I’ve been on a tear the last few weeks, playing with the Mk V 300 Weatherby and developing loads for it. I developed loads with cast bullets and with jacketed bullets, and at reduced-load levels and at factory ammo levels.

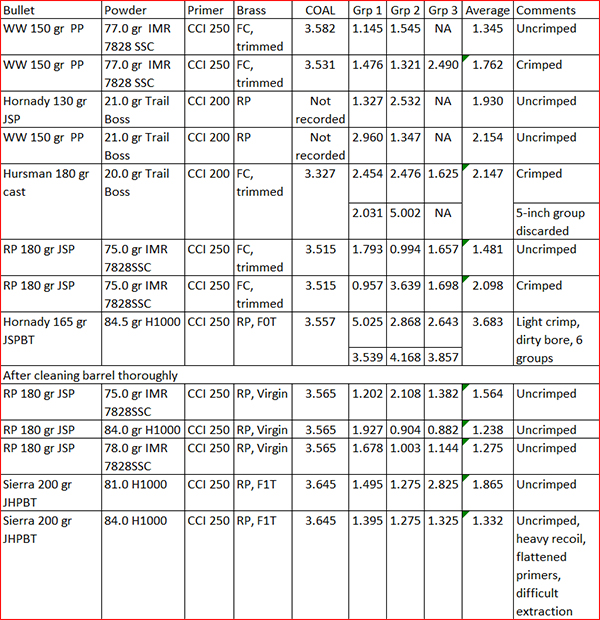

The Internet weenies advise going hotter with this cartridge to get better accuracy, but I don’t want more accuracy that badly (don’t get me wrong; I like accuracy, but not at the expense of this kind of recoil). The recoil with this cartridge is severe. I shot some sub-minute-of-angle groups with the 180 grain Remington jacketed softpoint bullets. I also had a few larger groups, but I’m chalking that up to the wind and me still being a bit recoil sensitive. For me, it’s close enough to call it done.

All groups presented here were at 100 yards from my Mk V Weatherby. It has a walnut stock and a 26-inch barrel. I bought this rifle about 10 years ago but I had not shot it much until recently. I have a 4×16 Weaver on this rifle and all groups were with the scope at 16X. The scope is no longer available, but it is a good one.

This Mk V initially had a terrible trigger. It was creepy and gritty, and it was so bad it surprised me. I was thinking about spending another $200 on a Timney trigger and then a funny thing happened: The trigger suddenly and spontaneously improved. It’s about a three-pound trigger now with zero creep. Don’t ask me how or why. Maybe there was some grit in the trigger, or maybe there was a burr somewhere in the mechanism. Whatever it was, it’s gone.

I now use a Caldwell shoulder pad for the full bore stuff. It helps tremendously with recoil, but it is probably degrading my shooting position because of the unnatural stretch to get a good scope picture and cheek weld. Even with that pad, though, I still get kissed by the scope on occasion. The rifle likes to let me know who’s the boss.

Cast bullets are okay for light loads and practicing, but to keep the groups below 3 inches, I had to use a bore brush between every group. If I didn’t bore brush it every three shots, the groups opened up. If I use a bore brush and run it through the barrel three or four times after each group I can keep my shots in the black.

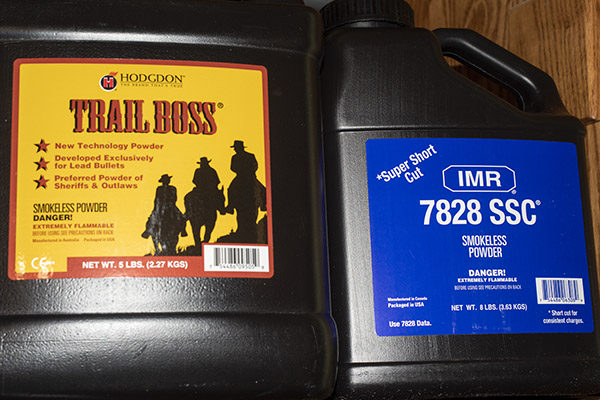

After calling Hodgdon to make sure I wouldn’t blow myself up, I tried a few jacketed loads with 130 grain Hornady and 150 grain Winchester bullets and Trail Boss powder. They grouped okay. The jacketed bullets with Trail Boss were more accurate than the cast bullets, but not as good as the full bore stuff. It’s good to know, but I’ll reserve the Trail Boss for cast loads.

I shot neck sized brass with the Trail Boss cast and jacketed loads because the Trail Boss loads don’t expand the case very much and it’s easier to reload if I neck size only. I don’t have to lube the cases and it goes a lot faster.

The Trail Boss sweet spot with cast bullets is 20.0 grains. That’s near the bottom of the charge range. I went down to 19.5 grains and there was no improvement in group size. I went above 20.0 grains and the groups opened up. I’m a quick study. 20.0 grains. Got it.

I tried neck sizing only (instead of full length resizing) with full bore loads and I found that was not the way to go. I had a lot of cases that wouldn’t extract when I shot neck sized only full bore loads, and then I found when I neck sized a case it stuck it in the chamber even without firing (it was difficult to extract). Full bore loads have to be full length resized in my 300 Weatherby (with an extra quarter turn on the sizing die after it touches the shell holder for this rifle; that’s a trick a tech rep at Sierra turned me on to). The cases expand too much if you neck size only after firing full bore loads.

With cast bullets, crimping the bullet is necessary for better accuracy. Not crimping opened up the groups substantially. Crimping brought them back down. But that’s only with cast bullets. For jacketed bullets, the rifle doesn’t care if you crimp them or not. There’s no accuracy gains to be had with crimping jacketed bullets in my rifle.

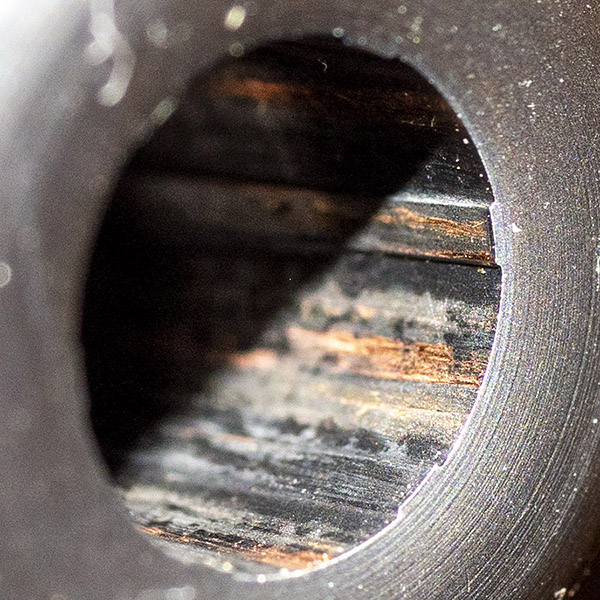

Keeping the bore clean makes a difference (duh), and you need to get up close to make sure the bore is clean. Simply judging cleanliness by the patch coming out clean isn’t good enough. After my patches were coming out clean, I took a photo of the muzzle. I looked at it on my computer and I was shocked. Before examining the photo, I thought this was a clean barrel:

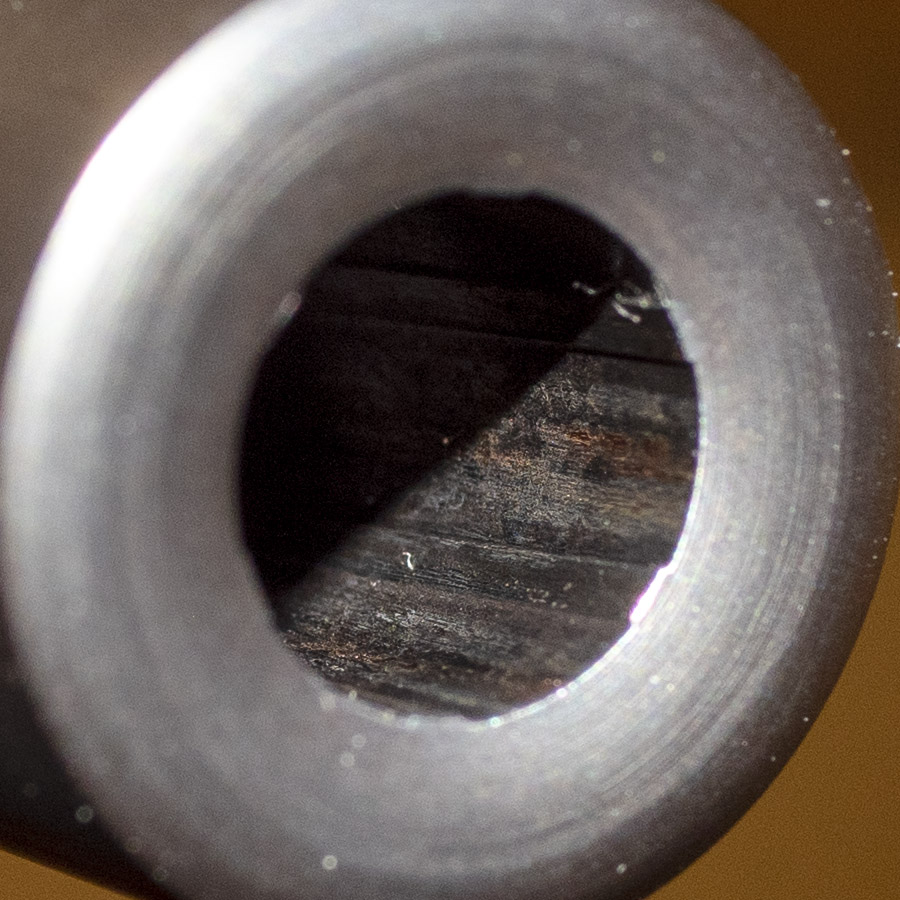

I realized I still had a lot of copper and lead streaking in the barrel and I went to work on it with Hoppes No. 9 and Butch’s Bore Shine. That reduced most of the copper, but the lead was not giving up. A bit of online research, and what do you know: Solvents (like Hoppes or Butch’s) don’t affect lead at all. I’ve been a shooter for 50 years and that was news to me. Nope, lead has to be mechanically removed. I soaked a pad with Kroil penetrating oil, ran it through the bore and let it soak for a while, and then I ran a bore brush down the barrel repeatedly. It was better, but it needed more. I repeated the process several times over the next two days and got the bore down to this:

The bore wouldn’t get any cleaner that what you see above. To the naked eye, it looks clean. But then, to the naked eye the first photo looked clean. I was probably penalizing my inspection with that macro photo. I know I could probably get it cleaner with something like JB Bore Paste, but I’m hesitant to use an abrasive in the bore.

I loaded various permutations of IMR 7828 and H1000 propellants, and the Sierra 200-grain jacketed hollowpoint boat tail and Remington 180-grain jacketed soft point bullets for the factory level loads.

So how did the above combinations perform at 100 yards? Take a look:

The rifle is unquestionably capable of better results than you see above, but not with me. I’m usually not recoil shy, but this 300 Weatherby at factory ammo levels is a bit beyond what I’m willing to live with on a regular basis. A better rifleman could probably keep most of the above loads below an inch. But an inch and half is good enough for me, and several of the factory-level loads above did that. I can hunt with this rifle, and that’s what I’m going to do.

So what’s next? I found a couple of boxes of 180 grain Hornady jacketed soft point bullets, and I have a few Nosler 180 grain bullets as well. I’m going to try a few loads with them. I haven’t tried too many loads with lighter bullets, mostly because earlier results were disappointing. But I haven’t given up on the lighter bullets. I’m going to revisit a few loads with them. And I have a couple of powders I want to try as well. Bottles of powder don’t last long with a 300 Weatherby, though, when you look at kind of powder charges these cases demand. When you’re dispensing 80 grains of propellant per round, 100 rounds of 300 Weatherby consumes an entire bottle of powder. And powders (like everything else) are somewhat difficult to find these days.

Truth be told, the 300 Weatherby is specialty item, and it’s a punishing beast. It’s surprising how much of an increase in recoil there is in going from a 30 06, a 300 H&H, or a 7mm Magnum (in either Remington or Weatherby flavors) to a 300 Weatherby. But shooting the 300 Weatherby is fun in its own way. I sure enjoy mine.

If you shoot a 300 Weatherby, we’d like to hear your thoughts on the cartridge and the rifle. Please leave a comment here on the ExNotes blog.

More Tales of the Gun…revolvers, rifles, pistols, pellet guns, reloading, and more. It’s all right here!

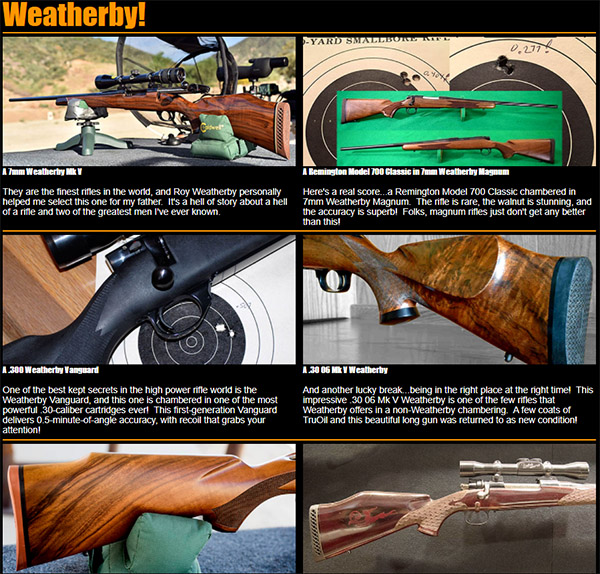

More Weatherby? You bet!

Never miss an ExNotes blog!

Keep us afloat! Hit those popup ads!

You are correct, it’s no understatement that the 300 wby mag recoil is harsh! Mine is used for hunting only. It was previously set up for copper jacketed hunting bullets; however, it is now set up for Kalifornistan’s no lead rule with Barnes TSX bullets. I couldn’t get Hornady no lead or the Barnes TTSX (polymer topped) to group worth a darn in my rifle, but the regular Barnes TSX non-tipped 168 grain bullets group under an inch at 100 yds and has a great trajectory out at 300 yards (about an 8″ drop). This is a hunting only rifle now as the zero between lead core and non-lead bullets are so different it not practical to switch back and fourth. Each season I will fire one or two shots at the range to check the scope – usually only one shot needed as my Nikon 3×12 with Lupold scope mounts doesn’t seem to move around at all from season to season. After my shot or two, then it’s out into the field. Incidently, I’ve never seen a bore on any Weatherby looking like yours. Since you plan on hunting with it in this crazy lead-free state of ours, why not just use a copper fouling remover, or even a light shot of the Remington 40x bore cleaner to remove the lead and copper, then develop a non-lead hunting load and stay with it? You have plenty of other great rifles to target shoot and play around with cast lead bullet loads to mess up your beautiful Mark V! Just sayin’

Jose, I have a box of 150-grain Hornady copper monolithic bullets and I may try those. Thanks for commenting.