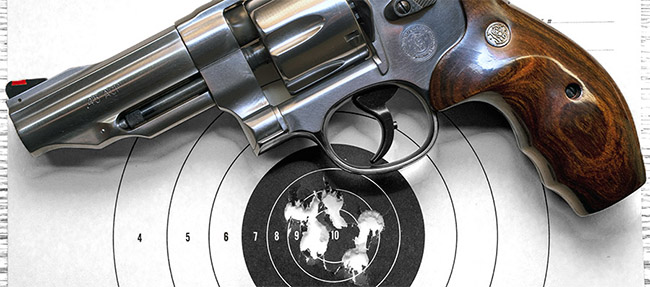

The revolver you see in the blog today is a rare animal, one of 650 customized by New York City’s John Jovino Gun Shop. I guess the best way to start this post is with the John Jovino story. The Jovino Gun Shop is no longer in business, having fallen victim to the Covid 19 pandemic, but until then it was the oldest gun shop continuously in business in the entire country. John Jovino opened the store in 1911; he sold it to the Imperato family in the 1920s (the Imperatos are the folks who started and now operate Henry Firearms). Jovino’s was famous and it’s been in more than a few movies (and even in my favorite TV show, Law and Order).

Back in the 1980’s, Jovino’s built custom guns. Their primary clients were the NYPD and other police departments, as well as individual police officers, so many of the Jovino customs tended to be duty-oriented carry weapons. The one you see here is no exception. Jovino’s started with 6.5-inch-barreled Model 25 Smiths chambered for the .45 ACP cartridge and they turned them into 2.5-inch snubnosed revolvers. The conversion from a stock Smith and Wesson Model 25 to a Jovino snubbie, though, was not just a simple chop job. Here’s what the wizards at Jovino did to these guns:

-

-

- Shortened the factory barrel to 2.5 inches.

- Installed a crane lock to replace the ejector rod lock.

- Relocated the red ramp front sight.

- Rounded the butt to the S&W K frame round butt configuration.

- Tuned the double and single action trigger.

- Radiused the hammer spur (you can see it in the photos).

- Polished the trigger face (you can see that in the big photo at the top of this blog).

- Fitted Pachmayr rubber grips.

- Reblued the cut barrel (the new bluing is actually a bit darker and more polished than the stock bluing).

-

As you probably already know (and you certainly know if you follow the ExhaustNotes blog), the 1917 platform Smith and Wesson and Colt revolvers can fire .45 ACP ammo if the cartridges are mounted in clips, or they can fire .45 AutoRim ammo. .45 AutoRim ammo is essentially the .45 ACP cartridge with a rim. For this test series, I used reloaded .45 AutoRim ammo. It’s the ammo you see in the photo below.

The original grips that came with the Jovino Model 25 snubbie were Pachmayrs, and they probably make more sense (more on that at the end of this blog). I didn’t care for the appearance and for reasons it would take a therapist to explain, I wanted ivory grips (I think it has something to do with watching Patton too many times). I settled for fake ivory, which provided the look I wanted without the cost. Don’t tell the General.

When the new grips arrived, I liked the S&W escutcheons and I liked the look, but I didn’t like the fit. I didn’t realize what I had in the Jovino and the extent of the customization that went into these guns. I ordered grips for an N-frame round butt Smith and Wesson, but they stood a bit proud on the revolver’s grip frame (the back strap). That’s because the Jovino customs reworked the frame from a square N-frame grip profile to a Smith and Wesson round butt K-frame profile, but I’m told the K-frame grips won’t match exactly, either. I bought the larger N-frame grips figuring I could take grip material off, but I couldn’t put it back on. I didn’t dare attempt to sand the grips on the gun, so I very gently went to work on them with sandpaper off the gun, repeatedly installing and removing the grips to take off just enough material to get a good grip-to-frame match. When I was just about there, I found that by stepping down to 400, then 600, and then 800 grit sandpaper, I could match the polished look on the rest of the grip. I was pleased with the result.

I tested three .45 AutoRim loads:

-

-

- A 200-grain Speer swaged semi-wadcutter bullet loaded with 4.2 grains of Bullseye.

- A 200-grain Precision Cast semi-wadcutter bullet loaded with 6.0 grains of Unique.

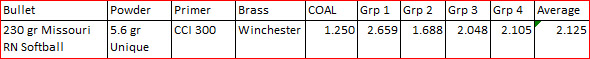

- A 233-grain Missouri K-Ball cast roundnose bullet loaded with 5.6 grains of Unique.

-

I had already tested my Jovino revolver for accuracy at longer distances a few years ago; this test was to be different. Like the .38 Special Model 60 accuracy tests we wrote about a couple of days ago, I set up a few “Betty and the Zombie” targets at 7 yards and I fired double action as quickly as I could. I’m told the typical hostage rescue zombie gunfight occurs at 7 yards, so I wanted to get a feel how I would do in these encounters. You know, so I’d be ready.

What was surprising to me was just how incredibly smooth the double action trigger was on the Jovino. In a word, it’s amazing. Shooting double action was fun. The slick trigger and the Model 25 Jovino’s red ramp and white outline sights seem to glue the front sight to the zombie’s left eye, until that part of the zombie disappeared and I was shooting at a hole. These guns are impressive.

The 200-grain semiwadcutter with 4.2 grains of Bulleye was a very pleasant load (for me, not the zombie) with modest recoil. The 233-grain K-Ball Missouri load was a much more emphatic load. That one pounded me around a bit more, but it still hung in there on the zombie. All of the loads shot essentially to point of aim. Each of the targets below were hit by five full cylinders of .45 ammunition, or 30 rounds apiece. There was not a single miss among all 90 rounds.

So what’s the bottom line to all of this? The Jovino .45 ACP revolver is accurate, it has a superb trigger, and it is just plain fun to shoot. That last load was a bit much. The 233-grain K-Ball Missouri looks pretty much like their 230-grain roundnose, but the difference in recoil is both perceptible and significant. You can go quite a bit hotter with this load, but I won’t. When I finished shooting, I was surprised to see I had done a bit of damage to my thumb. I think it happened on the last round or two because there’s no powder residue where the skin tore away, and it happened because the faux ivory grips have a bit of a corner to them. The rubber Pachmayr grips wouldn’t have done this, but they don’t look as cool as the grips the Jovino wears in these photos. The gun doesn’t do this firing single action, but I guess my hand rode up a bit firing double action. Sometimes these things happen when you take on the odd zombie or two.

The Jovino Model 25 is probably the finest and smoothest revolver I’ve ever shot. It’s a keeper.

Why you should click on those popup ads!

Never miss an ExhaustNotes blog!

More Tales of the Gun!

More .45 ACP revolver stories….check these out!