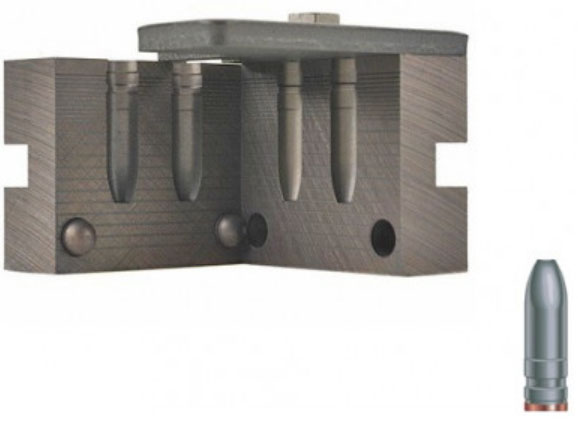

When I was younger, I made my own bullets by casting them out of molten lead. I cast bullets until I decided there wasn’t enough time to do everything I want to do. Shooting can be a full time hobby, reloading can be a full time hobby, and casting can be a full time hobby. There’s a little motorcycle riding and some writing thrown in there, too. Something had to give, so a few years ago I sold all my bullet casting gear.

I still enjoy reloading and shooting cast bullets, though, for a lot of reasons. Lighter recoil, cheaper bullets (usually), less barrel wear, and the big factor: It’s fun and it’s challenging. This fascination with cast bullets, for me, started when I ran with a bunch of gunsels in El Paso and one of the guys decided it would be fun if we had a cast bullet rifle bullseye competition. Being mostly engineers, we reckoned that big bore rifles would be the way to go, as the larger bullet diameters and weights would tend to make bullet weight differences and imperfections negligible. The first rifle I ever shot a cast bullet in was a .458 Win Mag. I was hooked after the first shot, mostly because there was far less recoil than shooting jacketed factory ammo and the experience was much more enjoyable. Then I fired four more shots and when I saw the 1-inch group at 100 yards (from a .458 Win Mag!) I was hooked. We all shot big bores in those days: .458s, .45 70s, .375 H&H Magnums, and such. Cast bullets in these big calibers can be amazingly accurate.

Anyway, I fell in love with cast bullets and I’ve been shooting them ever since, but these days I buy my cast bullets. I have a local source for cast bullets, and I have a few I like that I order online or pick up at my dealer (that’s Phillips Wholesale in Covina, California). I also poke around a bit on the Internet and a few weeks ago I found Gardner’s Cache, another commercial bullet casting operation. What had my attention immediately is that Jim Gardner’s prices are relatively low, he’s a veteran, and he had something I had not been able to find elsewhere at a decent price: 7mm cast rifle bullets. I wanted to try cast bullets in a couple of 7mm rifles (one being the Ruger No. 1 that you see at the top of this blog), so I ordered a box of 250. Then USPS lost the shipment. I filled out an online lost shipment report, the boys in blue located my bullets, and a few days later they arrived. The Gardner bullets look great.

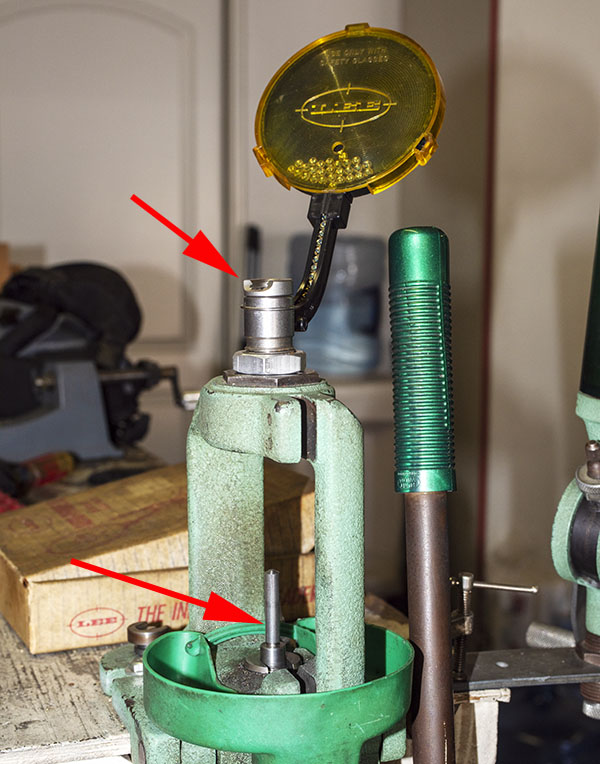

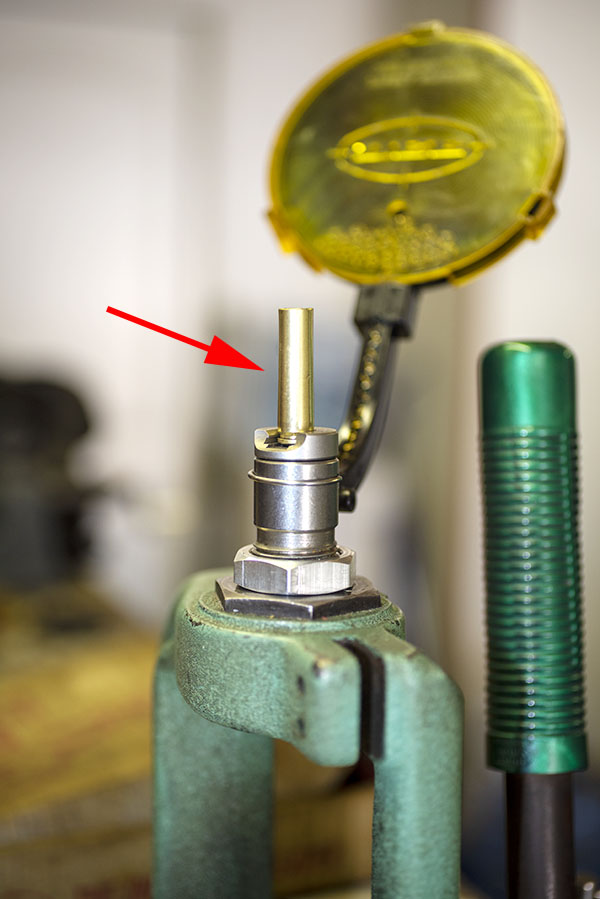

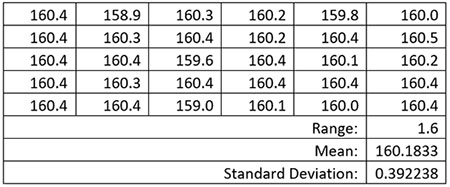

I could see that the casting quality was high, so just for grins I measured 30 projectiles to get a feel for the variability.

It was good. You ordinarily get a lot more variability with cast bullets then you do with jacketed bullets, but the Gardner bullets were more consistent than other cast bullets I’ve used. As I reviewed the data, it suddenly hit me that these were supposed to be 145-grain bullets. I could see from the bullets’ configuration that they matched the RCBS No. 82150 bullet mold, but what the mold maker tells you the bullet is supposed to weigh and what they actually weigh seldom line up. I had seen this before with other cast bullets.

I loaded several configurations with my new Gardner cast bullets in virgin Remington brass I had on the shelf, and the cartridges looked good.

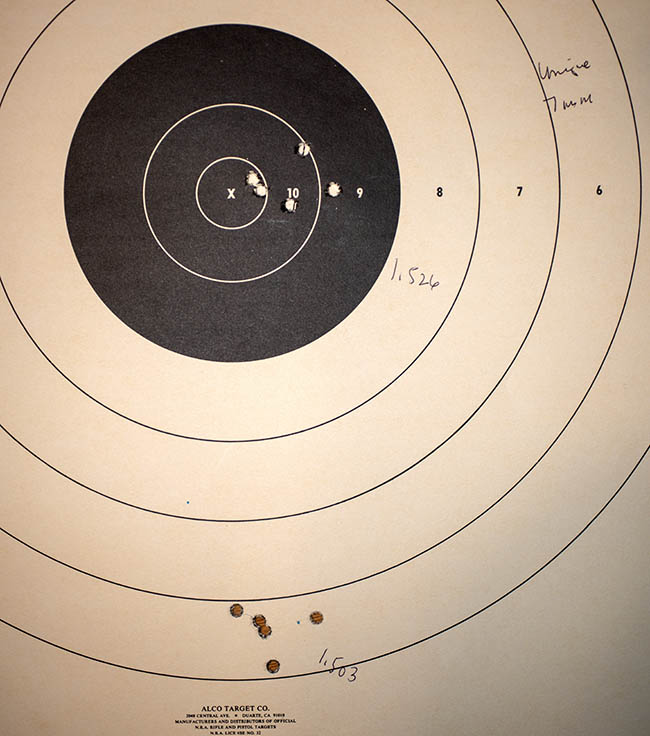

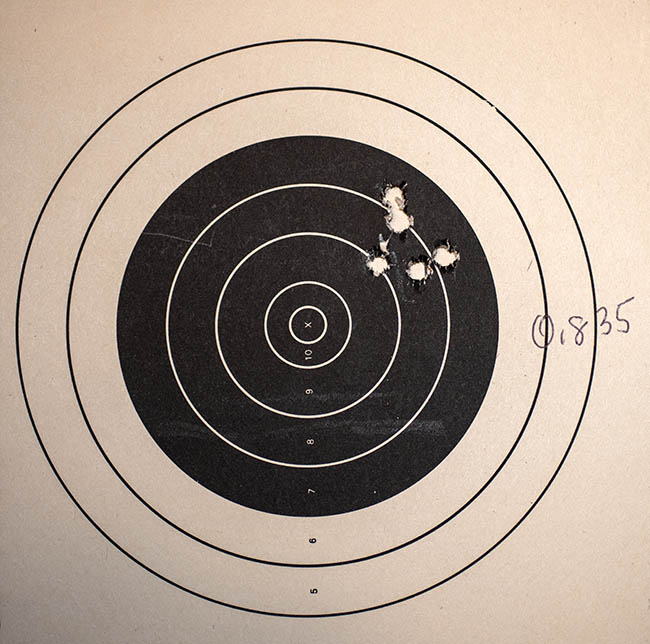

I went to the range the next day with the 7mm Remington Magnum Ruger No. 1 and my new cast bullet load, and after getting set up I fired the first load (with Unique propellant) at a single pistol target at 50 yards. The rifle had been zeroed for a factory equivalent jacketed load, and the results were very predictable. Whenever I’ve taken a centerfire rifle zeroed for factory ammo and shot cast bullets in it, the load is always about 10 inches low at 50 yards.

The required telescopic sight adjustment in going from jacketed to cast is something I know by heart: 80 clicks up. You can see the first five-shot group at 6:00 in the 5-ring on the above target. Windage looked about right, so I went 80 clicks up on the Ruger’s Weaver 3×9 scope. Each click is 1/4-inch at a hundred yards so that means a click is 1/8-inch at 50 yards, and I had to go up 10 inches. 10 inches is 80 clicks. I made that adjustment and oila, the second group was right where I wanted it. It was exactly the same as the amount of elevation I had to crank into my .30 06 Browning B78 when going from jacketed to cast bullets.

Then I moved over to the other targets I had set up at 50 yards. I’d like to tell you that all groups were tight, but hey, you do this to find out what works and what doesn’t. My best group of the day was with 18.0 grains of Trail Boss propellant, but it wasn’t as consistent as the Unique load was.

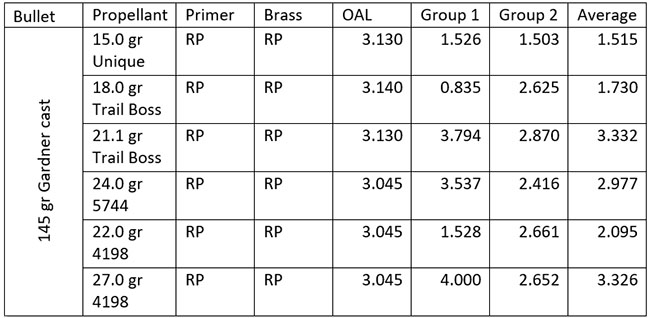

Here’s what I experienced with the first six loads I’ve tried with these bullets. Yep, there’s a lot of variability on some, but I’m encouraged.

I’ve already loaded more 7mm ammo with the Unique and Trail Boss loads, and I’m also going to try IMR 4227. I don’t think that 4227 will do as well as the first two loads, though. We’ll see. After that, I’m moving the targets out to 100 yards. That will be interesting, and when I do, you’ll see the results here on the ExNotes blog.

I already used about half of the 250 Gardner bullets that came in the first box. The results in my Ruger No. 1 made me a happy camper and I ordered another 1000 7mm rifle bullets a few days ago. If you want good cast bullets at a great price, you might take a look at Jim’s website.

More Tales of the Gun are waiting for you here!

Never miss an ExNotes blog!

Hit those pop up ads!