A Trip To Death Valley!

Brown Motor Works in Pomona, California, hosted a chili cookoff in March 2008, which was immediately followed by a weekend trip to Death Valley. At the time, I’d been a California boy for 30 years, but I’d never been to Death Valley. I always wanted to go. And, I love chili. Free chili…lots of photo ops…good weather…and a motorcycle ride to a place I’d never been before. It seemed like a no-brainer to me. It was a ride I had to make.

Kawasaki’s KLR 650

I had purchased a 2006 KLR 650 a year or two earlier from my good buddy Art at the Montclair Kawasaki dealer, and something strange happened: I found I was enjoying the little KLR more than the other big roadburners I owned. At that time, I had gone way overboard in acquiring motorcycles. I had a TL1000S Suzuki, a Harley Softail, a Honda CBX, a Triumph Daytona 1200, and a Triumph Tiger 955 (and I think I owned them all at the same time). There was something about the KLR, though, that I liked, and I found myself riding it more often than not. All the guys I rode with either had BMWs, Harleys, or Triumphs, and my KLR was the smallbore of the bunch. I didn’t care. I liked riding it. To my surprise, I found that riding a smaller bike was more fun.

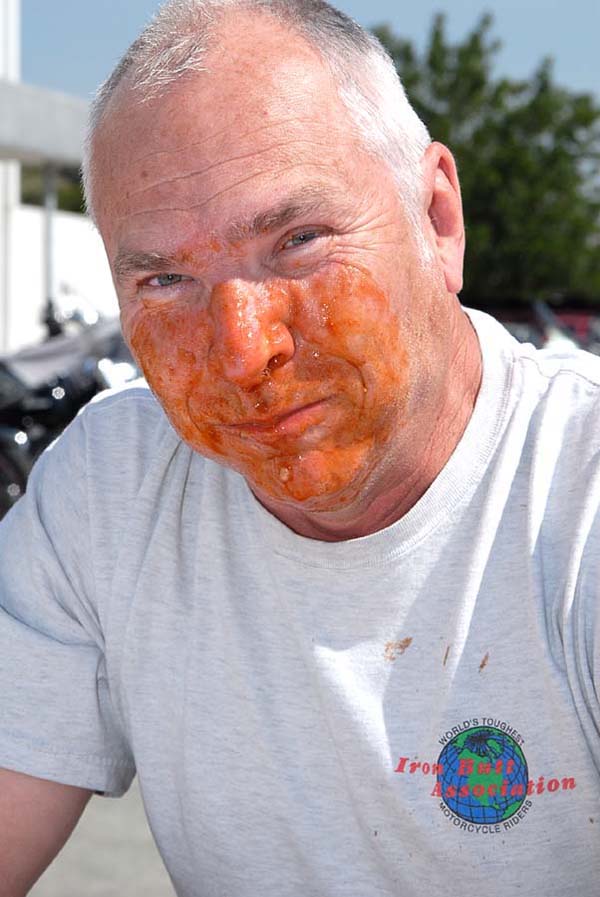

The Chili Cookoff

On To Mojave

The guys at Brown Motor Works planned to leave at the end of the day, but I didn’t want to hang around until then. Immediately after grabbing a few photos from the chili contest, I was on the KLR headed east and then north into the Mojave Desert.

Baker and The Mad Greek

Baker is a wide spot in the road along the I-15, and it’s a jumping off point for Death Valley. It is a funky place with a couple of poorly-maintained and overpriced gas stations, the world’s tallest thermometer, and a cool restaurant called The Mad Greek. The Mad Greek is a place that seems to always show up in any movie about a road trip to Vegas. I have yet to find a Greek in the place, but the food is good and the staff is friendly.

Into the Valley of Death

After a breakfast at the Mad Greek the next morning, we road north toward Death Valley. There’s nothing out there but great roads and the Mojave for the 80 miles or so to the park entrance, and the Beemer boys were riding at speeds well in excess of 100 mph so I couldn’t keep up. The KLR might see 100 on a really good day, but I didn’t care. I wanted to stop, smell the roses, and get good photos. Riding by myself didn’t bother me at all. I preferred it.

Artist’s Palette

One of the cool spots to stop in Death Valley is a hilly area called Artist’s Palette. Each hill has a different dominant mineral (and a different color), and the result is something that looks like an artist’s palette. It’s a very cool thing to see.

High Prices and Photo Ops

Death Valley’s claim to fame is that it’s one of the lowest spots on the planet. It’s also in one of the more remote places on the planet, which meant that fuel costs were unusually high. All made for interesting photos.

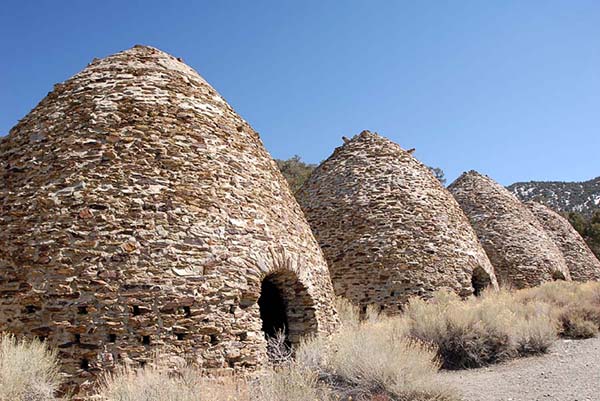

Wildrose Road and the Charcoal Kilns

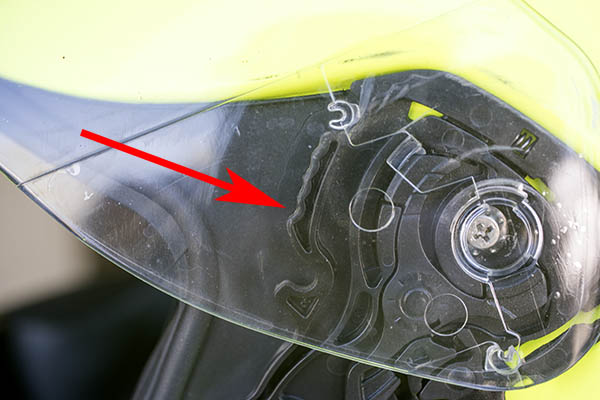

The Gear

I had a Nikon D200 digital camera when I did this trip and the first-generation Nikon 24-120 lens with a polarizer, and it did a good job for me. I think it was a 10 megapixel deal and that seemed like a lot in those days. I kept the D200 for a long time and I had a lot of fun with it. I used it for all of the photos you see here. It was big and bulky, and as I recall, it took all of the space in one of the Kawasaki saddlebags I used with my KLR. It was only a weekend trip, and the other saddlebag was enough for my other stuff. I like to travel light and the arrangement worked fine for me.

Death Valley: The Bottom Line

If you’ve ever thought about taking a ride to Death Valley, do it. Take a camera, too. Trust me on this: You won’t be disappointed. As a rider and a photography enthusiast, I had a great time. The KLR 650 was more than enough motorcycle, I felt it was a good bike for a trip like this, and I concluded that Death Valley is doable on just about any motorcycle (especially if you mostly stick to Death Valley’s paved roads, as I did). The photo ops in Death Valley are stunning. If you live in southern California, it’s an easy weekend trip.

One day was not enough, though. There was a lot of Death Valley left to see, and I knew I’d be back.

There’s more coming on Death Valley and a bunch of other great rides. Sign up here and never miss an Exhaust Notes blog!