I’ve been cleaning out the shed on and off for about four years now. When we first moved here we stuffed everything into the shed. There was no time to sort through the junk. We had to return the Penske truck. After the junk sat there a few years the mice made a lot of decisions for us: if it was chewed up we tossed it.

I had tools at my work, tools at the house, tools at The Love Shack, three of everything. I just can’t bring myself to toss out tools. I have some home-built tools that no longer serve a purpose but I hang on to them. Because you never know when you’ll need to remove the centrifugal oil filter on a Honda 305.

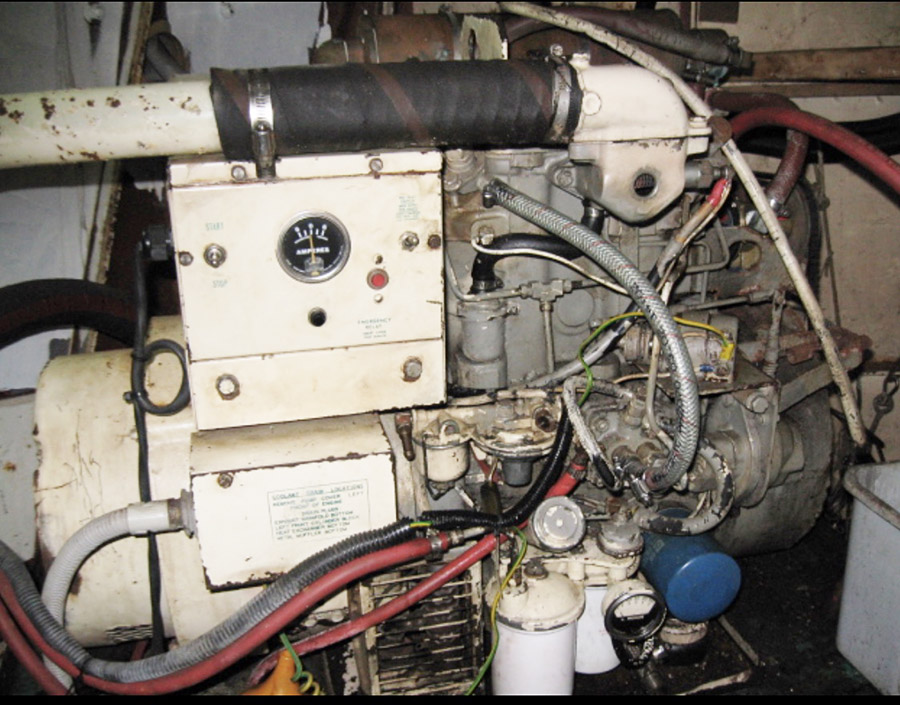

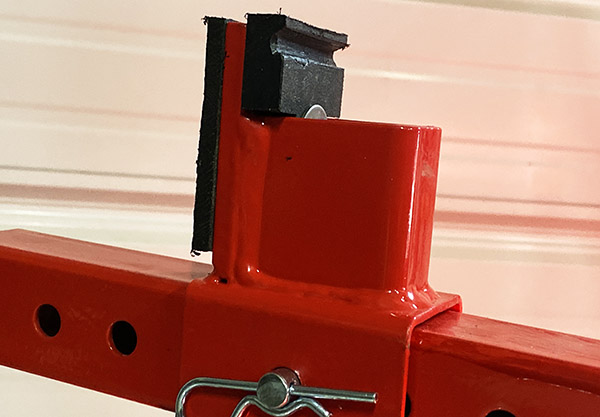

This wrench was made from a cut down socket and a rear fender support from a Sportster. It fits the output flange nut on a boat V-drive. The output flange sits pretty low in the bilge and after a while the salt water splashing around in the bottom of the boat corrodes the seal. To remove the seal you have to separate the prop shaft from the V-drive. The problem is the prop shaft will only slide back a few inches before the prop-shaft flange hits the stuffing box. With this set up I could change a v-drive seal without pulling the engine. It was a stupid move on my part because at the time I was paid by the hour. The faster I went the less I earned. I still keep the wrench; maybe it will fit something else someday.

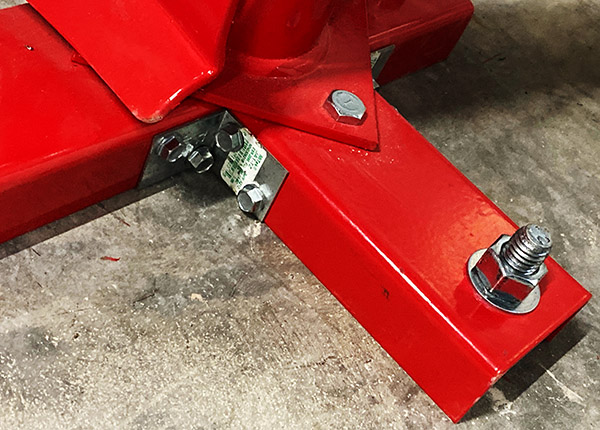

I mentioned the stuffing box and here’s the cut down pipe wrench I used to remove the packing nut and loosen the lock nut. Stuffing boxes are used where the prop shaft goes through the boat hull, a bronze casting called a shaft log. The stuffing box is a large nut that has several rows of flax packing, also called cat gut. These rows of packing are fitted into the packing nut or the shaft log depending on the design of the shaft log.

The flax packing seals the shaft log where the shaft enters so that water won’t leak into the boat…almost. In practice you want to leave a small drip, maybe a drop every 30 seconds, for a water supply to cool the stuffing box. If you crank down on the packing too much you can burn up the flax and the shaft log will leak. The pipe wrench is short because the stuffing box nut is large and it’s always hard to access between the stringers of the boat. You can buy a store bought stuffing box wrench but they are made like a flimsy adjustable wrench with a cheesy wing nut to lock the jaws into position. Trust me: the pipe wrench works better. A hammer also works but tends to damage the bronze stuffing box.

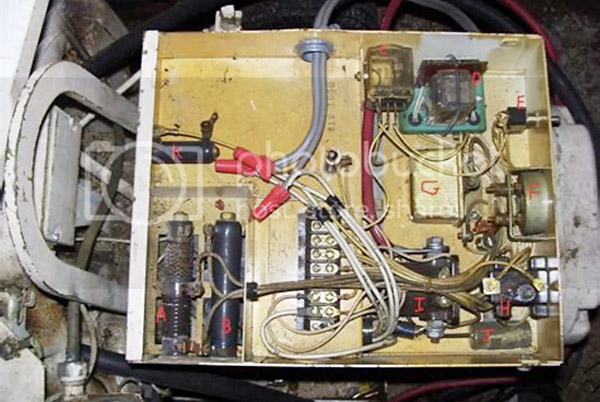

I didn’t make the dial indicator, just the Z-shaped bracket. This tool is used to set the timing on a 1971 360 Yamaha Enduro. The ’71 Enduro (and other years) has an angled sparkplug hole. The angled hole precludes measuring the piston stroke through the plug hole. With the cylinder head removed this tool bolts up and can measure the stroke. You have to know the piston position to accurately set the ignition timing. Once you’ve set the correct fire position there is a little tab inside the flywheel area that lines up with a flywheel mark. Bending the tab to line everything up will save you from measuring the piston stroke every time you want to adjust the points. It’s a use-it-once type of tool unless you disturb the timing marks. Godzilla runs so good I may never need it again.

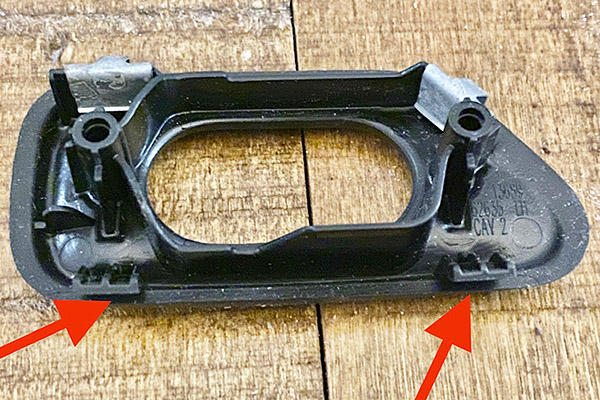

This tool is made from Monel, a metal found around boat yards, which isn’t important to its function. There are a few other holes in the tool but I’ve forgotten what they do. The two holes marked by the red arrows will fit a Norton Lockheed front disc brake caliper. In operation you insert a couple drill bits into the tool; the bits line up with two holes drilled into the Lockheed caliper. The caliper plug this tool fits unscrews and allows removal of the caliper piston. You need this long lever because the plug gets pretty tight after 35 years. I’m hanging on to the tool because I may own another Norton one day.

At one time my dad and I owned BMW motorcycles. He had the 600cc and I had the 750. These were early 1970s models with the new, suitcase engine. In building the suitcase engine BMW relocated the cam below the crankshaft so the pushrod tubes were below the cylinder rather than above like on earlier engines. This was done to raise the cylinders higher in the bike allowing steeper lean angles in the corners. The problem was the pushrod tubes leaked oil where they contacted the crankcase. This tool slips over the pushrod tube and by tapping the base of the pushrod tube you could tighten up the seal area. It sounds crude but it was easier than pulling the heads to install new pushrod tube seals. I think you can buy a factory tool that looks much better than mine but does the same thing. I’m not adverse to owning the early GS 800cc, the ones that are clean and light and don’t have all the useless garbage BMW loads onto new motorcycles.

This tool is used to remove the nut from a Honda 305 centrifugal oil filter. I had two 305 Hondas. Those bikes had beautiful engines that were made extremely well. Early Hondas had a spinning cup type filter that oil circulated through. In the spinning motion heavy particles suspended in the oil were slung outward, clean oil flowed through the center. It was a good oil filter and if you wanted to take the engine apart like I did you needed this tool. After thousands of miles you would remove the right side cover to gain access to the filter. A wire clip held the o-ringed lid on the filter and I’d pull the thing off for cleaning. It wasn’t unusual to find 1/8-inch of compacted swarf stuck to the walls of the filter.

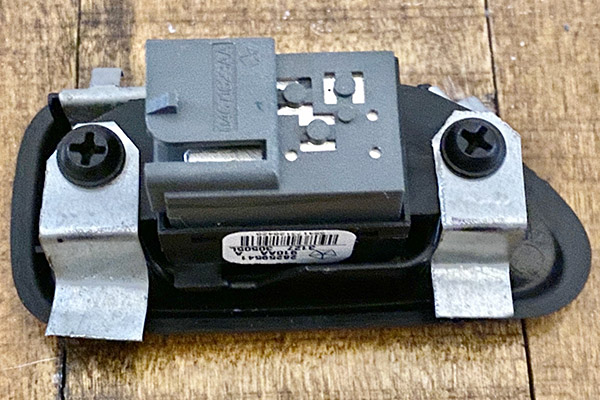

Back to boats. This tool is used to remove the macerator from Raritan Crown marine toilets. Working on boats isn’t the glamorous job that you see in the movies. Sometimes you had to fix toilets. The Crown was a very popular toilet back in the day. It used a large starter motor to spin a macerator and two rubber impeller pumps. One pump supplied seawater to the bowl then a macerator chewed up the poo and finally another impeller pumped the mash to a holding tank or overboard depending on how far offshore you were. After much use the seals would start leaking and the stuff leaking out wasn’t peppermint.

You had to disconnect hoses and the bowl then turn the motor (usually) to get to the end plate. Small straight slot screws held on the plastic end plate, removing the end plate allowed access to the macerator and the poo. The macerator had two pivoting chopper arms; removing these arms allowed you to screw the puller tool onto the macerator and a center bolt would pull the macerator. It was not a fun job. I wish I never made the puller tool. I could have told customers, “Sorry I don’t have the tools to fix your toilet.”

I have more homemade, or as we say in the south “ho-made” tools that I may write about on a day like today, a day when I’m sifting through the accumulated junk of my life.

More product reviews!

More Joe Gresh!

Never miss an ExNotes blog!