As mentioned in a previous ExhaustNotes story titled “Guilt Trip,” our water well at the ranch has become unreliable. In order to quickly bring some stability to the situation we decided to install a storage tank and re-shuffle the way water is delivered to our shack.

After pouring a slab to support the new, 3000-gallon water tank we had the local Tank Guy deliver Big ‘Mo to the ranch. Big ‘Mo cost $2800 delivered to our door and that’s a bit expensive but it seems like everything costs more since the Covid crisis eased up. Home Depot has a 2500-gallon tank that is slightly lighter construction for $2300 plus $80 delivery plus tax so the per gallon price is comparable. Buying local means the Tank Guy will spend his money locally. Anyway, I don’t like the way our local Home Depot stores their tank inventory. They put the tanks on their sides instead of the bottom. This makes it easier to move the tanks with a forklift but I suspect it does the tank no good having all the weight where it’s not designed to go.

The Tank Guy stores his tanks upright, just north of Tularosa in a big field across from the railroad overpass. Our tank showed up securely strapped to a trailer…on its side. But only for the time it took to arrive at the ranch. These tanks look huge but they are rotocast plastic and are not that heavy. The 3000-gallon tank weighs 500 pounds. It took the Tank Guy, the Tank Guy’s wife and me to slide the tank up a ramp I handily screwed together earlier for pouring the tank slab.

I installed two ball valves in the bottom of the tank, one ¾-inch for the output and one ½-inch to fill the tank. Tank filling can be done three ways: by water delivery truck, gravity fed from the upper level shed storage tank, or by pumping well water into the tank. A jumble of shut-off valves can be juggled to pressure feed the house from the well, from Big ‘Mo via a centrifugal pump or by gravity from the upper level storage. I’m into redundancy when it comes to water.

If you live in areas that freeze you’ll want to add a pipe heater and insulate any exposed pipe. The black tank helps keep the water from freezing and when the sun comes out we rarely get days under 40 degrees so water freezing in the tank has not been an issue so far.

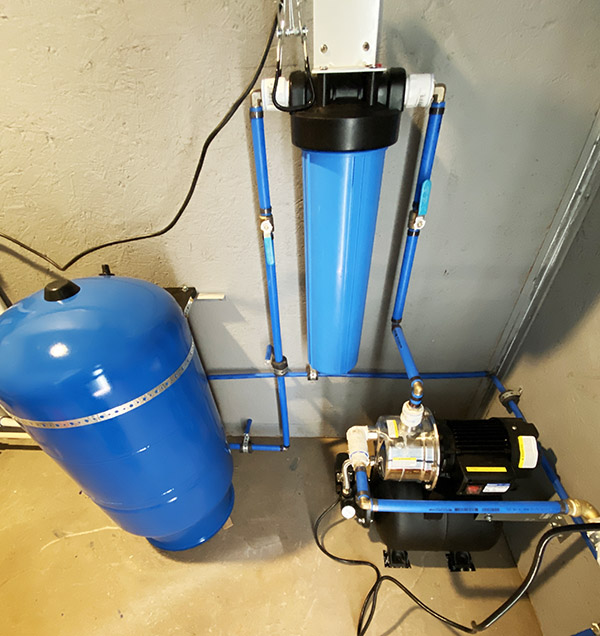

I took this re-plumbing opportunity to eliminate the water softener and reduce the size of the very old well pump expansion tank. The water softener periodically runs a flush cycle and being on a fixed water supply we can’t waste water like that. The bladder inside the big expansion tank became porous over the years and water had migrated to the dry side causing rust. Plus it was too damn big. I’m thinking it will make a great stand alone fireplace or smoker.

From Big ‘Mo water is piped through a mesh screen filter, a one-way check valve and into a centrifugal pump that provides 40psi of pressure to a large 5-micron filter and on to the house plumbing. The pump has its own small expansion tank that seems to keep a fairly steady flow of water to the fixtures. You can see the flow increase a bit when the pump cycles but nothing a rough, tough, couple of pioneers like CT and I can’t handle.

Since we’ve moved from hot, humid Florida to a colder climate I’ve learned that PVC plumbing is not ideal in freezing conditions. Going forward I’m trying to use PEX plumbing in all my projects and I’ve been happy with the results so far. PEX uses a more flexible pipe that is crimped onto brass PEX fittings with brass/copper-ish crimp rings. You’ll need a special PEX crimp tool to compress the rings onto the PEX fittings. Once crimped, you can spin PEX pipe on its brass fitting (within reason) without causing a leak. I haven’t had one PEX-related leak yet, even when tight working conditions result in a less than optimal crimp. I wish I could say the same for the PEX-to-threaded-pipe connections. One thing to keep in mind is that PEX pipe is not UV resistant so cover any pipes that will see sunlight.

Like most plumbing systems PEX has to be cut and pipes replaced if you need to change anything. You’ll need a PEX removal tool if you want to reuse the brass PEX fittings and why wouldn’t you want to reuse them? The ability to reuse PEX fittings is a big deal. When is the last time you were able to reuse a glued PVC fitting or soldered copper fitting? The removal tool cuts the crimp ring without cutting into the PEX barb. Once the ring is out of the way you can crimp V-shaped depressions around the bit of PEX stuck on the barb. Crimping the Vee’s causes the PEX pipe circumference to expand and the pipe will slide right of the barb without causing undue stress.

It’s a bad feeling when your well runs dry. All of a sudden your shack becomes unlivable. But by building in a little extra infrastructure we have water security even if it means buying water from our local water delivery service. And I have plans on the table for catching much more rain during the next monsoon season that will nearly eliminate our reliance on bought water.

Do us a solid and click on the popup ads!

Never miss an ExNotes blog: