By Joe Gresh

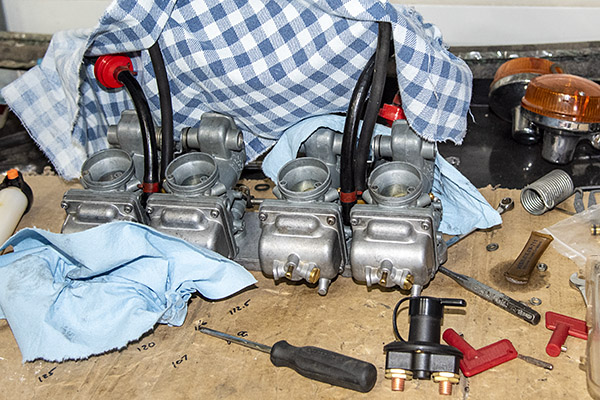

I’ve been so busy with home-nesting projects my motorcycles have succumbed to time’s crumbling embrace. I parked the ZRX1100 Kawasaki after the carburetors clogged up and it began running on three cylinders. Since it has been sitting a few years naturally the brake pistons seized. Followed by fluid leaking out of the calipers. Followed by me robbing the battery to start the generator that powers the nest. In any event, it needed tires, a chain and sprockets and the throttle cable repaired. So the big green Eddie Lawson lookalike has suffered the indignity of being dragged across the countryside on a two-hundred-dollar Harbor Freight trailer.

Even worse, the mini bike my pops built for me when I was a wee lad is on the injured reserve list. Forty-eight years idle, Mini has untold issues although the Briggs and Stratton engine still turns over. I’ve lost a few critical, hand-made parts and since the Old Man has shuffled off I’ll have to re-make the stuff myself. It’s not easy handling such a precious thing. The mini is lousy with my father’s engineering and artistic skills. The welds and frame geometry are a direct, tangible link to happy times working together in the garage.

The 1965 Honda 50cc went under water in one of Florida’s many hurricanes so I took it apart and threw everything into boxes and plastic tubs. It’s been apart so long the tubs have crystalized into the finest, most fragile parts bins in existence. The slightest touch turns them to dust. Dry, chalky plastic oxide mingles with 4mm JIC screws and yellowed wings. The sheet-metal swing arm rusted completely in half so I’ll have to rig something in aluminum to secure the rear wheel to the frame and lower shock eyes. I do have a good engine for the Honda: a fire breathing 140cc Lifan clone that clears the front fender by a quarter-inch.

The newest dead-bike I own is a Husqvarna. On the last, long-ish motorcycle ride I took to Big Bend Park way down in south Texas the Husqvarna SMR510 lost its clutch release. Bit by bit, little by little the clutch action faded away until finally pulling the clutch lever had no effect on events. The headlight also broke off but on a dirt bike that’s hardly worth mentioning. We were doing some trail riding down there and the Husky did ok shifting motocross style. Starting out was the main problem as you had to push the thing, jump on, and pop it into first. The bike would either stall or roar off on a wheelie. On the ride home I would circle the backfield waiting for traffic lights to change. Sorry, everyone in El Paso.

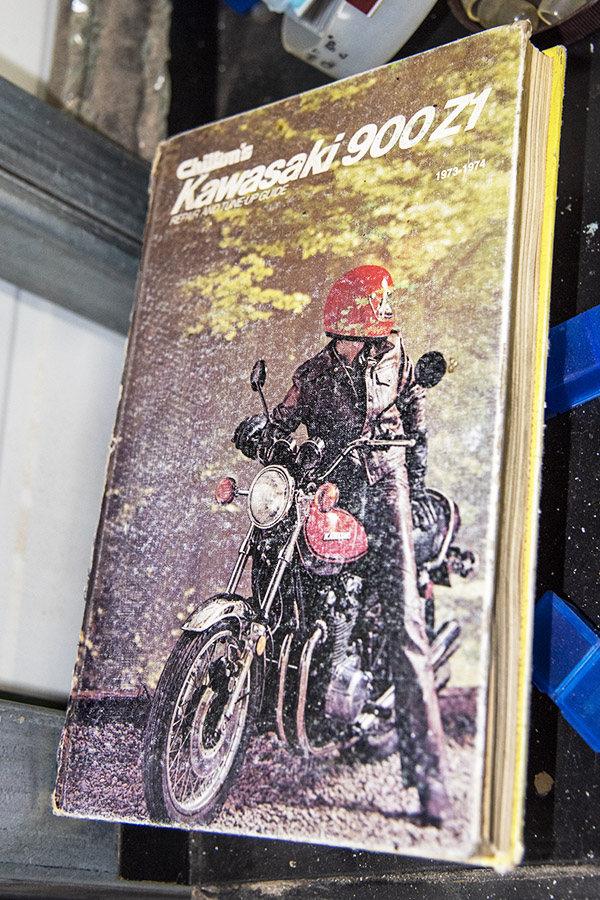

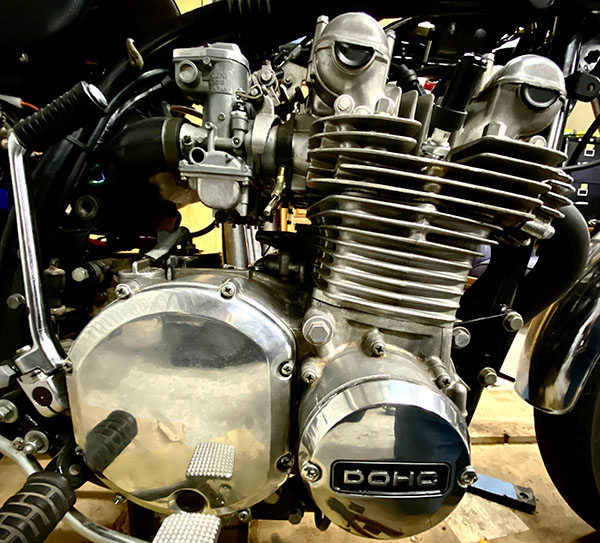

At least the Z1 Kawasaki never ran for me. I bought it from the owner of the property we now live on. I had to get it out of there because things were disappearing and I felt someone was going to pilfer the Z before I could. The Z needs all sorts of stuff but I get the feeling this bike will be a keeper. The lines are so clean and simple compared to modern bikes. It sits damn near perfect, doesn’t feel heavy and I know from following David Howell through the Everglades, Z’s do well in the dirt.

Which leaves us with the only motorcycle I own that works: a 360cc, 1971 Yamaha RT1B. Fondly known as Godzilla to dirt riders far and wide, the old Yamaha just keeps popping along. Analog everything, smoky, noisy, sweating petroleum from every pore, this is the bike that will not die. Even with me maintaining it.

Everything around us is constantly falling apart. Even the Great Pyramid in Egypt will be a sand dune one day. I just hope that when it finally falls to the ground replacement parts will still be available on Ebay.

Help us keep the lights on…please click on the popup ads!

Never miss an ExNotes blog:

Here at ExhaustNotes.us we are all about the motorcycle, with a smattering of gunplay and interesting adventure destinations thrown in to keep the place hopping. But what if there were no bikes, adventures or bullets? What then? Keep reading and I’ll tell you what then, Bubba.

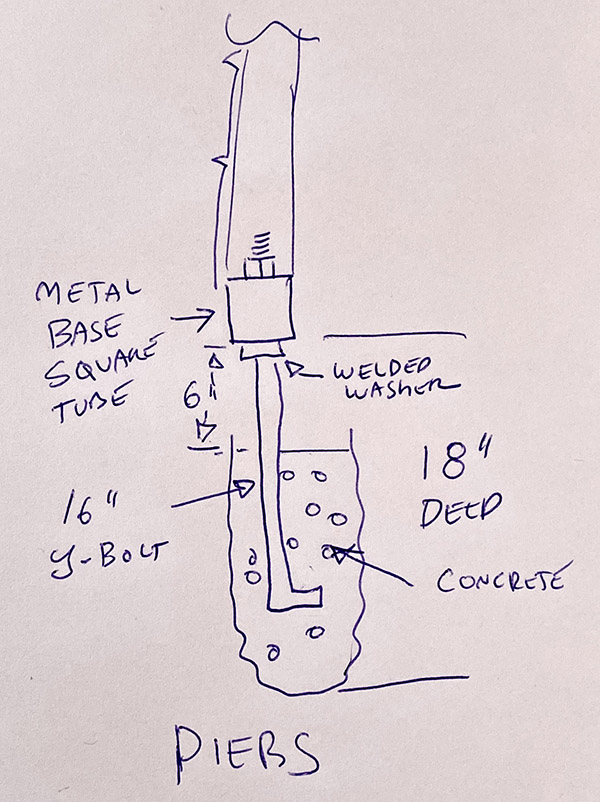

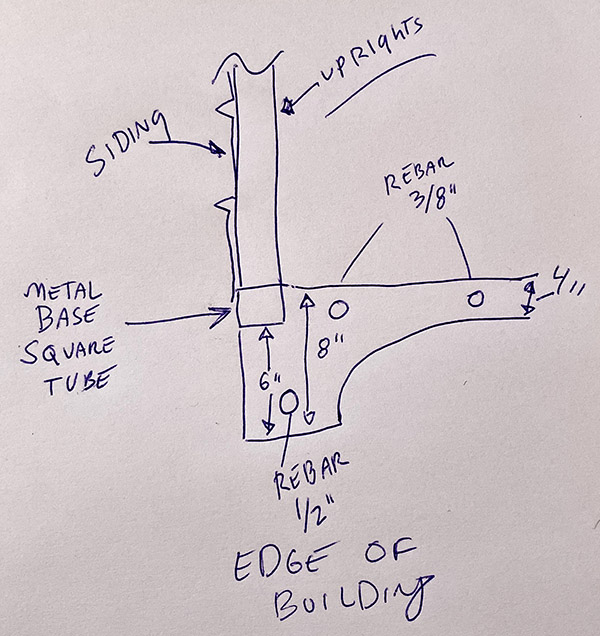

Here at ExhaustNotes.us we are all about the motorcycle, with a smattering of gunplay and interesting adventure destinations thrown in to keep the place hopping. But what if there were no bikes, adventures or bullets? What then? Keep reading and I’ll tell you what then, Bubba. Situated in the steep-ish foothills of the Sacramento Mountains, Tinfiny Ranch is slowly bleeding into the arroyo, you know? You put down your cold, frosty beer and the next thing you know your Stella is halfway to White Sands National Monument. On the lee side of The Carriage House we’ve lost a good 18-inches of mother earth because while it doesn’t rain often in New Mexico when it does rain it comes down in buckets. This sudden influx of water tears through Tinfiny Ranch like freshly woken kittens and sweeps everything in its path down, down, down, into the arroyo and from there on to the wide, Tularosa Valley 7 miles and 1500 feet below. Claiming dominion over the land is not as easy as they make it sound.

Situated in the steep-ish foothills of the Sacramento Mountains, Tinfiny Ranch is slowly bleeding into the arroyo, you know? You put down your cold, frosty beer and the next thing you know your Stella is halfway to White Sands National Monument. On the lee side of The Carriage House we’ve lost a good 18-inches of mother earth because while it doesn’t rain often in New Mexico when it does rain it comes down in buckets. This sudden influx of water tears through Tinfiny Ranch like freshly woken kittens and sweeps everything in its path down, down, down, into the arroyo and from there on to the wide, Tularosa Valley 7 miles and 1500 feet below. Claiming dominion over the land is not as easy as they make it sound. After the wall is up the resulting divot will require filling with dirt. I have lots of dirt on Tinfiny Ranch; the conundrum is where to borrow it from without causing even more erosion. I’m hoping that leveling the back yard will provide most of the needed fill.

After the wall is up the resulting divot will require filling with dirt. I have lots of dirt on Tinfiny Ranch; the conundrum is where to borrow it from without causing even more erosion. I’m hoping that leveling the back yard will provide most of the needed fill.

It seems like I’m always working a pick and a shovel at Tinfiny Ranch. Situated at 6000 feet in the foothills of the Sacramento Mountains the place is steep with many elevation changes. An arroyo runs past the house so that when it rains (and it rains a lot in New Mexico) my driveway becomes a short-lived trout stream.

It seems like I’m always working a pick and a shovel at Tinfiny Ranch. Situated at 6000 feet in the foothills of the Sacramento Mountains the place is steep with many elevation changes. An arroyo runs past the house so that when it rains (and it rains a lot in New Mexico) my driveway becomes a short-lived trout stream. We had a day to kill before I picked up the tractor so we went to Hunter’s Skybox at OSU and watched the OSU women’s basketball team dismantle a team from Kansas. The governor of Oklahoma has a suite two doors down and there was unlimited free food along with all the ice cream you could eat. The suite had a commanding view of both the football field and the indoor arena.

We had a day to kill before I picked up the tractor so we went to Hunter’s Skybox at OSU and watched the OSU women’s basketball team dismantle a team from Kansas. The governor of Oklahoma has a suite two doors down and there was unlimited free food along with all the ice cream you could eat. The suite had a commanding view of both the football field and the indoor arena. The Tractor was a beauty with tires so new they still had rubber bar codes visible. Kubota’s have earned a good name in the heavy equipment arena and this L2850 sported a diesel engine that fired right up.

The Tractor was a beauty with tires so new they still had rubber bar codes visible. Kubota’s have earned a good name in the heavy equipment arena and this L2850 sported a diesel engine that fired right up. Underneath the driven front end you’ll find a portal-type axle to give the tractor plenty of ground clearance. Everything is leaking a bit but oil is cheap and Tinfiny can use a little dust control. The steering felt tight and Woody, the guy I bought the tractor from takes good care of his stuff.

Underneath the driven front end you’ll find a portal-type axle to give the tractor plenty of ground clearance. Everything is leaking a bit but oil is cheap and Tinfiny can use a little dust control. The steering felt tight and Woody, the guy I bought the tractor from takes good care of his stuff. When I worked construction in Miami it was rare to see a dashboard unbroken. Vandalism was a constant problem. Lights, tires and hoses were routinely damaged by bored kids. The L580 dash was clean and everything works except the tach needle fell off.

When I worked construction in Miami it was rare to see a dashboard unbroken. Vandalism was a constant problem. Lights, tires and hoses were routinely damaged by bored kids. The L580 dash was clean and everything works except the tach needle fell off. At the rear of the Kubota has a two-speed PTO drive that I will be using as soon as CT buys me a backhoe attachment. Amazon has some cool 3-point hoes costing around $3600. You don’t want to do a lot of side digging with a 3-point hoe because the hitch wasn’t meant for big side loads but as long as you are crabbing in a straight line they will work well.

At the rear of the Kubota has a two-speed PTO drive that I will be using as soon as CT buys me a backhoe attachment. Amazon has some cool 3-point hoes costing around $3600. You don’t want to do a lot of side digging with a 3-point hoe because the hitch wasn’t meant for big side loads but as long as you are crabbing in a straight line they will work well. The transmission has high and low range with low range, first gear being super slow. Top end of the tractor in high range-high gear is around 12 miles per hour. With zero suspension 12 MPH is plenty over Tinfiny’s rough grounds.

The transmission has high and low range with low range, first gear being super slow. Top end of the tractor in high range-high gear is around 12 miles per hour. With zero suspension 12 MPH is plenty over Tinfiny’s rough grounds. This lever engages the front wheels. This is pretty important because the front end loader combined with nothing attached to the hitch means the big rear wheels have little traction.

This lever engages the front wheels. This is pretty important because the front end loader combined with nothing attached to the hitch means the big rear wheels have little traction.