By Joe Berk

This is an update on my 9mm 1911 sudden unintended disassembly saga. I will address four topics:

-

-

- Zeroing in on the cause.

- Rework of the ammo I had loaded on my Lee turret press.

- My reconstituted 9mm 1911.

- Preventing a recurrence.

-

Let’s get into it.

Zeroing In On The Cause

I’m down to thinking the 1911 event was due to either of two causes: A double propellant charge, or bullet setback (i.e., the bullet slid deeply into the case as the round was being chambered, thereby raising the chamber pressure).

A Double Charge

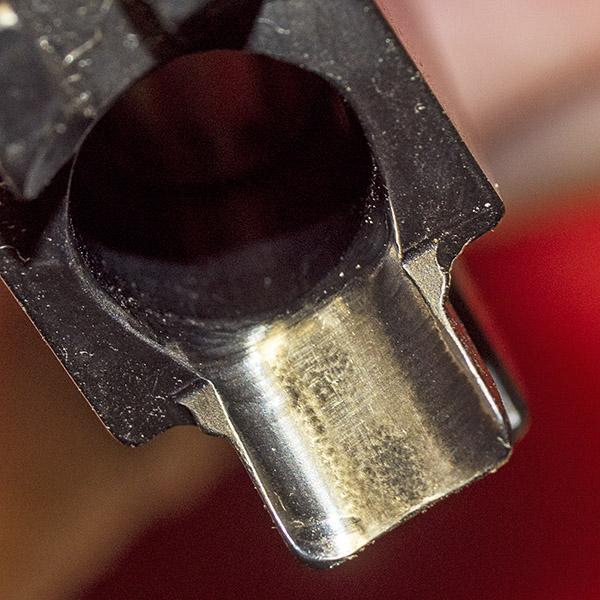

I did a Google search on double-charged cartridges, and what do you know, there’s actually someone out there who did the same thing I did. He caught it on video and posted it with a photo of the case. His burst cartridge case sure looks a lot like mine.

If you compare the photo at the end of the above video to the case stuck in my chamber, they are identical. I’ve convinced myself that this is the most likely of the two scenarios, but I’ll describe the other scenario (bullet setback) as well.

Bullet Setback

What has me thinking deep thoughts about the second failure mode (pushing the bullet deeper into the case during chambering) is that I think it is relatively easy to screw up while reloading and induce this failure, and from what I’ve read, 1911s are more prone to do this than are other semi-autos.

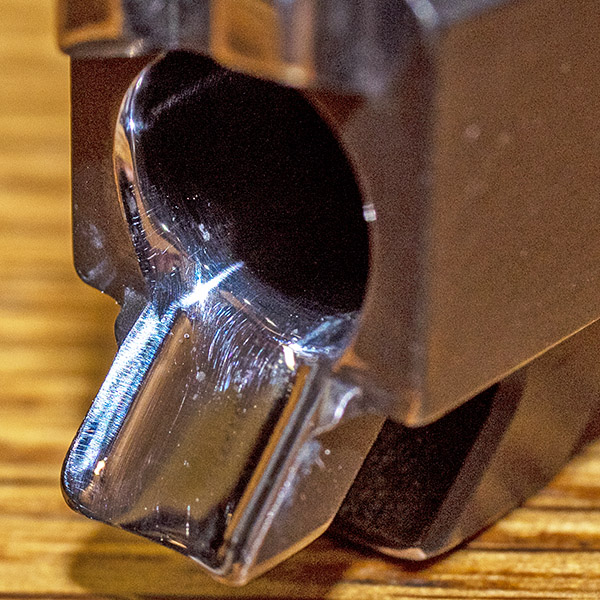

Let’s discuss screwing up the reloading process in a manner that could induce bullet setback. On my Lee Classic turret press, bullet seating and crimping occur in two separate operations (seating refers to pushing the bullet into the case; crimping refers to locking the bullet in place by crimping the cartridge case mouth). The third (of the four) dies seats (but does not crimp) the bullet; the fourth die applies a taper crimp to the bullet. Here’s the screwup: I’ve had at least a couple of instances where I took the cartridge out of the press after seating the bullet (but before crimping it). I know; you’re thinking that’s stupid, and I can’t argue with that conclusion. I don’t know why I did it (too eager to see the completed round, maybe?). I caught myself, returned the cartridge the press, and crimped it. But it’s possible I missed the crimping step on a cartridge.

I think setback is the less likely of the two failure modes discussed here. I tested the crimp by tapping on the bullet with a rubber mallet and it didn’t move. Failure to crimp or a weak crimp may have caused setback, but on properly crimped bullet, I don’t think setback will occur. Also, when I made the cartridge shown in the photo above on my RCBS Rockchucker press, it took more effort than I thought it would to seat the bullet as deeply as you see in the photo (and the case had not been crimped). I doubt that simply chambering the round would drive the bullet in that deeply (even without a crimp). If you think otherwise, please leave a comment below.

Gun Design and Bullet Setback

As mentioned above, bullet setback is more likely to occur on a 1911 than it is on other semi-auto handguns. It has to do with cartridge location in the magazine, and how it feeds into the chamber. On more modern handguns, the top round in the magazine sits higher in the gun than it does on older design guns. When the slide shoves the round forward, cartridges in more modern handguns have a straighter path into the chamber. On a 1911, the top round in the magazine sits lower in the gun. When the slide pushed it forward, the bullet impacts the ramp, it has to stay situated in the cartridge case without experiencing setback, and the cartridge has to rotate up and then into the chamber. Because of this, a 1911 is more likely to experience bullet setback than is, say, a gun like the S&W Shield.

That’s not to say the Smith and Wesson Shield is a better design or that it’s all sunshine and rainbows. There’s a tradeoff the engineers made on the Shield. Yep, the Shield’s higher cartridge position makes for a straighter path into the chamber. It also allows for higher capacity in a smaller gun (my little Shield holds 8 in the magazine and one in the chamber). But the higher cartridge position can induce another issue: Failure to extract and eject.

During extraction, the round being extracted has to drive the magazine’s top cartridge down into the magazine as it is being extracted. it does so by using the next cartridge’s bullet as a cam surface. The rear edge of the cartridge being extracted bumps into the mag’s top cartridge, and then it has to drive it down so the case can exit the gun after firing. As it uses the bullet of the mag’s top round for that cam surface, the rear of the cartridge case rim encounters the case mouth of the mag’s top cartridge, and that can cause a failure to extract and eject. It’s happened to me. I’ve found the Shield is sensitive to ammo brand, bullet configuration, and crimp. Too much crimp, and the cartridge goes too deep into the Shield’s chamber and the firing pin won’t light the round off. Too little crimp and it jams in the manner described above. Too little crimp and it might experience bullet setback. Like most things in life, the design is a tradeoff.

Again, I don’t think bullet setback is what happened in my 9mm 1911. I’m including it here simply because it is interesting and relevant to this discussion.

Ammo Rework

One of the personally dismaying and embarrassing things about blowing up my 9mm 1911 is that it immediately threw into question the approximately 1500 rounds of 9mm and .45 ACP ammo I had reloaded on the Lee turret press.

I thought I could use weighing the rounds as a way to screen for double loads, but on both the 9mm and the .45 cartridges, the weight variation exceeds the weight of the powder charge. That means I could have a double charge and if it was in a lighter round, it would be within the variability for the loaded cartridge. So weight was not a way to screen. I know there will be keyboard commandos with advice to stick to one case manufacturer (or to segregate cases by brand), but the same variability problem exists even when cases are segregated (I’ve checked). I wish the self-styled “experts” on Facebook would slither back under their rocks (or at least refrain from commenting when they just don’t know what they are talking about, which is most of the time).

I’ve disassembled and reassembled the 800 9mm rounds I loaded on the Lee turret press. I did not find a single one with a double charge. I used my buddy Greg’s RCBS collet bullet puller for this on my 9mm ammo and it worked like a champ with minimal or no bullet damage. Surprisingly, with all brands of brass, after pulling the 9mm bullets from crimped cartridges I did not have to expand the case mouths again to reseat the bullets. They slid right in. I just seated them to the right depth and crimped them again. Reusing the bullets didn’t seem to affect accuracy, either.

The RCBS collet bullet puller did not work on my .45 ACP ammo. The .45 collet couldn’t get a good enough grip on powder coated 230-grain roundnose bullets or on my 185-grain cast semi wadcutters. I tried one of those Grip-N-Pull devices and that didn’t work, either. The bullets slid right out of it. To disassemble the .45 cartridges, I had to use an impact bullet puller, and that was tough sledding. It takes forever. I don’t like impact bullet pullers, but hey, it is what it is. And what it is, well, is a lot of labor. I’m working it a little at time, at a rate of about a box per week. Three or four months and the rework will be in the rearview mirror.

That double charge sure turned out be one expensive mistake, both in terms of damage to the 1911 and the need to rework a lot of ammo. Live and learn, I guess.

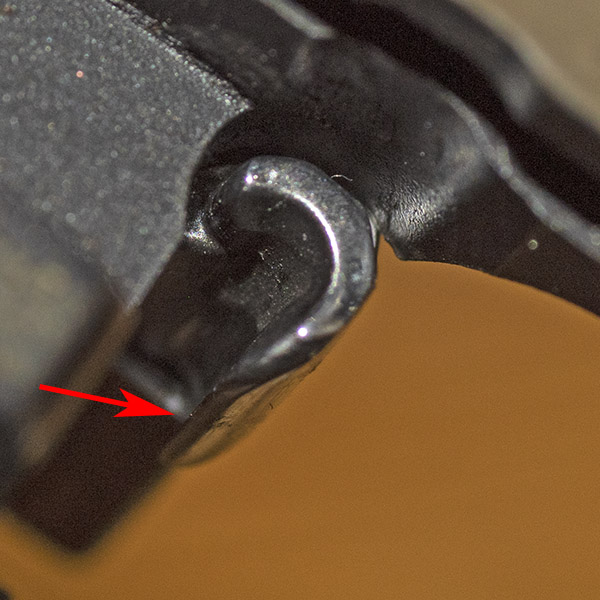

The Reconstituted 1911

TJ (of TJ’s Custom Gunworks) worked his magic on my 9mm 1911. As mentioned in a previous blog, in addition to addressing the damage from the burst cartridge, he polished the barrel and ramp, refit an extractor that actually works (shame on you, Springfield Armory, for letting this one get out of the factory with an extractor that didn’t even contact the cartridge case), he recontoured the slide release and the slide release pin (shame on you again, Springfield Armory, for a slide release that was extremely difficult to install), he fit a one-piece guide rod (which is what I asked him to do), and he did one of his magnificent trigger jobs (this 1911 has a “breaking glass” 2 1/2 pound trigger now, with zero creep and no discernible takeup). This 1911 is a pure joy to shoot. I loved it before and I love it even more now. That target at the top of this blog? It’s a full box of my reloaded 9mm ammo (50 rounds) fired without resting the gun on anything. No failures to feed, no failures to eject, no misfires, and every bullet hit in the 10 ring.

Preventing a Recurrence

Wow. Where to begin.

I am implementing a number of changes in my reloading to prevent this from occurring again:

-

-

- I’m slowing down and paying more attention. Duh. I’m no longer complacent. Duh again.

- I’m installing better lighting on my press.

- I’m standing up so I can see into the cartridge case.

- I’m switching to a bulkier powder so that a double charge, if it ever occurs again, will spill over the case mouth and make a big, impossible-to-ignore mess.

-

I don’t mind sharing with you that when this first occurred, my thought was to abandon the Lee Classic turret press and return to loading on my single stage RCBS Rockchucker press. Double charging a case using a single stage press is (in my opinion) a much less likely thing to happen, and in 50 years of reloading on the Rockchucker, I’ve never had it happen.

I have a friend who works for Colt in their customer service department, and he tells me that when he sees a blown up gun sent in, there’s usually a progressive or a turret press somewhere in the story. But good buddy Paul told me to think about it a while longer and I did. I’m back to using the Lee turret press, but I’m a little older and a lot wiser now. The older part wasn’t really necessary, but the wiser part is and hopefully, readers can benefit from my screwup.

Slowing Down and Paying Attention

You know, when I worked in the munitions industry I participated in two fatality investigations where inadvertent detonations were involved. Multiple human errors caused those inadvertent detonations, and one of the key human errors was complacency. That’s what I had become using the Lee Classic turret press: Complacent. I’d been reloading for so long I became entranced with the turret press’s speed, and I started reveling in the thousands of rounds I was cranking out (and it was, literally, thousands of rounds). I always knew that double charges or skipped steps (like crimping) were really, really bad, but I just never thought I’d be the guy making either mistake. I wasn’t taking the time I needed to and I became complacent. That’s changed. I’ve slowed the pace, and you can bet I’m looking into every case immediately before I place a bullet on top to make sure I haven’t double charged it. You can also bet that I’m making sure I hit the crimping step on every round. I’ve actually posted a sign on my reloading bench with the best advice I’ve ever given myself: Slow down.

Better Lighting

Good buddy Duane (who is both smarter and better looking than me) also reloads with the Lee Classic turret press. Duane mounted a light above his press to allow better visibility into the charged case. I’m going to do the same.

Standing Up

I used to sit at the reloading station. My bench, though, is higher than a standard work table (it’s how I had it built 50+ years ago). When I’m seated, it’s not as easy to see into the case. I reload standing up now, and that allows seeing directy into the case.

Bulkier Propellant

My last change concerns the propellant. One of the things I investigated shortly after my 9mm hand grenade episode was if it was possible to get a double charge into a 9mm case. With the load I was using (5.4 grains of Accurate No. 5), the answer was yeah, you could. It even had a little room left over. My thinking at the time was that I needed to go to a propellant that would overflow the case if I double charged it. In the past, I’ve found 4.8 to 5.0 grains of Unique with the 125 grain bullet is a marvelous 9mm load. Doubling that (i.e., 9.6 grains of Unique will overflow a 9mm case) and if that happens when loading, that’s a good visual indicator that something’s wrong. So, from here on out when using the Lee turret press, my load will be 4.8 grains of Unique. That only works for 9mm, though. Other cartridges (the .45 ACP, for example) will handily swallow a double charge. There, it’s back to paying serious attention (which we need to do on everything when we reload; it’s just using a propellant that will spill over with a double charge adds an additional indicator if things aren’t done correctly).

Incidentally, when this happened, I wrote to Lee and asked them if they offered any accessories to prevent a double charge (my Star reloader has a mechanical feature that prevents this from occurring). The answer was no, but Lee advised using a propellant that, well, read the above again and you’ll know. I checked the literature that came with the Lee Classic turret press kit, and sure enough, Lee has a recommendation in there to do exactly what I describe here.

Hornady’s Powder Cop

When I posted earlier blogs on Facebook, a few people mentioned a reloading cop. In 50 years of reloading, I’d never heard of such a thing, but I found it on Amazon. Hornady’s Powder Cop die is a die with a pushrod indicator. You add it to a vacant station on the reloading turret after the propellant charging station and when the charged round goes into it, if the case is double charged the rod will go higher than it normally does.

I don’t think the Powder Cop is the answer for several reasons. The Lee Classic turret press doesn’t have an empty station in its turret (all four stations are taken by the Lee 4-die set), you would have to notice that the pushrod indicator rose marginally higher than it was supposed to, and I believe that if a double charge was present, the pushrod might just push into the powder and not rise enough to indicate the double-charge condition. The Powder Cop might be right for some people, but my equipment can’t use it and I don’t think it’s an effective check. If you missed the double charge, you would probably miss the rod extending upward a bit further, too.

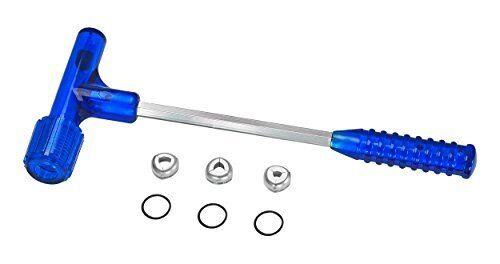

The RCBS Lockout Die

RCBS offers their lockout die which is, in my opinion, the best option for preventing a double charge on a reloading press, if the press that has an open station. If the case has an overcharge or an undercharge (or no charge), the lockout die locks the press, which positively lets you know that something isn’t right. It’s a clever mechanical device that detects either and overcharge or an undercharge and then stops the process.

Unlike Hornady’s powder cop die, the RCBS lockout die isn’t just a rod moving up and down. The lockout die stops the show and forces you to check the cartridge that has locked up press movement. I think it’s a much better approach. The problem, though, is that you need that extra station on either a turret or a progressive press, and I don’t have that on the Lee Classic turret press (so for me it’s a nonstarter). What it says to me is that if I were to buy a new press, I would want one that has an extra station. I think the lockout die is a stellar idea; I just don’t have the real estate for it on my press.

The Bottom Line

I’m convinced that I had a double charge in the round that burst in my 1911. I’m also convinced that it’s on my to prevent it from happening again. As explained above, here’s what I’m doing:

-

-

- I’m slowing down and paying attention to what I do. There is no place for complacency in the reloading world.

- I will continue to use my Lee Classic turret press, but I’m installing better lighting and standing up so I can see into the cartridge case.

- I’m switching to a bulkier powder so that a double charge, if it ever occurs again, will spill over the case mouth and make a big, impossible-to-ignore mess.

-

So there you have it. If you have any thoughts on any of the above, I’d sure like to hear them.

Never miss an ExNotes blog:

Check out our Tales of the Gun page for more firearms and reloading articles.