I don’t name my guns. Except for one. That’s Eleanor in the photo above.

I have a thing for big bore rifles, and chambered for the mighty .416 Rigby, Eleanor certainly qualifies. We don’t have too many elephants, rhinos, or cape buffalo in southern California. But if any ever become an invasive species here in the Peoples Republik, I’m ready. I’ve read all the African hunting stories, living vicariously through the adventures of folks like Theodore Roosevelt, Peter Hathaway Capstick, and others. It’s what prompted my path toward rifles like Eleanor.

But I digress. Back to the topic du jour. Sometimes you just wake up and think to yourself: I have to to load me some .416 Rigby today.

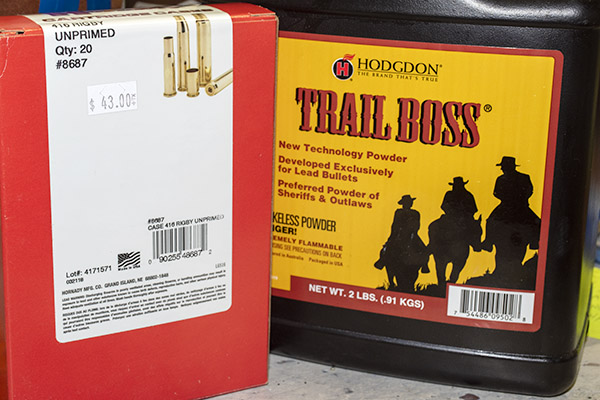

That’s what happened to me recently. I won’t get to shoot Eleanor for a few more days, but I thought I would share a few photos of the sausage-packing process involved in prepping .416 Rigby ammo. The drill on that fine day was for a couple of reduced-velocity loads using cast bullets and Trail Boss propellant. It’s going to be a fun day at the range when I light the candle on these puppies.

Reloading is sort of like cooking. You start with a recipe and the right ingredients. In this case, that includes .416 Rigby brass (something you don’t find laying around at the range) and Trail Boss propellant (which, like most reloading components, is pure unobtanium these days).

I’m well stocked with unfired, virgin Hornady brass and I used Montana Bullet Works cast 350-grain gas check projectiles. Because I’m loading cast bullets, the first step involved flaring the case mouth. I use the Lee universal flaring tool for this. You can see its business end in the photo below.

Here’s the Lee’s flaring die and a flared case mouth.

This is what the cartridge case looks like after it has been flared. You can see the diameter opens up slightly at the case mouth. This prevents shaving lead off the bullet base as it is seated in the brass cartridge case.

The Montana Bullet Works bullets are impressive. Actually, they are beyond impressive. I think they are perfect. They look more like machined parts rather than cast parts. I loaded their 350-grain flatnose cast bullets (they are 22 Brinell hardness linotype bullets) with a gas check base (take a peek at the next photo). The blue stuff is lubricant.

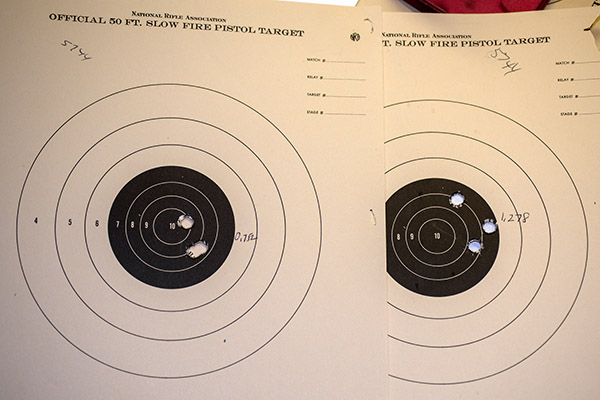

I’ve fired the Montana bullets before with 5744 propellant in Eleanor and they work well, as you can see on the targets below (I order my targets from Amazon). Those were 3-shot groups at 50 yards using the same Montana 350-grain cast bullets and 45.0 grains of 5744 propellant. Eleanor is an elephant rifle with iron sights, and I’m getting groups that would work well with prairie dogs.

There’s no leading with the Montana bullets. The Lyman cast bullet reloading manual (which I believe to be the best) lists 5744 and the 350-grain cast bullet as the most accurate load in this chambering (I like the Lyman

manuals better than any of the others).

The photo below shows a bullet just starting into the cartridge case. I had already seated CCI 200 primers into the cases.

Trail Boss is a reduced velocity propellant that is designed to occupy most or all of a cartridge case’s interior. It’s a light powder. The shape is unusual. The grains look like little washers.

Trail Boss is so big and fluffy my RCBS powder dispenser couldn’t throw a big enough charge with a single throw. I wanted to load these at 30 grains and 34 grains (suggested min and max with this propellant), so I set the powder dispenser to 15 grains (that’s what you see in the powder tray above) and threw two charges for each case, and then I did the same at 17 grains (again, throwing two charges for each case). According to the folks who make Trail Boss, the max load should not exceed the base of the bullet, and the minimum charge is 70% of the max charge. Here’s what a charged case with the max charge looks like.

I next seated the bullets. These cartridges are so long that you have to put the charged brass case into the shell holder, and then angle the bullet up into the die and set it back down on the case before you run the ram up. I do bullet seating and crimping in two operations. I’ll seat all the bullets to the required overall length without a crimp, and then I’ll adjust the die and run each round through again to get a good crimp. I use an old RCBS Rockchucker single-stage press I bought new in 1974. I’ve been using it ever since.

And here’s one last photo just to convey a sense of scale. From right to left, what you see below is a six-pack of .45 ACP cartridges in a moon clip ready for my 1917 revolver, a .45 70 round (I loaded some of those earlier today, too), and the .416 Rigby.

So how do these Rigby rounds shoot? I’m going to find out soon, folks, and I’ll let you know. Eleanor and I have a date at the West End Gun Club (don’t tell Sue). Stay tuned. It’s going to be fun.

More Tales of the Gun stories!

Order targets from Amazon.

Buy RCBS reloading equipment here!

Never miss an ExhaustNotes blog: Subscribe for free!