I know what you’re thinking. You’re thinking I’ve been working on the KLR250 for forever. It seems that way to me also. Since the last KLR blog 325 years ago we have sold The Love Shack in Astor, Florida and the Widowmaker 250 no longer has a purpose in my life. I’m not one to store a good motorcycle and the KLR250 will make some newbie rider (or older experienced motorcyclist) a fine machine to learn the dark art of dirt riding.

It’s time for the KLR to go. I can’t keep all these bikes registered and insured, much less in operating condition. But before I let a new owner crash about on the KLR there are a few more things I need to fix.

Equipped with a worn out 21” front tire, a very popular size, I blew a few bucks on a new Dunlop semi-dirt tire and a new tube. These skinny 21” wheels are super easy to change tires on, it took like 20 minutes.

The Widowmaker’s fork seals were dribbling a decent flow of oil; in fact one tube only had a few ounces left inside. One fork leg came apart easily: Impact wrench on the bottom bolt and zing-zing it was apart. The other leg was more trouble. The recessed allen bolt just spun when I hit it with the impact.

I needed something to stop the inner damper rod from spinning the fork spring, which wasn’t offering enough resistance. Looking through my nut and bolt bins was futile. I found a spark plug was the closest to fitting the damper. I cut down the plug and removed the ceramic, then welded a length of all thread to the plug. With my new eye I could just make out the puddle. It was great, before I saw nothing but glare.

The damper rod retaining tool worked excellent and I was able to dismantle the other fork leg. After cleaning assembly was straightforward. A length of PVC pipe was used to press the new seals into the sliders. I didn’t have enough fork oil in one viscosity so I mixed 10 weight and 15 weight together. I figure I’m running 12.5 weight in the forks now.

I reassembled the front forks and all seemed done at the front. Next I installed a new battery just for the KLR250, no more sharing with the Husky and Z1. The battery has been sitting around a year or so but still had juice. I popped it into the KLR250, lowered the bike off the motorcycle jack and the thing started in about 7 kicks. These KLRs are tough cookies.

Thinking I was pretty much done, I took the bike on a road test. The carb might be a little clogged up as it’s either idling at 3000 RPM or dying. Once up to speed the bike ran as good as it ever has. Parking the bike on the brand new shed floor it was easy to notice coolant dripping from that small hole in the water pump housing. Rats, this is what I mean when I say I can’t keep them all running.

I ordered a new water pump seal and when it arrived I drained the Widowmaker’s coolant and removed the water pump cover and impeller. The seal is a spring-loaded ceramic type of deal and the spring part pulled off with little effort. That left the steel part still stuck in the engine.

If you’re lucky, sometimes you can thread a deck screw into the thin metal seal and pull the thing out with no problem. I wasn’t lucky and the seal kept looking worse the more I tried to remove it.

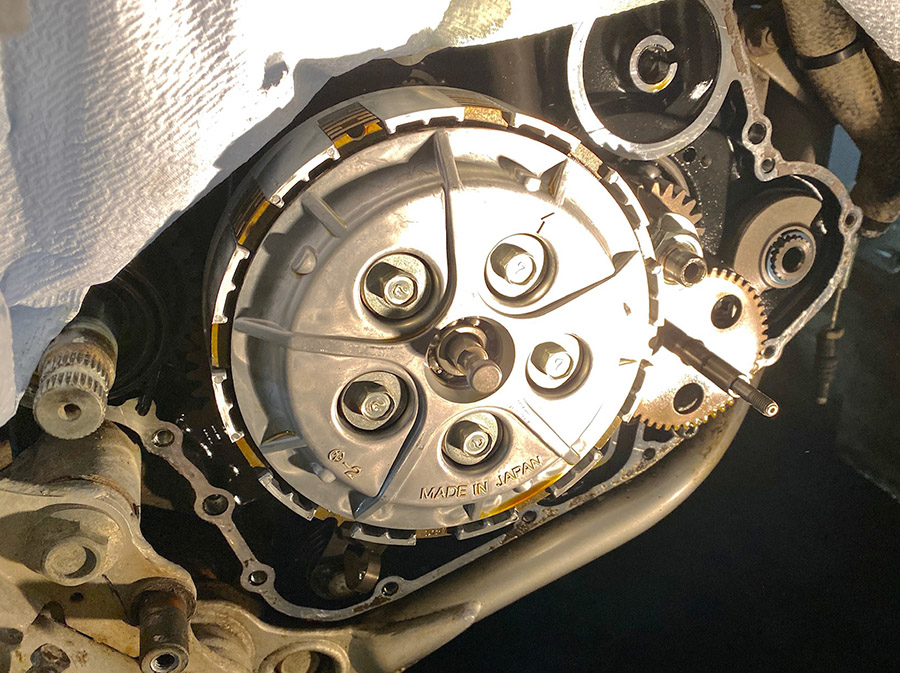

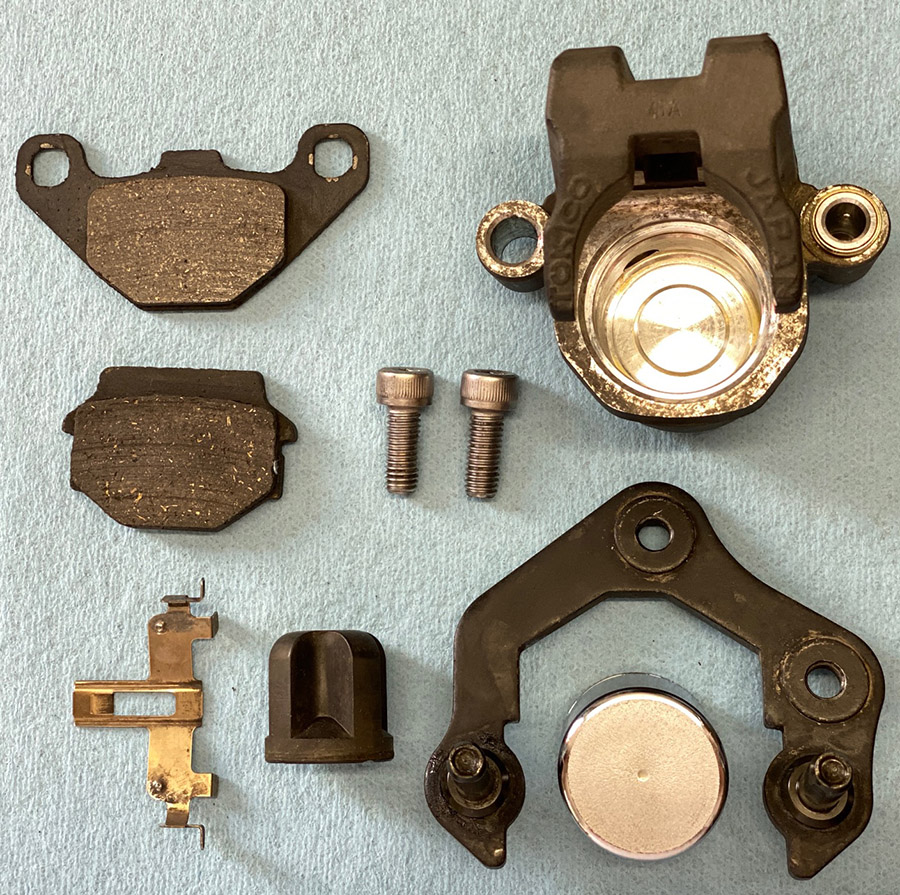

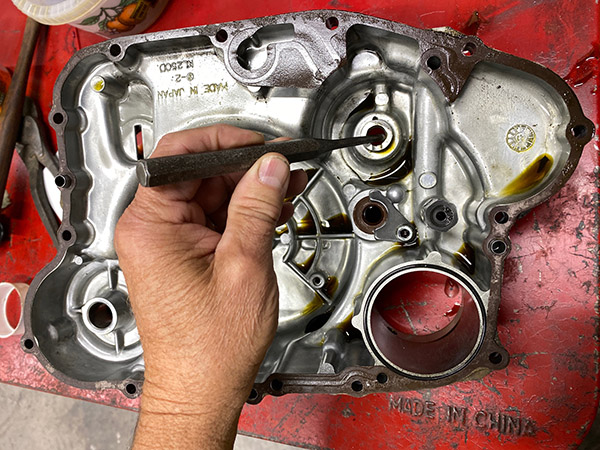

Finally I gave up and removed the right side engine cover to gain access to the seal from the other side. Removing the cover meant I had to remove the rear brake lever, foot peg and clutch cable. With the engine cover off it was a piece of cake to poke the seal out from the inside with a ¼” punch.

As you can see, I pretty much mangled the seal trying to save taking the engine cover off. For good measure I also destroyed the pump shaft oil seal in the process. I guess it needed changing also. Now I’ve got to look up a pump oil seal and a cover gasket for the Widowmaker. I think I’m going to clean the carburetor and see if I can’t make it run better low speed. Since I have to take the tank of to clean the carb I may as well adjust the valves. It’s super easy on the KLR250. And then it will be ready to sell.

More on the KLR and other Resurrections!

Never miss an ExNotes update…get your free subscription here.