By Joe Berk

I had a tough time choosing a title for this blog. I went with what you see above because it reminds me of one of my favorite Dad jokes…you know, the one about how you tell the difference between a crocodile and an alligator. If you don’t see it for a while, it’s a crocodile. If you see it later, well, then it’s a gator. The other choice might have been the old United Negro College Fund pitch: A Mine is a Terrible Thing to Waste. But if I went with that one I might be called a racist, which seems to be the default response these days anytime anyone disagrees with anyone else about anything.

Gresh likes hearing my war stories. Not combat stories, but stories about the defense industry. I never thought they were all that interesting, but Gresh is easily entertained and he’s a good traveling buddy, so I indulge him on occasion. Real war stories…you know how you can tell them from fairy tales? A fairy tale starts out with “once upon a time.” A war story starts out with “this is no shit, you guys…”

Don’t forget to click on the popup ads…it’s how we get paid and how we keep the blog alive.

So, this is a “no shit” story. It sounds incredible, but it’s all true. I was an engineer at Aerojet Ordnance, and I made my bones analyzing cluster bomb failures. They tell me I’m pretty good at it (I wrote a book about failure analysis, I still teach industry and gubmint guys how to analyze complex systems failures, and I sometimes work as an expert witness in this area). It pays the rent and then some.

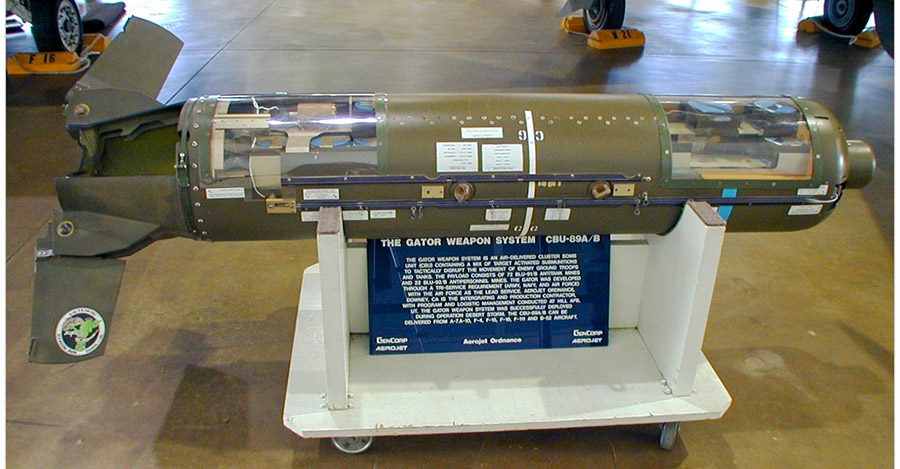

So this deal was on the Gator mine system, which was a real camel (you know, a horse designed by a committee). The Gator mine system was a Tri-Service program (three services…the Army, the Navy, and the Air Force). It was officially known as the CBU-89/B cluster munition (CBU stands for Cluster Bomb Unit). The way it worked is instead of having to go out and place the mines manually, an airplane could fly in and drop a couple of these things, the bombs would open on the way down and dispense their mines (each cluster bomb contained 94 mines), the mines would arm, and voila, you had a minefield. Just like that.

It sounds cool, but the Gator was a 20-year-old turkey that couldn’t pass the first article test (you had to build two complete systems and the Air Force would drop them…if the mines worked at a satisfactory level, you could start production). The UNCF slogan notwithstanding, the folks who had tried to take this Tri-Service camel and build it to the government’s design wasted a lot of mines. In 20 years, several defense contractors had taken Gator production contracts, and every one of them failed the first article flight test. When my boss’s boss decided we would bid it at Aerojet, I knew two things: We, too, would fail the first article flight test, and it would end up in my lap. I was right on both counts. We built the flight test units per the government design and just like every one else, we failed with a disappointing 50% mine function rate. And I got the call to investigate why.

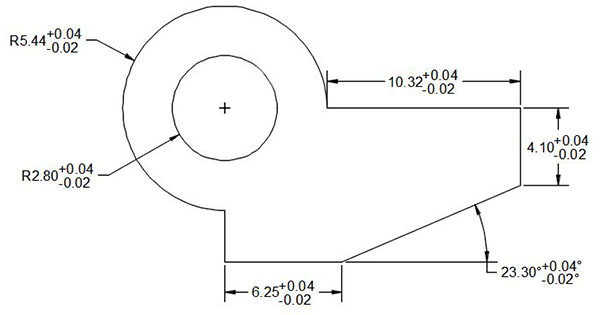

So, let’s back up a couple of centuries. You know, we in the US get a lot of credit for pioneering mass production. Rightly so, I think, but most folks are ignorant about what made it possible. Nope, it wasn’t Henry Ford and his Model T assembly line. It was something far more subtle, and that’s the concept of parts interchangeability. Until parts interchangeability came along (which happened about a hundred years before old Henry did his thing), you couldn’t mass produce anything. And to make parts interchangeable, you had to have two numbers for every part dimension: The nominal dimension, and a tolerance around that dimension. When we say we have a 19-inch wheel, for example, that’s the nominal dimension. There’s also a ± tolerance (that’s read plus or minus) associated with that 19-inch dimension. If the wheel diameter tolerance was ±0.005 inches, the wheel might be anywhere from 18.995 to 19.005 inches. Some tolerances are a simple ± number, others are a + something and a – something if the tolerance band is not uniform (like you see in the drawing below). But everything has a tolerance because you can’t always make parts exactly to the nominal dimension.

Where companies get sloppy is they do a lousy job assigning tolerances to nominal dimensions, and they do an even worse job analyzing the effects of the tolerances when parts are built at the tolerance extremes. Analyzing these effects is called tolerance analysis. Surprisingly, most engineering schools don’t teach it, and perhaps not so surprisingly, most companies don’t do it. All this has been a very good thing for me, because I get to make a lot of money analyzing the failures this kind of engineering negligence causes. In fact, the cover photo on my failure analysis book is an x-ray of an aircraft emergency egress system that failed because of negligent tolerancing (which killed two Navy pilots when their aircraft caught fire).

I don’t think people consciously think about this and decide they don’t need to do tolerance analysis. I think they don’t do it because it is expensive and in many cases their engineers do not have the necessary skills. At least, they don’t do it initially. In production, when they have failures some companies are smart enough to return to the tolerancing issue. That’s when they do the tolerance analysis they should have done during the design phase, and they find they have tolerance accumulations that can cause a problem.

Anyway, back to the Gator mine system. The Gator system had a dispenser (a canister) designed by the Air Force, the mines were designed by the Army, and the system had an interface kit designed by the Navy. Why they did it this way, I have no idea. It was about as dumb an approach for a development program as I have ever seen. Your tax dollars at work, I guess.

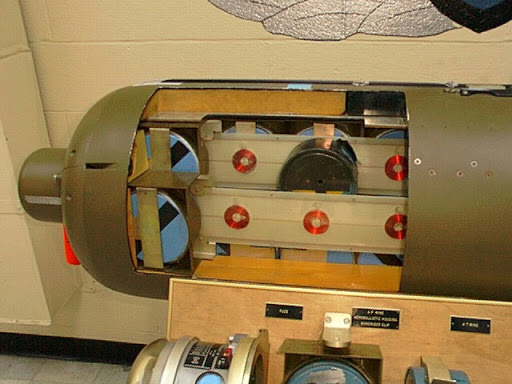

The Navy’s Gator interface kit positioned the mines within the dispenser and sent an electronic pulse from the dispenser to the mines when it was time to start the mine arming sequence. This signal went from coils in the interface kit to matching coils in each mine (there was no direct connection; the electric pulse passed from the interface kit coils to the mine coils). You can see these coils in the photo below (they are the copper things).

In our first article flight test at Eglin Air Force Base, only about 50% of the mines worked. That was weird, because when we tested the mines one at a time, they always worked. I had a pretty good feeling that the mines weren’t getting the arming signal. The Army liked that concept a lot (they had design responsibility for the mines), but the Air Force and the Navy were eyeing me the way a chicken might view Colonel Sanders.

I started asking questions about the tolerancing in the Navy’s part of the design, because I thought if the coils were not centered directly adjacent to the matching coils in each mine, the arming signal wouldn’t make it to the mine. The Navy, you see, had the responsibility for the stuffing that held the mines in place and for the coils that brought the arming signal to the mines.

At a big meeting with the engineering high rollers from all three services, I floated this idea of coil misalignment due to tolerance accumulation. The Navy guy basically went berserk and told me it could never happen. His reaction was so extreme I knew I had to be on to something (in a Shakespearian methinks the lady doth protest too much sort of way). At this point, both the Army and Air Force guys were smiling. The Navy guy was staring daggers at me. You could almost see smoke coming out his ears. He was a worm, I was the hook, and we were going fishing. And we both knew it.

I asked the Navy engineer directly how much misalignment would prevent signal transmission, he kept telling me it couldn’t happen, and I kept pressing for a number: How much coil misalignment would it take? Finally, the Navy dude told me there would have to be at least a quarter of an inch misalignment between the Navy coils and those in the mine. I don’t think he really knew, but he was throwing out a number to make it look like he did. At that point, I was pretty sure I had him. I looked at my engineering design manager and he left the room. Why? To do a tolerance analysis, of course. Ten minutes later he was back with the numbers that showed the Navy’s interface kit tolerances could allow way more than a quarter inch of misalignment.

When I shared that with the guys in our Tri-Service camel committee, the Navy guy visibly deflated. His 20-year secret was out. The Army and the Air Force loved it (they both hated the Navy, and they really hated the Navy engineer).

We tightened the tolerances in our production and built two more cluster bombs. I was at the load plant to oversee the load, assemble, and pack operation, and when we flight tested my two cluster bombs with live drops from an F-16 we had a 100% mine function rate (which had never been achieved before). That allowed us to go into production and we made a ton of money on the Gator program. I’m guessing that Navy weasel still hates me.

It’s hard to believe this kind of stuff goes on, but it does. I’ve got lots of stories with similar tolerance-induced recurring failures, and maybe I’ll share another one or two here at some point. Ask me about the Apache main rotor blade failures sometime…that’s another good one and I’ll post a blog about it in the next week or so.

Stay tuned, my friends.

Never miss an ExNotes blog: