By Joe Berk

Like that photo you see above? Yeah, me, too. I took it on the parade grounds at Fort Knox, Kentucky, a few years ago. I used to run the Composite Structures plant that made rotor blades for the Apache helicopter. It was one of the best jobs I ever had.

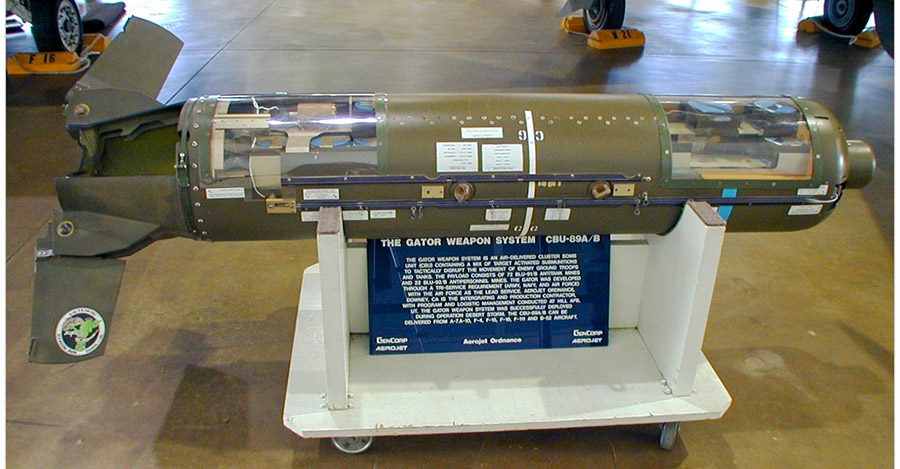

We recently reposted (under the Wayback Machine banner) our blog about the Gator mine system, and in it I promised to write about the Apache main rotor blade failures. This is another defense industry failure analysis war story that crosses company lines and supplier/customer boundaries, and I’m not entirely sure that there wasn’t some nefarious behavior going on at McDonnell Douglas. I’ll tell you what happened and you tell me.

During the Vietnam War, the Army (my alma mater) found that the Huey helicopter had a few shortcomings. I guess that’s to be expected; it was the first time the Army used helicopters in a major way in a real war. The Huey was susceptible to small arms fire (and big arms fire, too, for that matter) and it was noisy. On a clear night, you could hear a Huey coming in from a long way out with its characteristic “wop wop wop” signature as it beat the air into submission. That “wop wop wop” sound was actually the rotor tips breaking the sound barrier on the left side of the helicopter, so the Army knew it had to do something to get the blade tip speed below the speed 0f sound on its next-gen helicopter. Another big problem was small arms fire; a single .30-caliber AK-47 bullet through a Huey rotor blade would destroy the blade’s structural integrity (and there were a lot of AK-47 rounds in the air in those days). When that happened, the helicopter and its crew were lost. There could be no autorotation (you can’t autorotate without a blade) and you couldn’t bail out. The next-gen helicopter blades would have to be impervious to small arms fire.

Fixing the blade tip speed problem was simple. Instead of having two blades like the Huey, the Apache went to four blades. That cut the rotor speed and let the blade tips go subsonic. “Wop wop wop” no more. Easy peasy.

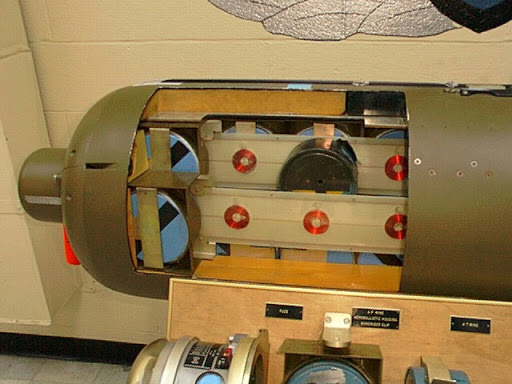

The structural integrity issue was the more significant challenge. The engineers at McDonnell Dougas (the Apache prime contractor) designed a blade that had four spars that ran longitudinally (with the length of the blade) contructed of AM455 stainless steel (a special blend used on the Apache and, at the time, nowhere else). The spars had overlapping epoxy-bonded joints that ran the length of the blade. The idea was that a hit anywhere on the blade (up to and including a 23mm high explosive Russian anti-aircraft round, roughly the explosive equivalent of a hand grenade) would damage that spar, but the remaining three spars would hold the blade together. It worked. An Apache blade actually took a blade hit from an Iraqi ZSU-23/4 and made it back to base.

So here’s the problem: The Army specified a blade life of 2200 hours (blades on a helicopter are like tires on a car…they wear out), but our blades were only lasting about 800 hours before the blades’ bondline epoxy joints holding the spars together starting unzipping. It wasn’t a catastrophic failure (the helicopter could still fly home), but the blades had to be repaired. The Army would send the blades back to McDonnell Douglas, and McDonnell Douglas sent them back to us at Composite Structures for refurbishment. If they couldn’t be repaired, we sold McDonnell Douglas a new blade (back in the 1990s, each blade cost just north of $53,000, and McDonnell Douglas put a hefty markup on that when they sold the blade to the Army). When they could be repaired, we still charged a hefty fee.

When I entered the picture as the plant manager, I learned that both Composite Structures (my company) and McDonnell Douglas (my customer) had made half-assed efforts to fix the blade problem, but neither company was financially motivated to eliminate it. We were making good money selling and repairing blades and so was McDonnell Douglas. The Army, however, was taking it in the shorts.

This was also a major problem for me as the manufacturing guy. I didn’t like having to make two blades to get one good one. We were rejecting one of every two blades we made for spar disbonds in the factory. You read that right: We had to make two blades to get one good one. Because of this, we were in a severe past due delivery condition, and my mission was to correct that situation. So we went to work on solving the problem. We found and fixed plenty of problems (blade cure profile issues, cleanroom assembly shortfalls, epoxy shelf life and pot life issues, nonconforming components issues, and contamination issues), but the blade disbonds continued. McDonnell Douglas continued to pound us for quality issues, all the while secretly smiling all the way to the bank as they continued to sell twice as many blades as they should have been selling.

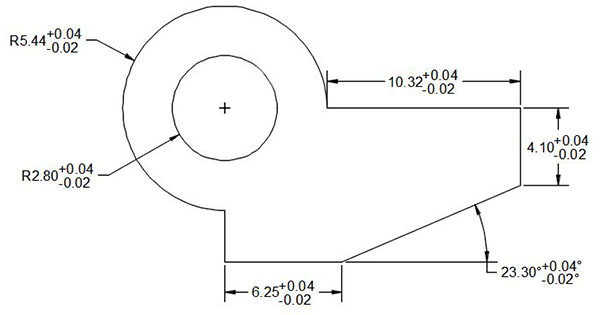

We went through everything and finally concluded that there had to be a design issue with the blades; specifically, that the bondline width where the spars were glued together had too much variability. If that glue line was small enough, we reasoned, it wouldn’t hold up and the blade would disbond. We asked McDonnell Douglas about that (McDonnell Douglas was responsible for the design; we were building it to their engineering drawings), but they kept blowing us off. The bondline width wasn’t dimensioned on the McDonnell Dougas drawings. The other parts were, and McDonnell Douglas’ idea was that if the blade parts met their drawing requirements, the bondline width would be okay. That’s what they hoped for, anyway. But you know what they say about hope. You can poop in one hand and hope in the other, and see which one fills up first.

I asked for a meeting with our company and McDonnell Douglas on the blade failures, and they wouldn’t meet with us. So I sent out another invitation, and this time I included the Army. McDonnell Douglas was livid when the Army quickly said yes; now, the McDonnell Douglas wizards had to meet with us on this issue. That meeting started about like I expected it to, with McDonnell Douglas tearing us a new one on the blade failures, telling us our quality was terrible, and basically letting me and the rest of the world know that, in their opinion, things had gone downhill since I had taken over as plant manager (no matter that this 50%-rejection-rate blade issue had existed for a dozen years prior to my arrival). I patiently explained the issues we had found and corrected, and then emphasized that the problem with blade separations had continued unabated. I then asked the McDonnell Douglas program manager about the bondline width and the fact that this apparently critical requirement was not on their engineering drawings. He denied it was the issue and went off about our poor quality again. When he ran out of steam, I asked the question about the bondline dimension yet again, and specifically, how narrow the bondline could be and still provide an adequate joint. There were more accusations about our lousy quality (the guy only knew one tune and he loved singing it), and I again waited for him to finish. When I asked the question a third time, before McDonnell Douglas lit up about our poor quality again the Army representative asked “yeah, how narrow does it have to be before the blade fails?”

The McDonnell Douglas guy stared at me like cobra looks at a mongoose (I’ve only seen this in YouTube videos, but I’m pretty sure the analogy is a good one). He sputtered and stammered and I think I saw a little spit fly from his mouth. “If you make it to the drawing it will be okay,” he said. I mean, under the circumstances it was the only thing he could say. I almost felt sorry for him, in the same way you feel sorry for a rat when a red-tailed hawk is swooping down with talons extended. You feel bad, but you look forward to seeing the hawk doing his thing.

The Army guy sensed this was something big. “How low?” he asked again. If there is such a thing as a perfect impersonation of a deer caught in the headlights, the McDonnell Douglas dude was nailing it. It was what we in the literary world call a pregnant pause, one of those “what did the President know, and when did he know it?” moments. As I type this, I can remember the scene like it happened 10 minutes ago, but it’s been close to 30 years.

“0.375 inches,” the McDonnell Douglas dude finally answered. He actually said the zero in a half-assed attempt to add engineering gravitas to his answer. “As long as they build it to the print, they’ll be okay,” he added, with a “so there” smirk. He was answering the Army man, but the smirk was all for me.

What the McDonnell Douglas guy didn’t know was that my guys could see the bondline width in an x-ray, and we x-rayed every blade returned for repair. And I guess he didn’t realize how easy it was to do a tolerance analysis to show what the drawings allowed the bondline width to be.

What happened next was one of those moments I’ll remember for the rest of my life. I looked my engineering guy and my QA guy. They knew what I wanted. They both left the room. Fifteen minutes later they were back. My engineering guy handed me the results of his tolerance analysis. The McDonnell Douglas engineering drawings tolerance stackups allowed the bondline width to go as low as 0.337 inch. The QA guy had even better information. All the blades that had been returned to us for spars unzipping (which was the only reason we ever saw a blade returned) had bondline widths less than 0.375 inches (McDonnell Douglas’ admission for the lower limit) but above .337 inches. In other words, our quality was fine. The failed blades met the McDonnell Douglas engineering drawings but were below the value I had finally prodded McDonnell Douglas into revealing.

I could have been more diplomatic, I guess, but that wasn’t me. I shared that information with the room. The Army rep smiled. “I think you guys might want to continue the meeting without me,” he said. And then he left.

The McDonnell Douglas guy exploded as soon as the door closed. He was apoplectic (I looked that word up; it means overcome with anger and extremely indignant, and that was him). McDonnell Douglas had been screwing the Army for years with a deficient design and now it was out in the open. They were potentially exposed to defective design claims from the Army (and from us) for hundreds of millions of dollars. Think about it: 12 years of Apache blade production, a 50% failure rate in production, a blade life of only 800 hours (against the Army’s spec requirement of 2200 hours), and the fact that we and McDonnell had factored all that waste into our pricing.

Fortunately for McDonnell Douglas, the Army wasn’t interested in suing them (all they wanted was good blades). My boss wasn’t interested in pursuing a claim against McDonnell Douglas, either, as they were our bread and butter and he wanted to keep the business. We fixed the problem by holding the blade components to tighter tolerances (tighter than McDonnell Douglas had on their drawings) so the bondline width would always be above the magical 0.375 inch, and we never had a blade unzip in production again. McDonnell Douglas did not correct their drawings, as it would have been an admission of guilt on their part that would absolutely guarantee a loss if the Army ever took them to court.

So there you have it: The Apache main rotor blade failures, all caused by sloppy engineering at McDonnell Douglas. It’s hard to believe that the blades had a 50% failure rate and didn’t meet the Army’s specified blade life for a dozen years before the problem was fixed, but that’s what happened. It’s also hard to believe that nobody at McDonnell Douglas went to jail for it.

Never miss an ExNotes blog: