By Joe Gresh

The famous line was from a Clint Eastwood movie, I think, but regardless it rings true for me as I ease into my salad years. Or is that my pabulum years? Recently I did a few simple mathematical equations and then ran the results through my life expectancy chart. The results were not encouraging. I would need to live another 124 years, 7 months to complete all the projects I’ve started. That’s if I didn’t gain any additional projects in the ensuing 124 years. Unfortunately, the projects still drift in by ones and twos. It’s time I got to know my limitations.

I was building the driveway retaining wall at The Ranch when the epiphany came. I looked around at the tools spread around the front yard, the stack of lumber and the pallets of concrete and decided that there was just no way to do it all and that I needed to shed a few projects. At least get them off my books. The low hanging fruit was first to go.

The 1974 MGB-GT was a candidate because I haven’t spent much money on it yet and it’s a huge, time consuming proposition. It needs many, many manhours and truthfully I never really wanted a MGB-GT anyway. It was just on the land when we bought the place and I thought it was a cool looking car. I bandied about about selling it but the prospect of wading through all the Internet scammers and tire kickers didn’t appeal to me. My buddy Mike from the Carrizozo Mud Chuckers expressed an interest in the car so I made him a deal he couldn’t refuse: I gave it to him.

Before you get all wound up and start telling me how you would have given me $500 for the car I have this to say: “No, you wouldn’t.” Just like you wouldn’t buy a Janus if it had an American made V-twin engine or an electric car if it went 100 miles further on a charge. Mike has a trailer that fit the MBG perfectly and we loaded it up using two come-alongs in series. With 3 flat tires it took about a half-hour to move the car 20 feet. Inches add up to miles and the blue, MGB is now residing 69 miles away at Mud Chuckers central. Seeing the car roll off the property gave me a real lift. It’s like I bought an extra year of my life.

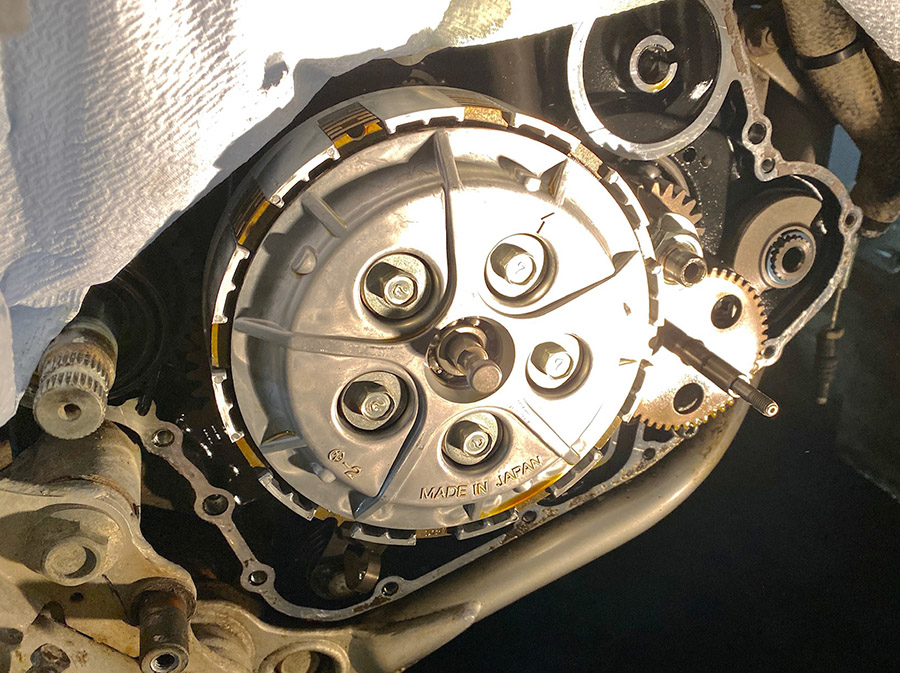

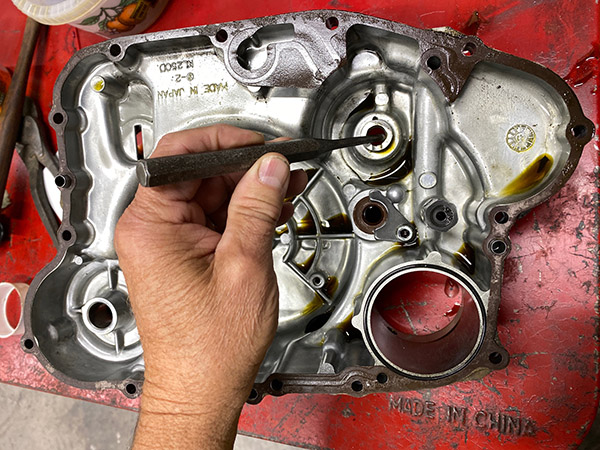

The next thing to go was the KLR250. When I had the Love Shack in Florida the KLR was the bike I left in the shed. Whenever we were in residence the KLR faithfully dragged me around central Florida. It wasn’t fast but I could hold 70mph on the highway if there wasn’t a headwind. The KLR sat as we moved junk across the country and then sat in the shed here at The Ranch for a few years. You know how that goes. The carb gummed up and it wouldn’t start.

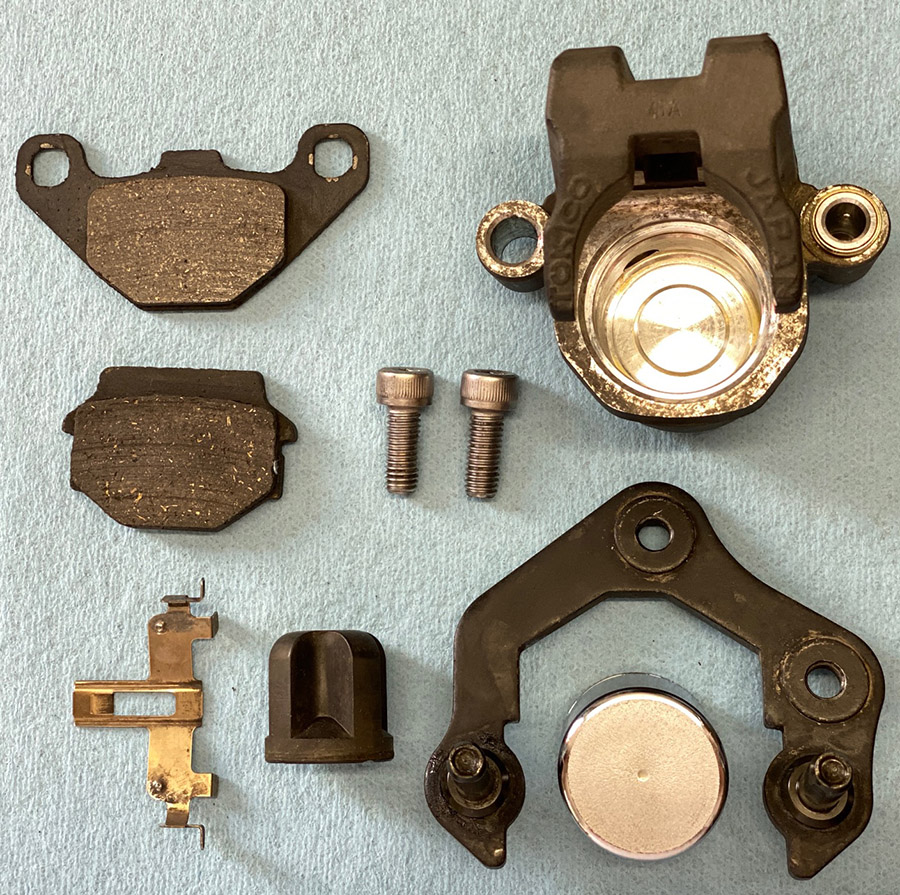

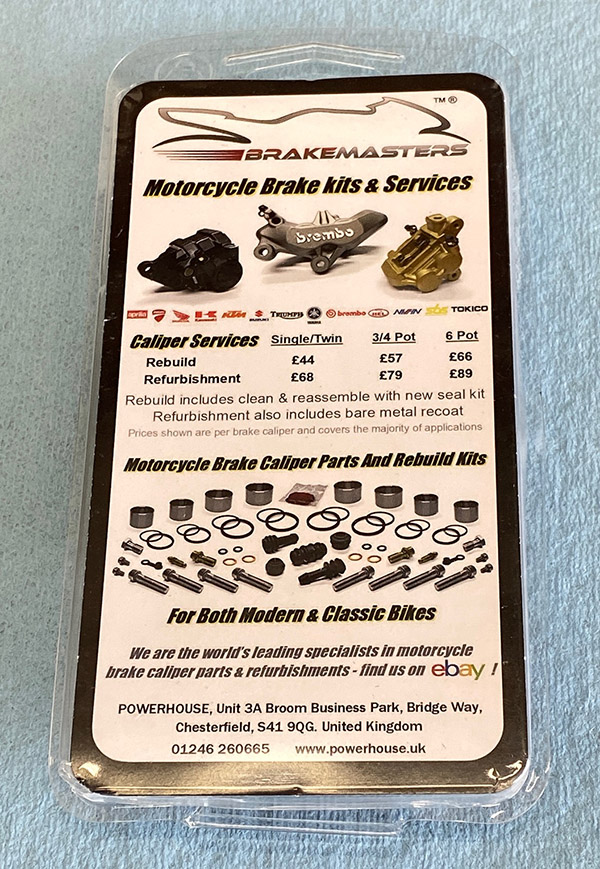

I decided to sell the bike but first I had to fix the front brake, fork seals and replace the front tire. After accomplishing those chores I wandered off to construction projects and the KLR languished. The final straw was when I skipped over the KLR250 to get the ZRX1100 running. I realized that the liquid-cooled 6-speed enduro bike had fallen completely off the to-do list.

Mike came to the rescue again and picked up the KLR250 for a cool 1000 dollars and dragged it back to his place. He has since replaced the stock constant velocity carb with a Mikuni clone off of Amazon and the bike starts and moves under its own power again. The new carb is jetted too rich so there’s a bit more fettling to be done but I won’t be doing it.

Having those two projects out of the way emboldened me to get rid of more junk. The Bomber is on the chopping block. I originally bought the Bomber for its running gear. I planned to put the Bomber’s small block Chevy and ½ ton running gear into Brumby (the Jeep). But the Bomber was so handy for hauling concrete the Jeep swap never took place. CT signed me up for a Lowes card and with the card Lowes will deliver anything to The Ranch for $20. This means no more concrete hauling and no need for the Bomber along with the Bomber’s tags and insurance.

I’ve got a few things to fix on the Bomber but I think I can get $1500 or so for the beast and that will be another project off my books and another year of my life back.

The trend line is clear to see: Stuff not getting used is going away. The 1975 Kawasaki 900 isn’t even safe now that the ZRX1100 is running. It has become too valuable and selling it would enable me to finish a few other projects, like my Honda 50 with a 140cc Lifan motor. Zed mostly sits because the purple Yamaha RD350 has taken over top spot in the vintage street bike category. I can only ride so many motorcycles at once.

You may say I’m getting lazy or maybe just old but I say I’m being realistic. There are still a few old motorcycles I’d like to own and clearing the decks is a time-honored tradition for normal people. Anyone need a Huffy beach cruiser with a 60cc two-stroke motor attached? It’s too fast downhill and too slow uphill. The thing is going to kill me if I don’t get rid of it.

More on the Gresh Resurrections!

Never miss an ExNotes blog: