I’ve been on a tear lately. The shed floor is nearly done and I’m laying down some slabs, man. That doesn’t mean I haven’t managed to sneak in a little tinkering on the 1974 Yamaha Rd350. I mean, once the slab is poured and finished you’ve got to let it cure for a day. Green concrete is very fragile.

I wanted to drain the RD 350’s fluids before getting too far along. Which was kind of good because I discovered the oil tank wasn’t slotted into the rubber frame peg correctly. That meant taking out the battery to access the oil tank bolts.

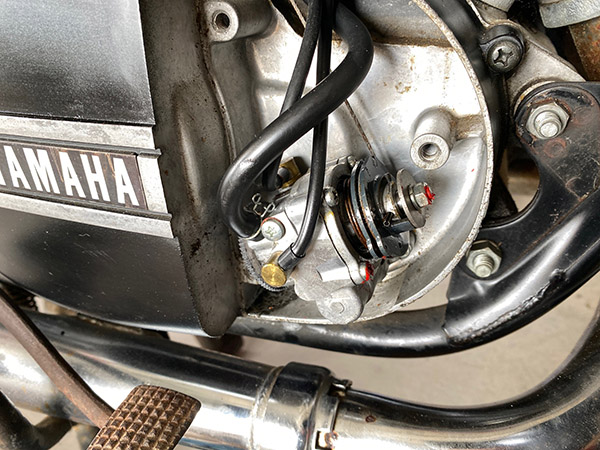

It was no trouble at all to pull the tank, drain it and re-slot it onto the frame peg. The original feed hose drooped underneath the carburetors then rose over the clutch cover forming a trap. I didn’t like the looks of the trap so I shortened the feed hose a bit and routed it without a loop.

When I pulled out the battery to fix the oil tank I noticed the top of the battery had a melted spot. This melted spot corresponded with a melted positive wire to the battery. I suspect the battery is the wrong one. It looks too tall and there was a section of old inner tube covering the battery. I see no evidence of arcing on the seat pan but something melted the positive wire as it has been wrapped with electrical tape.

After refilling the oil tank I needed to bleed out any air in the feed line to the autolube pump. The pump area was shockingly clean. It looked like a new motorcycle inside.

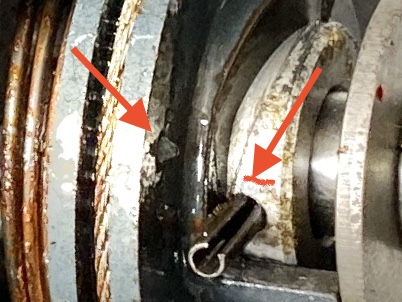

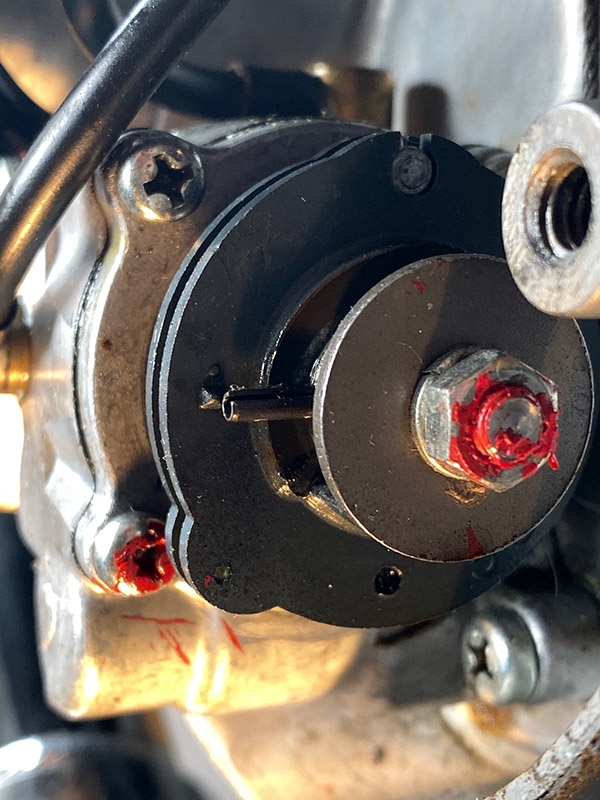

I sent Deet photos of the pump as I was well pleased and wanted to show the thing off. Zooming in on my photo Deet noticed that the autolube pump was not adjusted correctly. The pin and dot are supposed to line up at idle.

The oil pump cable was adjusted as loose as the lock nuts would allow. This RD is near perfect except where mechanics have fouled it up. Resetting the pump was quick and now the pin lines up with the mark at idle.

The chain guard was sort of floppy because the front mount was missing its bolt and the rubber bushing, along with the spacer. I cobbled one together from bits and pieces; it will work until I find the correct parts.

The more I mess with the RD350 the more amazed I am at how unmolested it is. All the case screws look perfect (except for the ignition and pump screws). Opening things reveals factory fresh assembly. It’s almost too perfect: I’ve got to up my mechanical game to treat this motorcycle with the care it deserves.

More on the RD350 story and other Joe Gresh Resurrections is here!

Never miss an ExNotes blog…sign up here for free!