By Joe Berk

I had a good morning at the West End Gun Club recently. I shot the 6.5 Creedmoor rifles, a .223 Browning Micro Medallion, and Jim Gardner’s powder-coated cast bullets in a 7mm Remington Magnum Ruger No. 1. I might get around to writing about the other rifles, but for today, the focus is on the 7mm Magnum No. 1 and powder-coated cast bullets. I’ve written about shooting 7mm cast bullets in the No. 1 before; those results were mediocre and the barrel leaded enough after five rounds that accuracy went to hell (I had to clean the bore with a bristle brush after ever group). The powder coating Jim applies makes a difference. The Gardner powder-coated bullets did not lead the barrel (at all) and the results were good. I think I’ve finally found a decent cast bullet load for this rifle.

I have had a lot of difficulty making this rifle perform with the powder-coated cast bullets. It was apparent they weren’t leading like my other cast bullets had, but they weren’t very accurate. Neck sizing only, which often improves accuracy, compounded the felony. It didn’t work well at all, mostly because I couldn’t chamber most of the rounds (even though they had been fired in the same 7mm Magnum Ruger No. 1 rifle). I also tried seating the bullets further out, but one got stuck when I chambered a round and when I removed it, the bullet came out of the case and Trail Boss propellant spilled all over the guts of the rifle. That led to it not extracting, so I had to disassemble the action and clean everything. I also tried crimping, but those rounds weren’t any better.

This morning’s batch were full length resized, not trimmed, and not crimped. I flared the case mouth just a tiny bit to let the Gardner powder -coated bullets enter without shaving any of the powder coating or the lead, and I seated them a little deeper so that they did not contact the rifling. When I seated the bullets this time, they expanded the case mouth just enough to eliminate the flare. This batch chambered easily.

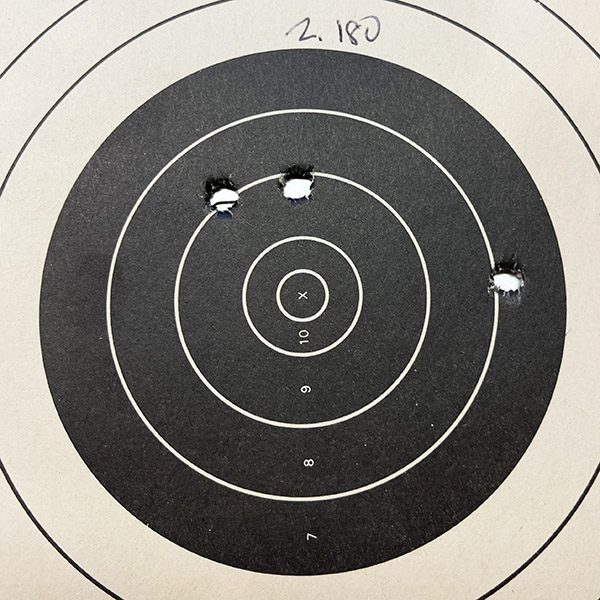

I had one round left over from a previous batch, and I fired it first (all shots are and groups discussed here were 50 yards from a rest). That one round was left over because it wouldn’t chamber the previous time I had the rifle out because the case had deformed slightly when I overcrimped it. I had to run that round through the full length resizer (bullet and all, with the decapping pin removed) so it would chamber. It was my first shot of the day and it shot a little to the right (as you can see above). That first group was the biggest group of the morning.

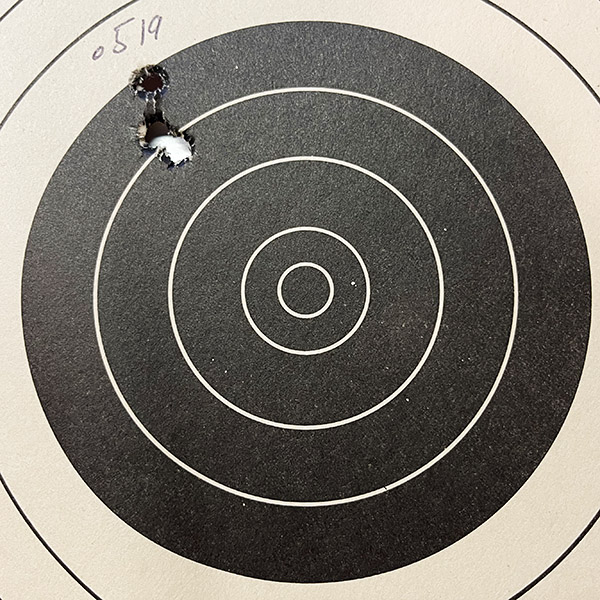

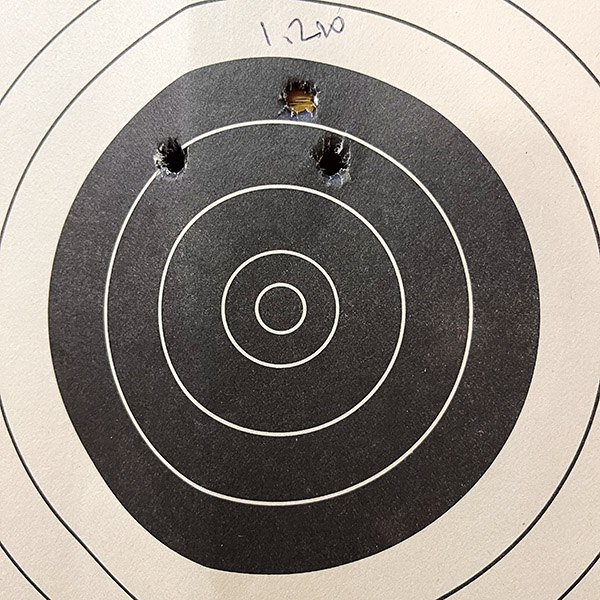

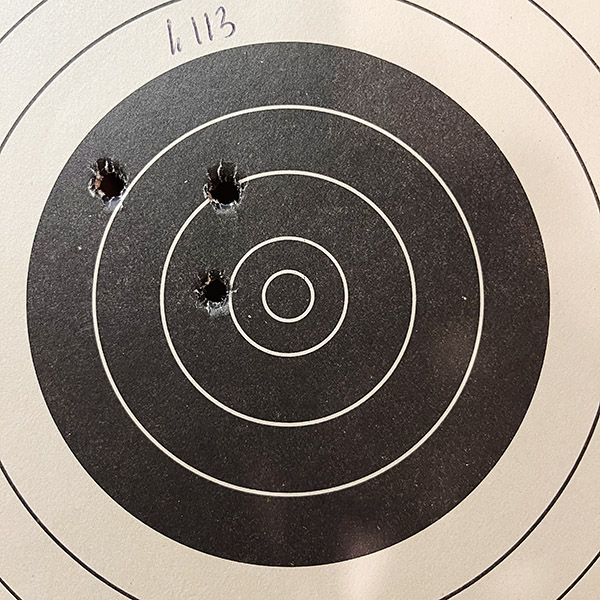

I then shot four more groups, and all the rest grouped nicely.

At 50 yards, these aren’t what I would call amazing groups, but they are getting better and that one half-inch group shows promise. I bought a thousand of the Gardner powder coated bullets, so it’s nice to know I can get then to work. The powder charge was 18 grains of Trail Boss, dispensed (not individually measured). I may go out to a hundred yards on the next outing to see how they perform. But where they are, I’d feel comfortable chasing rabbits with them.

The tricks to this load were full length resizing, no crimp, very slight case mouth flare, 18.0 grains of Trail Boss, Winchester large rifle primers, Remington brass, and a cartridge overall length of 3.127 inches. I’m going to try this load again. The brass is in the tumbler now.

I’m pleased with the Gardner powder-coated bullets, and if you’re interested in purchasing some, you might take a look at Jim’s website.

Never miss an ExNotes blog:

Does the powder coating reduce bullet/barrel friction and therefore increase muzzle velocity? Kind of like a sabot?

Bob, I don’t have a chronograph so I can’t say yes based on my experience. I suspect that they do. The Gardner powder-coated bullets are the only ones I’ve used in a rifle that had the powder coating hold up. The others I’ve tried leaded the barrels; these do not. They are slippery to the touch, so I believe they reduce bore friction significantly.

Thanks for commenting.