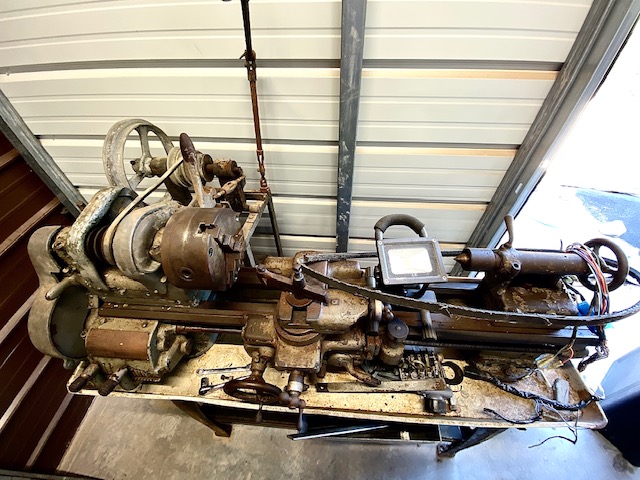

As much as I enjoy concrete work I need to take a break now and then. I ran out of mud for the back patio (164 bags, missed it by 10 bags!) so I decided to get my old South Bend 6’ lathe up and running.

My Pop bought the South Bend way back in the late 1960’s. I was just a kid but I remember riding in Pop’s Chevy ¾ ton, picking up the machine and unloading it at our house. It was and still is the heaviest thing I ever want to move. We were lucky in that the South Bend came with a crap load of attachments: a full set of collets, three steady rests, a 3-jaw and 4-jaw chuck and hundreds of tool bits were thrown in with the lathe.

Pops gave me the lathe 14 years ago. He said he was never going to use it again and he needed more room. I took the lathe down to The Florida Keys, where we lived at the time, and it went under water several times due to hurricanes. The motor was mounted lower on the lathe frame so it was lost to the elements. The rest of the lathe sat higher and was ok. All I did in The Keys was work so the South Bend sat for many years and I dragged it out to New Mexico in The Big Haul Ryder truck.

With the Covid, stay-at-home orders I decided now is the time to get the old machine running again. Back when we first got the lathe I asked my dad, “What does it do?” He told me “Everything”. He said, “You can make another lathe with a lathe!” Pops was a good machinist and he showed me the basics of operation. I was cutting threads on the South Bend within a few weeks.

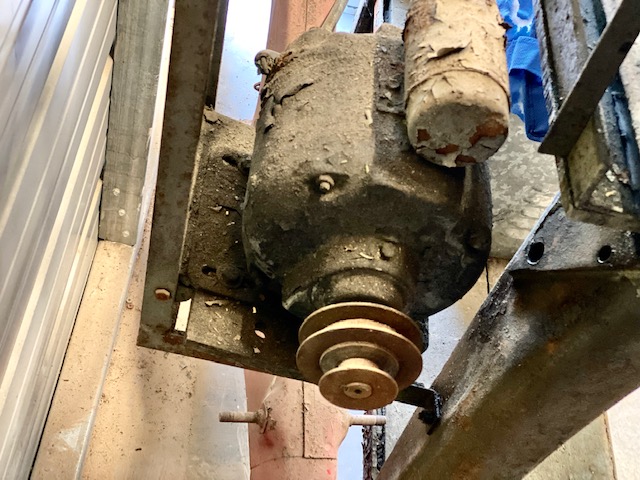

The South Bend came with a hokey, home-made motor/pulley setup that we were going to change 50 years ago but never got around to it. The pulley set up is ugly but it works and that’s probably why it stayed. This go-round I’m leaving it as is. The next guy can come up with a better system. Because with lathes there is always a next guy: they don’t wear out.

The old motor had a wider mounting bolt footprint and one hole of the 4 mounting holes was used for an adjuster bolt. I re-drilled the plate to suit the new motor and tapped the holes for 5/16” bolts.

For the adjusting bolt I used the existing motor mount holes but made a bar to go underneath. The new bar extends past the motor plate to line up with the adjuster bolt. It looks a little better than the previous setup. I need a few parts to finish the new motor installation so that will have to wait.

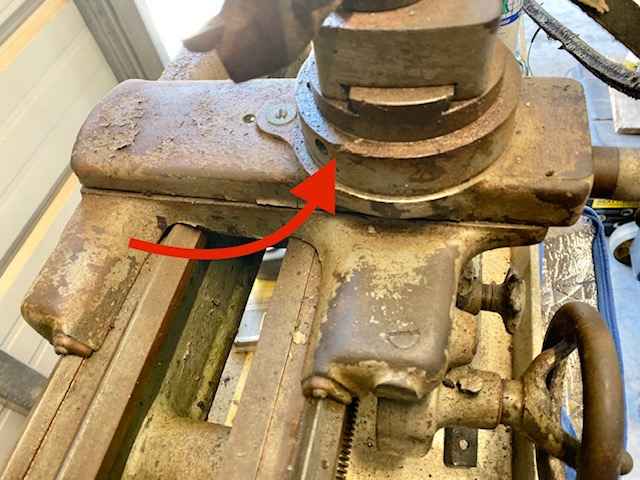

The South Bend is a 6” lathe but at some point in the past it was jacked up to an 8” lathe (swing over V-ways). The 1” spacer blocks look so well made they may be factory parts. I’m leaving them.

One of the nice things about this lathe is that it has not been abused. The thing is probably 70 years old and V-ways are smooth and unscarred from work falling out of the chuck and smacking into them. This means that a good machinist ran the thing.

That is, it was unscarred until I got my teen-age meat hooks on it. That gouge in the carriage was put there in the early 1970s by yours truly. I was cutting threads on a shaft, or maybe it was a taper, and the carriage self-fed into the chuck making a loud banging sound. I was confused; Pops was not happy and reamed me out. I never ran the carriage into the chuck again.

The forward/reverse switch is shot so I am replacing it with a toggle. Only because I have a 4-pole, double throw, center off toggle in stock. I’ve wanted to use that oddball switch forever. I’m also relocating the switch and wiring the motor 240-volt so that the 6000-watt solar-powered inverter can start the motor easier. With the old set up you had to reach over and between the spinning belts and pulleys to access the switch. It was sure a thing to keep you on your toes. Front mounting the switch will be mildly safer.

A lathe is one of the handiest machine tools you can own. The old ones are slightly clunkier to operate and I’ve forgotten most of what I knew about operating one. I’m sure YouTube is full of how-to lathe videos so I’ll brush up before I start making scrap metal.

While I wait for parts I’ll start cleaning the beast. Part 2 will cover the motor mounting, belts and wiring.

Never miss an ExNotes blog: Sign up here for new blog notifications:

Careful de-rusting the ways. You don’t want to make them un-true. I’d try a mild acid instead of abrasive.

I’m not using abrasives. Just oil and elbow grease.

I remember my dad’s lathe, first in our basement in CT. then in his garage/workshop in FL. I never got to use it but I watched/saw a lot of railings, pickets, table legs and bases, lamps and miscellaneous art pieces he made with it. I have to credit his lathe for getting me into design. Watching him and seeing the stuff he made from chunks of tree, I knew I’d never have skilz to match his so I went off in a different direction . I’m sure his lathe is still being used by someone who loves working wood as much as he did, because you’re right, old tooling like these never have to die ❤️

You are on a roll……major paving of the desert…… Kawasaki is now trip worthy ( no leaks for now)…… and now a lathe being resurrected for creative stuff ……. you the man!!

My Dad bought a South Bend lathe, just exactly like the one you have. There was a man in a close town, the had this in has attached garage. He was in the TV repair business, but in WWII he was a Navy machinists and did a little work on the side. Mostly starter and generator work. This was back in the late 50’s and early 60’s. When Max Patterson, retired, Dad bought it from him.

It has been in our/my shop ever since. I use it some for tractor restoration work.

The belt drive and speed change system is exactly the same as I have. My power switch still works just fine and the electric motor is still original.

My neighbor, 3 miles always acquired the same lathe, except his uncle bought it new for the farm. When he retired, he gave it to the High School shop. When the school closed, my neighbor, had a chance to buy his uncles lathe back. He now also has a end mill to add to his farm shop. He never realized how handy it is to have such equipment in his farm shop.

Thanks for your story, I will wait for the next installment.

You might not have intended this, but I am accepting your challenge: to get my 9″ South Bend lathe operationable again. It’s is a WWII vintage lathe with a War Production Board brass plaque and flat belt drive with 3×2 speeds vs. the 5×2 you have with the V belts. I haven’t used it in 25 years, and it suffered damage similar to your sea water situation: I was stripping the plating off some hardware and left an open container of muriatic acid in the shop overnight. The fumes corroded all of the bare metal in the shop including the ways of the lathe.

By the way, I don’t think you have a 6 foot lathe; rather, a 9 inch lathe that, with the spacer, is a 12 or 13 inch lathe.

I’ve always understood lathes to be measured by the swing over the bed and the distance between the headstock & the tail stock.

Some lathes have a removable section (gap bed) that allows you to swing larger work.

I could be all wrong. It’s been a long time since I ran the thing.

We had a second lathe. A big boy built in 1918 or some such year. It had the flat leather belts that clicked when the metal belt connector Slapped the flat pulley. It was all bronze bushings, no ball bearings. To change the spindle speed for threading rods you had to swap gears. There was a stack of gears for many different pitches.

The one I have now has the quick-change gearbox for spindle speed. No cog swapping!

I don’t remember what happened to the big lathe. It was just gone.