I posted a series of blogs on my Ruger No. 1 in .257 Weatherby and the loads I was developing for it a few months ago, and I told you about the stock cracking on my rifle. That held things up for a while.

Ruger Customer Service

I was disappointed about the stock fracture, but the wizards at Ruger did a good job in selecting a piece of wood of comparable quality, figure, and tone. I also asked Ruger to return the defective stock to me after they installed the new one, and they did. And they didn’t charge me anything to put a new stock on the rifle (it was a warranty repair). Ruger sent photos of three stocks they had selected that were a good match for the forearm, and they allowed me to pick the one I wanted. More good news is that I believe the stocked crack can be repaired. I’m going to do that and maybe put it back on this rifle. Or maybe I’ll just have it as a spare.

Tang Relief

I believe the reason the original stock cracked is that the wood around the receiver tang had not been properly fitted (there should be a little clearance to prevent the tang from acting like a wedge to split the wood). I asked Ruger to make sure the new stock had some clearance behind the tang, and they did. They actually went a little overboard in my opinion, but that’s preferable to having no relief.

More good news is that I now have a load that reaches into the upper stratosphere of what the .257 Weatherby cartridge can do, and it does so with high velocity and great accuracy.

The New Ruger No. 1 Stock

First, allow me to show you the new lumber on the Ruger No. 1:

Here are a couple more shots to show the new stock, one in the gun rack and another on my workbench when I was cleaning the rifle:

A Mississippi Dave .257 Weatherby Load

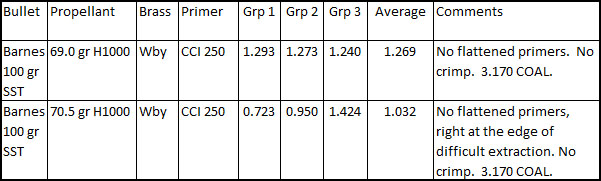

I’d like to take credit for discovering the load on my own, but I can’t do that. My good buddy Mississippi Dave, who knows more about the .257 Weatherby cartridge than anybody I know, turned me on to Barnes solid bullets and H1000 propellant powder as the keys to success with this cartridge, and he was spot on in his guidance. Here are my results, all at 100 yards:

Those are great results, and 70.5 grains of H1000 is the load I am going to use with the Barnes bullets. I think I could have done even better, but conditions were less than ideal when I was shooting that day. There were a lot of guys on the range the day I was out there, including a couple of Rambo wannabees on either side of me with assault rifles and muzzle brakes shooting rapid fire. I know that’s what caused that third group with 70.5 grains of H1000 to open up to over an inch. I think the No. 1 could be a half-minute-of-angle rifle with this load. And this load in my rifle (the Ruger has a 28-inch barrel, 2 inches longer than normal) is probably attaining velocities well over 3700 feet per second. That’s smoking.

One quick additional comment on the above loads: These are loads that work in my rifle. Your mileage may vary. Always consult a reloading manual when you develop a load, and always start at the bottom of the propellant range and slowly work up. Barnes publishes their recommended reloading data, and you can go to their website to download that information.

Barnes Bullets

The high velocities mentioned above are only possible with Barnes’ solid copper bullets. Jacketed bullets (lead core bullets shrouded in a copper jacket, which is normally how bullets are constructed) would break up in flight at these higher velocities, and for me, they did (see the earlier .257 Weatherby blogs).

.257 Weatherby Lessons Learned

I’ve learned a lot, with help from Mississippi Dave, about reloading the .257 Weatherby cartridge. You have to use solids (the monolithic Barnes bullets) to realize the full velocity potential of the .257 Weatherby. The .257 Roy can be extremely accurate, and at its upper-range velocities, higher velocities means more accuracy. Cup and core (conventional jacketed) bullets will work in the .257 Weatherby, but only at lower velocities, and if you’re going to do that, you’re not really using the .257 Roy the way it is intended to be used. Bore cleanliness is critical on these rifles, and because of the huge powder charges and high projectile velocities, the bore fouls quickly. When you reload for this cartridge, you not only need to full-length resize the cartridge case, you need to go in another 90 degrees on the resizing die after it contacts the shell holder in order to get the round to chamber. The best powders for this cartridge are the slow burning ones. H1000, in particular, works well in my rifle.

Earlier .257 Weatherby Blog Posts

The .257 Weatherby sage has been a long one but it is a story with a happy ending. If you’d like to read our earlier blogs on this magnificent cartridge, here they are:

A Real Hot Tamale

Reloading the .257 Weatherby

Taking Stock of Things

The .257 Weatherby Saga Continues

More Cool Reloading and Gun Stuff

If you enjoyed this blog and you want to see more, you can read our other Tales of the Gun stories here. And if you don’t want to miss anything from us, sign up for our automatic email blog notifications here: