By Joe Gresh

I’ve gotten an undeserved reputation as a China booster. Some Internet wags think I work for China and must be getting a cut from the sales of products I test. Any time you guys want to get serious and ban all products from China let me know. I’m with you, man. I wish I got a cut from the sale of Chinese imports but the truth is, many times Chinese stuff is the only stuff I can afford. Take this Vevor welding table I bought on Amazon. At $62 including shipping it was even cheaper than the Harbor Freight welding table that looks like the exact same unit.

For fun I tried to find a similar sized, made-in-USA, welding table and the cheapest one I could find was from a company called Siegmund. The Siegmund table is way, way nicer than the Vevor and it comes with a bunch of clamping accessories included. The Siegmund costs $2569.00 plus shipping. For me, the choice isn’t made-in-USA vs made-in-China: the choice is a cheap welding table or no welding table at all.

Maybe if I ran a welding shop I’d bite the bullet and get the Siegmund, but that’s not exactly true. If I ran a welding shop I’d probably make my own welding table. It doesn’t matter for this product review because I don’t run a welding shop and I never will.

My previous welding table was a small, outdoor side table made from expanded metal mesh. It was too low and I was on my knees to do the welding. Everyone knows you have to be in a comfortable position to lay down a steady bead, more so when you can’t weld very well in the first place.

The Vevor welding table is one of those generic designs that are manufactured by many different factories in China. It has a tilting feature that I don’t foresee using but you never know. Out of the box the table comes complete with all the nuts, bolts, and screws needed for assembly. It’s easy to put together. It took me only 45 minutes and I’m a slow learner.

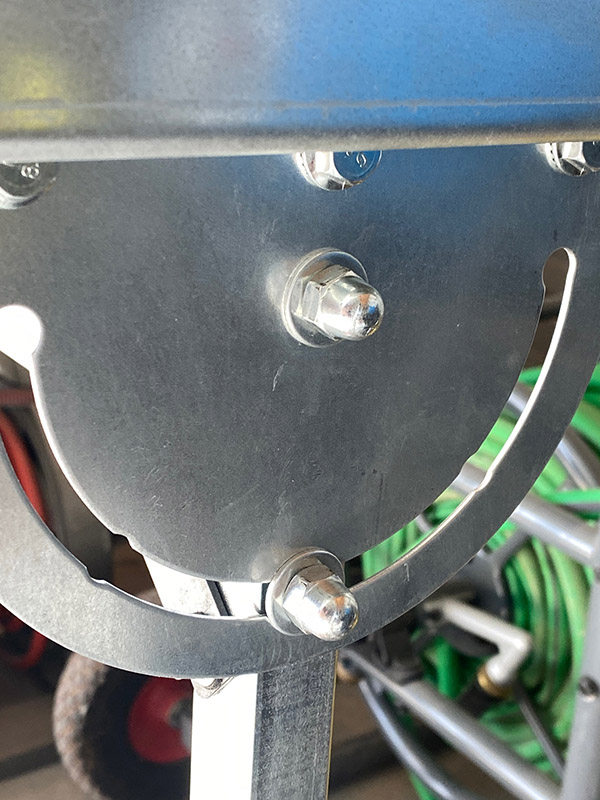

As delivered, the table worked fine, but there were several tiny modifications that made the thing much better. The tilting arc has two wing nuts and two plastic knobs on each side to lock the table in position. It’s almost impossible to get these fasteners tight enough to prevent the table from slipping when you push on the edge. It’s probably not a problem for welding but I replaced the factory hardware with acorn nuts. Once the acorn nuts are tightened with a wrench the table no longer slips.

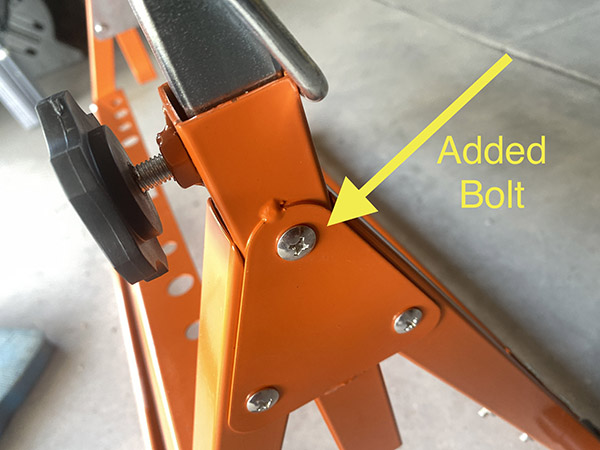

I like my welding table high so that I have a better chance of seeing what I’m doing. The Vevor comes with two pins that allow height adjustability but even in the highest setting it was too low. If you weld from a chair it would be ok. I extended the table another inch and drilled the upright for a bolt/screw. To lower the table, I’ll have to remove the bolt but it will only take a moment.

I added two side braces to take a little side to side wobble out of the table. It’s relatively stable now.

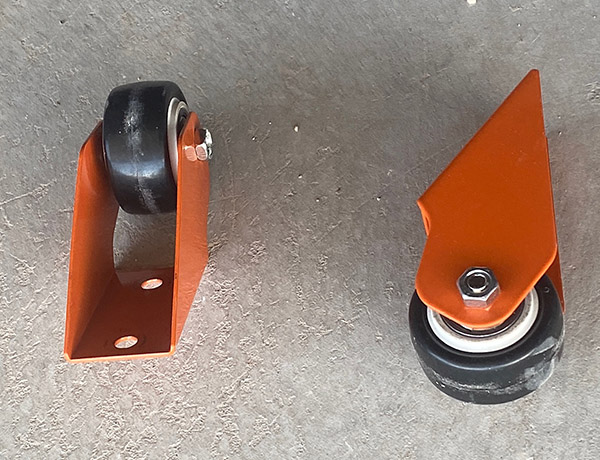

The Vevor table folds for storage and came with wheels to roll the thing around. I didn’t use the wheels as the table is not very heavy and you can lift it easily.

The feet on the Vevor are an odd setup. Four plastic pieces fit into the ends of the legs and two crossbars with rubber tips snap into the plastic pieces. The crossbars fall out of the plastic easily so I drilled and added 4 screws to hold them in place.

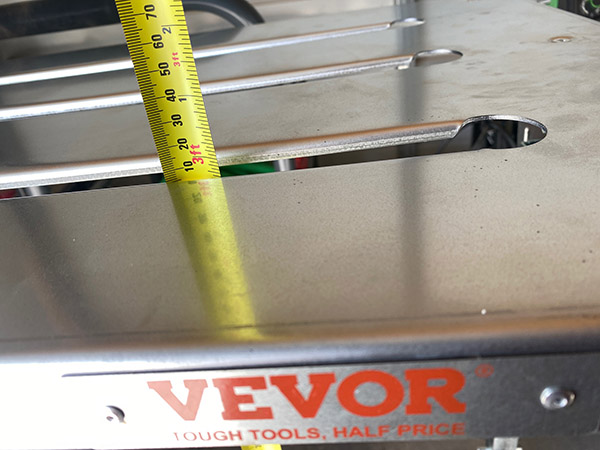

Once I modded the Vevor welding table it felt sturdy. There are a few neat and not so neat features. The tabletop has slots for clamps but is not very thick metal (it’s about 2.4mm). It racks pretty easy until you flatten it out and tighten the tilt nuts. For electric welding it will probably be okay; gas welding may warp the top. On the sides are fences that you can raise beyond the tabletop to provide a handy place to clamp your work. Lowered, the fences are out of the way and razor sharp so watch your elbows. The lower cross brace on the Vevor comes with several size holes for tool/clamp storage and a couple loops to hang whatever you want to hang.

For a measly $62 you get a lot of welding table from Vevor. I’m satisfied with the thing and as soon as I clear out all the flammable stuff lying around the shed I’m going to test the table under real life conditions. Watch this space for a follow up report.