By Joe Gresh

Harbor Freight’s economy brand, Chicago Electric, has been much improved over the years. Back in the 1990s you were lucky to get a few months use out of a CE tool before it burned up. Of course, what did you expect from a 10-inch circular saw that cost 15 dollars? They were sort of one-use tools, bought for a particular job then tossed in the trash after the job was done. This early crappiness has tainted the Chicago Electric brand and there might still be a few dud CE products out there.

I’ve had pretty good luck with more recent Chicago Electric stuff. Their paddle-switch 4-inch grinder has lasted 10 years for me and is still going strong. I have a Chicago Electric sawsall that is pretty old and it has held up well. You no longer get smoke pouring out of a Chicago Electric tool the first time you plug it in.

This Chicago Electric Double Cut saw is marked down on clearance at 44 dollars. In Harbor Freight land a clearance item usually means the tool is being discontinued and when they are out they are out. I had to get my local HF technician go into the back of the store and rummage around to find one. You may have to visit several stores to find one. Clearance tools are usually superseded by a similar tool with a possible upgrade in quality or just bold new graphics so if you can’t find a Double Cut saw just wait a bit and another one with a different part number will appear. Although, it won’t be $44.

I’m impressed with the improved quality of the CE Double Cut saw. The castings, both metal and plastic look well made and finished nicely. This saw has a bit of heft so at least there is some copper and steel in the thing. The saw comes mostly assembled, you only need to put the grab handle on and feed a lube stick into the nifty feed hole provided. Like most CE power tools the cord is stiff and plasticky I guess it’s better than the SO type of cord with the easily damaged jacket. The saw comes with a nice little wrench for changing the two (included, carbide-tipped) blades.

Ergonomically, The saw has some issues for me. The power switch is an odd, push down and forward, deal that takes some getting used to. You have to hold the switch on, this puts your hand close to the front of the saw and your other hand is holding the grip nearby. I would move the switch aft on the tool to give better hand separation and thus more steering control. By necessity, the saw blades are almost completely shielded which makes seeing your cut line impossible. There is a V- notch in the front of the blade housing that gives an Idea of where the cut will be. If you want a precision cut you’ll need to rig up a fence. By the way, don’t even think of removing the shields as the Double Cut puts out metal particles when it plows through steel. Wear safety goggles!

What makes the Double Cut somewhat unique is the two, counter-rotating blades. This arraignment cancels out any kickback or climbing out of the cut. Cutting round stock is a breeze, as the material doesn’t try to spin when the blade makes contact. The saw feels wonderfully neutral in action and not the least bit scary cutting steel. The saw is useable on most any material: steel, aluminum, and wood. There is a blade lube feature for use on stickier metals like aluminum or sappy woods. I bought the saw for metal.

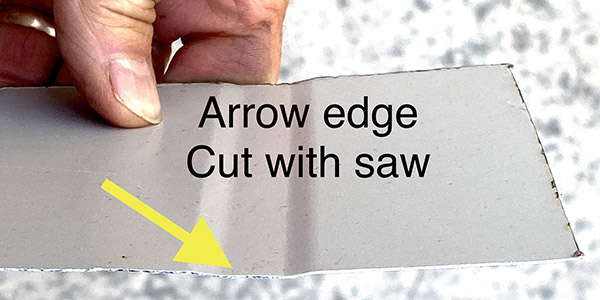

I’ve used the saw on 1/8” mild steel and it cut like a hot knife through I Can’t Believe It’s Not Butter. Again, there’s a fine mist of metal particles generated while cutting so wear those goggles. The finished cut is clean with no sharp flashing like with a 4-inch abrasive cut off wheel. On sheet metal roofing the saw cuts as fast as you can push leaving a clean, square edge to slice your finger on when you hoist the panel onto the roof. If you do metal roofs you need this saw.

I probably should take the saw apart and grease the internals but the thing might fly apart on disassembly so I’ll use it as is for the foreseeable future. The depth of cut is only 1-1/4’ but really, if you tried cutting steel that thick you’d probably burn up the saw. Blade depth adjustment is in your hands as there is no hinged foot to set the blade. I don’t know how long the blades will last cutting steel and if the saw is truly discontinued you might want to stock up on replacement blades available at your local Harbor Freight store.

The verdict is in and I pronounce the Double Cut a fine deal at only 44 dollars. If you work with thin-ish metals, say 1/8” to sheet metal this could be your saw. For complex cuts I still use the 4” grinder with an abrasive, metal cutting blade because the line of sight is better, you can see exactly where the blade is. Harbor Freight isn’t the only company that makes this type of saw. Other brands are available, here’s one online at Amazon and the saw looks about the same.

Never miss an ExNotes blog:

Thanks for the review of double cut saw.

I’ll never ever need one but I learned a lot about a new (to me) tool from a man who knows how to select relevant information and present it logically.

Thanks, Carl

A fine review. Though there isn’t anything wrong with a good hacksaw.

I agree. I take pride in my ability in handling a hacksaw. My weapon of choice- a Victor Star. I’d go up against Alan Millyard any day.

I never heard of such a thing. Double cut? Now I know.

I appreciate your review. I never gave a thought to a double-cut saw because I have never seen one in action or seen a review. Faster than a nibbler for sure. Unfortunately my Harbor Freight is sold out, and it’s a several hour drive to the closest store that has one.

Great info here Joe.

I’m wondering what magicery makes the saw turn the 2 blades in opposite directions?

Never seen one so totally new idea to me, thanks Joe

Joe points out that some CE tools were considered adequate and disposable. I would agree.

Over time, the power tools have come a long way.

We bought some Hercules impact wrenches and they have been such force multipliers making a new Durango front end much easier task than anticipated.

I would add that if a guy is planning a project, needing tools, HF is now setup pretty much as a one stop shop if going to a local store. Someone put some thinking into evolving product lines and breadth of offerings.

Recently, I have personally spoken to two gals who both admitted they actually enjoy going to HF stores for home diy tools.

The multi tool blades they sell buzz through fiberglass with minimal dust and clean line. And they’re quick to buy.

I’ve been chided over the made in C*** thing, but I like to pour gas on a fire, and then point to my RX3 n RX4 while not so casually pointing out the campfire tube….

Geez Gresh, even the KLR guys are moving from milk crates to HF Apache boxes nowadays haha!

Real milk crates? I prefer the steel ones of yore. Made in usa. Not fake wallmart made in China plastic ones.