By Joe Berk

Here’s the latest accuracy rabbit hole I’ve gone down: Rim thickness as an accuracy factor for .22 Long Rifle ammo.

My friend Kevin told me about a hypothesis that holds you can get even cheap .22 ammo to shoot well if you sort by rim thickness. I researched this online, and like most things online, opinions are all over the map (Abraham Lincoln once famously said not everything you read on the internet is true). Kevin told me about this and suggested it might make for an interesting blog. I felt it was worth investigating, and I’d never considered .22 Long Rifle rim thickness as a variable until Kevin mentioned it.

Kevin had a specially fixtured dial indicator for measuring rim thickness (see the photo on top of this blog) and he lent it to me for this blog. I sorted a bunch of Federal Value Pack 36 grain .22 ammo. It’s cheap ammo. I’ll get to the results in a second.

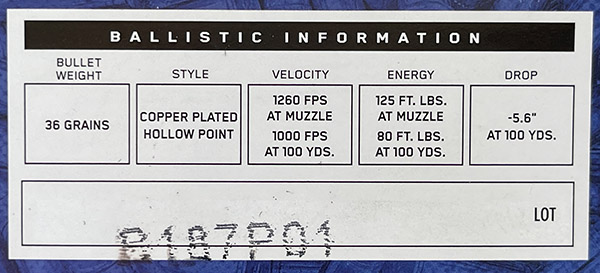

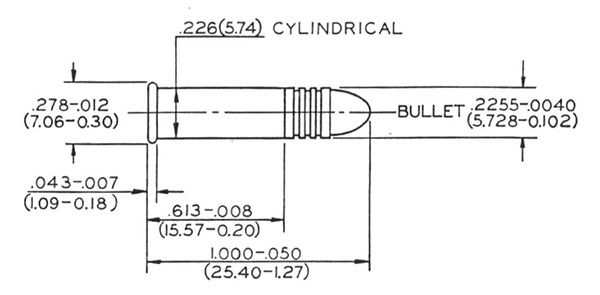

First, take a look at the SAAMI specs for sporting .22 Long Rifle ammo:

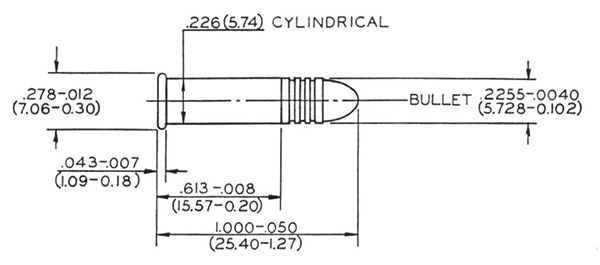

…and for match grade .22 LR ammo:

Yeah, I couldn’t see any difference between the two, either. You’d think match grade specs would be tighter, but they’re not. But check out that tolerance on rim thickness for both grades of .22 Long Rifle ammo…it varies from 0.036 to 0.043 inches. That seems like a huge tolerance to me.

If you read the SAAMI .22 Long Rifle chamber specs, the dimensioning there is the same for the chamber’s rim cavity on a sporting versus a match chamber. The chamber rim cavity can range from 0.043 to 0.051 inches. It would seem that a max thickness rim in a minimum length chamber would have line-to-line contact between the bolt face and the back of the cartridge. Any cartridge case that is less than 0.043 inches thick, or any chamber with the rim cavity longer than 0.043 inches, would allow clearance between the bolt face and the rear of the cartridge. Thicker rimmed cartridges would have minimal room to move around in the chamber, and should be more accurate.

The rim thickness versus accuracy hypothesis sounds like it could make sense. Differing rim thicknesses will influence headspace (.22 Long Rifle ammo headspaces on the rim), and that could influence accuracy. Also, as Kevin pointed out, rim thickness will affect firing pin strike on the cartridge case, so if the thicknesses are identical, the firing pin strike should be the same (and that should result in improved accuracy). It all sounds good, anyway.

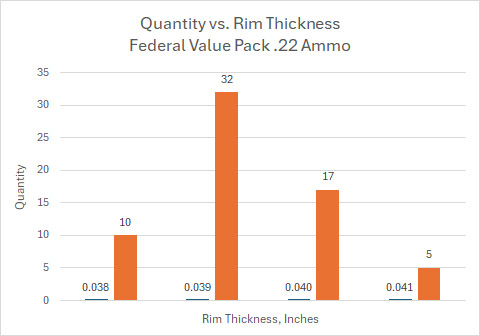

I used Kevin’s dial indicator and measured rim thickness until I got tired of doing so (it took 62 cartridges for me to get there). I found four different rim thicknesses: 0.038, 0.039, 0.040, and 0.041 inches. I could see that the rim thicknesses were normally distributed with the cartridges sorted on my desk, but I thought it would be cool to prepare a bar chart and make that finding a bit more clear.

All the cartridge rim thicknesses I measured were within the SAAMI specification, but the SAAMI specification is liberal.

I headed to the West End Gun Club the next day with my most accurate .22 rifle, a beautiful CZ 452 Varmint model with a 14X Mueller scope.

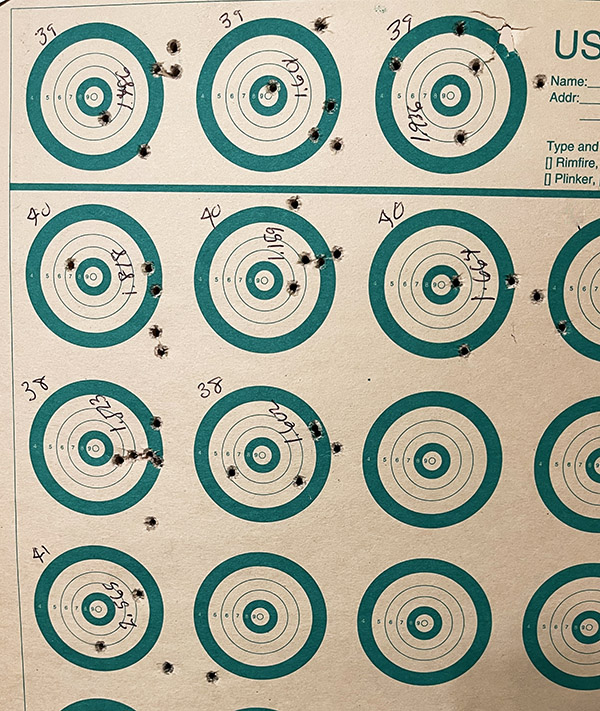

The plan was to shoot five-shot groups at 50 yards off the bench using the rim-thickness sorted Federal El Cheapo ammo. Here’s how that turned out:

All my shots felt right when the firing pin dropped, so I’m pretty sure that I wasn’t throwing the shots around due to poor technique. This rifle normally shoots much tighter groups at 50 yards with standard velocity ammo. The intent here was to see if I could get it to shoot better with cheap ammunition sorted by rim thickness.

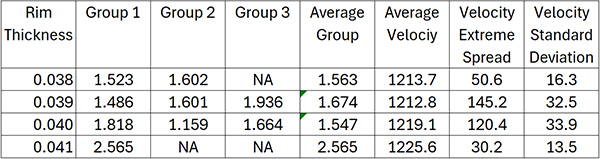

Here’s how it all shook out:

My take on the above data is:

-

-

- All the rim thicknesses I measured were well within the liberal SAAMI specification tolerance band.

- Not surprisingly, rim thickness is normally distributed (something I’ve found to be true for most manufacturing processes).

- Rim thickness, at least with my inexpensive Federal Value Pack ammo, has no effect on accuracy. Well, almost no effect; that last group with 0.041-inch rims jumped in size. But it was only one group. I looked for more 0.041-inch-thick rounds to test this again and I couldn’t find any.

- Rim thickness, at least with my inexpensive Federal Value Pack ammo, has no effect on average velocity.

- Rim thickness, at least with my inexpensive Federal Value Pack ammo, probably has no effect on velocity variation. Although the table above shows differences, it’s likely those differences would disappear if the sample sizes were larger.

-

Sorting by rim thickness is an interesting hypothesis, but my limited testing to assess the hypothesis shows it’s not worth the effort (at least with Federal Value Pack ammo). I have Remington and Aquila target ammo, and I’m going to measure rim thickness on those two brands in the next day or so to see if the rim thickness variability is lower. I’ll fire that sorted ammo through the CZ to see if the rim thickness hypothesis holds up with better ammo. It’s another good excuse to get out to the range (not that I ever need an excuse).

Stay tuned, my friends.

Never miss an ExNotes blog:

Of course I thought this was going to be about wheel rims.

How do u know the rim fitness doesn’t vary the width of the cartridge?

I don’t know that, Hack. More things to investigate and evaluate, I suppose.

Thats a lotta work for .22’s but I do appreciate the effort. 22’s are kinda like M&M’s – you just keep loading them in until the bag is gone. But with the exception of watching a YouTube video on how they are made I have never stopped to wonder what made them tick. Looking forward to the next report.

Thanks, Bob.

Stop by my website TriggerShims CZ page, there is much info there about matching headspace to rim thickness with Bolt Shims, it makes a little (HUGE) difference, little in the tiny improvements given these top guys are already very accurate, HUGE is the difference between a Win and a Second Place 😉

Awesome; thanks, Lance!

Nice interesting blog Joe. When I saw the SPI indicater in the fixture I perked up. Good equipment. As I read through your artical and results I thought to myself , now he needs to go back and try CCI or better ammo and see if results are different. Looks like your covering that too.

22 is fun.

Im currently working on a H&R 22 Special 9 shot revolver from 1934ish. Has problems not wanting to rotate the cylinder when trigger pulled and maybe 4 out of 9 shots dont go off. So your head thickness experiment has caught my eye.

Not sure how to fix the cylinder advance problem.

Revolvers are like clocks with springs and pawls and little things that dont take much to get out of time. Wonder if TJ has worked on older H&R

Revolvers? This one may end up on display self.

TJ does mail order work, Rob. If your H&R can be made to work, TJ is the man who can do it.

That cz needs a barrel cleaning possibly.

Well, there are a couple of schools of thought on that. One is that you have to fire a bunch of rounds through the barrel after it’s been cleaned before the real accuracy emerges. The other is that the barrel has to be absolutely clean. I’ve tried both and found that it doesn’t make any difference.