The .35 Whelen is an interesting cartridge. A wildcat formed by necking .30 06 brass up to .35 caliber, it’s been called the poor man’s .375 H&H, but the price of ammo would suggest it’s anything but a poor man’s cartridge. A box of 20 factory rounds when I checked just a few minutes ago ranged from a low of $50 to a high of $72. For 20 rounds? Gimme a break!

I like to shoot, but I’m a cheap SOB and truth be told, I don’t like beating my self up with factory .35 Whelen recoil. Roll that up with the good luck I’ve been having with good buddy Ralph’s Boudreau Bullets in several handguns and I wondered: Could I have Ralph make .35 caliber powder-coated pistol bullets sized to .359 inches? You see, cast pistol bullets for the .38 Special or .357 Mag are ordinarily sized to .358 inches (the sizing operation occurs after the bullets are cast when they are swaged down to the desired diameter). But .358-inch diameter bullets probably wouldn’t work in the Whelen. The .35 Whelen rifle has a bore of .359 and shooting bullets sized to .358 would allow the propellant gases to escape around the bullet as it traveled down the barrel. That would melt the sides of the bullet and create God-awful leading. A tighter fit (with .359 bullets) ought to work better, and powder-coated cast pistol bullets are inexpensive. Inexpensive is good. Did I mention I’m a cheap SOB?

I’ve loaded jacketed pistol bullets in the .35 Whelen before, I’ve loaded cast pistol bullets, and I’ve also loaded cast rifle bullets from Montana Bullet Works. The Montana bullets are great and the Whelen performed well with them. The jacketed pistol bullets worked well. The cast pistol bullets I tried before didn’t work well (you can read about that here). The premium cast Montana Bullet Works bullets are not cheap (nor should they be). I wanted something inexpensive so that I could play with the Whelen at recoil levels comparable to a .22. Maybe Ralph’s powder-coated pistol bullets would work.

Ralph obliged, and when my .359 158-grain cast semi-wadcutters arrived, the fun began. I did my research on the Internet about what loads other folks had used with cast pistol bullets in the .35 Whelen, or at least I attempted to. Like everything else on the Internet, opinions were all over the map.

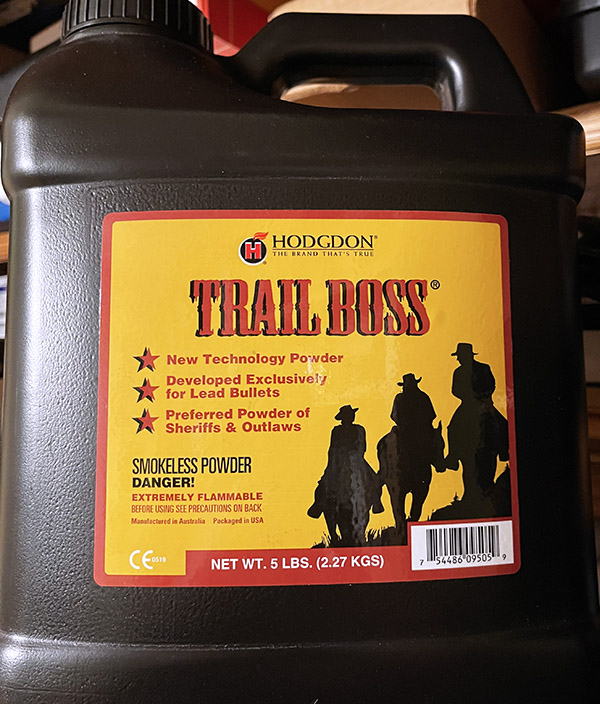

I initially went with what one forum commenter fervently quoted: Low charges of Trail Boss were the way to go with 158-grain cast bullets. He was wrong, as least as far as my Ruger No. 1 is concerned. I tried 13.0 grains and the groups at 50 yards were (no kidding) about a foot in diameter. This might be okay for a shotgun, but not a rifle. The groups were lousy, but I noticed that the bore was clean. Ralph’s powder coating, which had worked well in keeping a handgun bore clean, worked well in the longer rifle barrel as well.

I next tried Unique propellant (first with 13.0 grains, and then with 15.0 grains), which had worked well for me in the past in a variety of cast rifle loads for other cartridges. Nope, both of these loads shot lousy groups, too, and they leaded the bore way more than Trail Boss. Trail Boss is actually a faster powder than Unique, so the slower-burning Unique was driving the bullets to higher velocities.

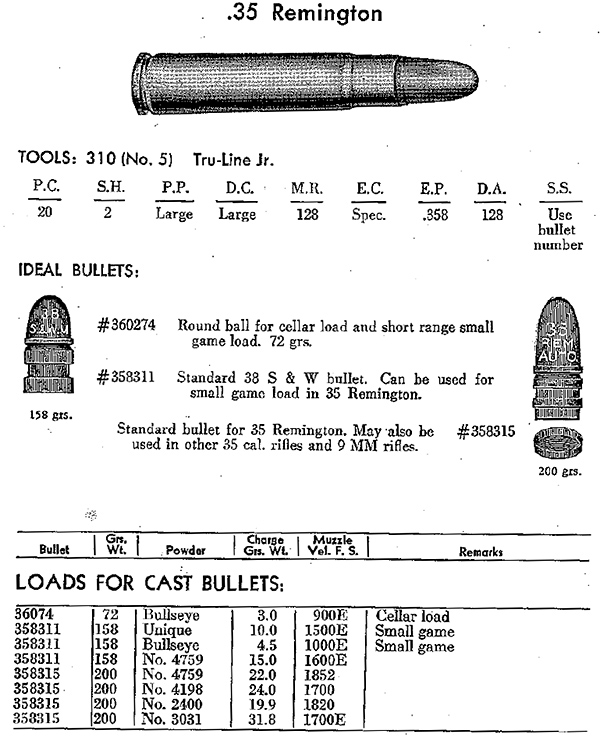

Then it was on to Bullseye. I found a few references to these loads in various forum comments, but Bullseye is a dicey powder and I wanted a better load data source than some yahoo on a gun forum. I hit paydirt when I found an old Ideal reloading manual and it had a Bullseye load for the .35 Remington (the .35 Whelen was still a wildcat cartridge when this manual was published and there was no load data for it). I figured with the .35 Whelen’s bullet weight and case volume, I wouldn’t get into trouble using the .35 Remington load. I tried it and I tried a few others with a bit more powder (there were no pressure signs), but nope, it was not to be. I still had terrible groups at 50 yards.

Hmmmm. Maybe it’s a powder position thing, I wondered. I called Ralph at Boudreau’s Bullets and chatted with him. Ralph explained that when the powder doesn’t fill the case, powder position makes a huge difference in accuracy even in a 9mm pistol cartridge. Okay, I can fix that, I thought. So after loading my brass again with the same light Bullseye loads, I inserted a cleaning patch in each cartridge to hold the powder up against the primer. Still no cigar, though: The groups remained stuck on atrocious. It was cool, however, seeing the cleaning patch threads dissipate downrange in the scope after each shot. One good thing that came out of the Bullseye loads was that they didn’t lead the bore. Well, maybe two good things: I didn’t blow myself up. Okay, three good things: None of the bullets stuck in the bore.

I was just about ready to give up trying to make the powder-coated .359 Boudreau bullets work in the Whelen when my mind returned to the powder position question. Okay, I thought, the cleaning patch wad trick (a noble thought) was a bust. But Trail Boss might still be the way to go, even though the lighter load wouldn’t group. Those earlier 13.0-grain Trail Boss loads left a lot of unoccupied space in the case. The beauty of Trail Boss is that you can load all the way up to the bullet base (thereby completely eliminating the powder position issue, as the case will be full) without overpressurizing the cartridge. So that’s what I did. I measured where the base of the bullet would be at a cartridge overall length of 2.910 inches and I filled a case to that level with Trail Boss. The magic number was 19.3 grains. I adjusted my powder dispenser and went to work.

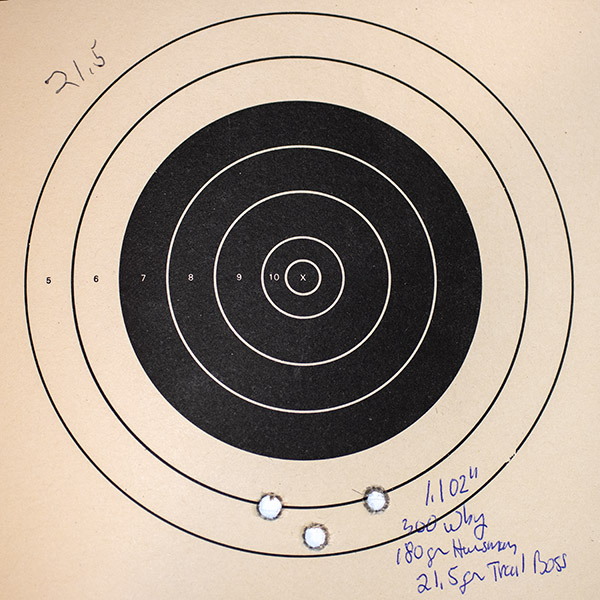

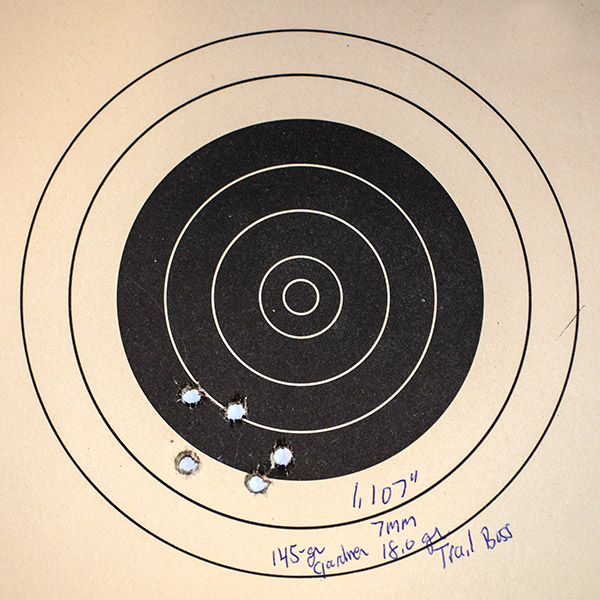

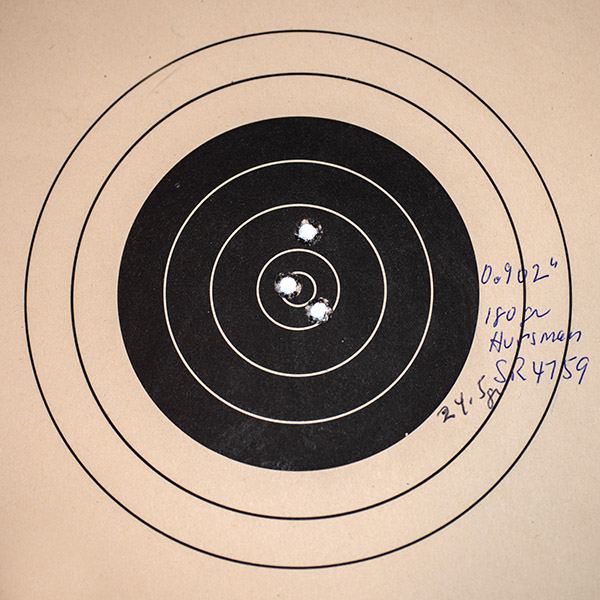

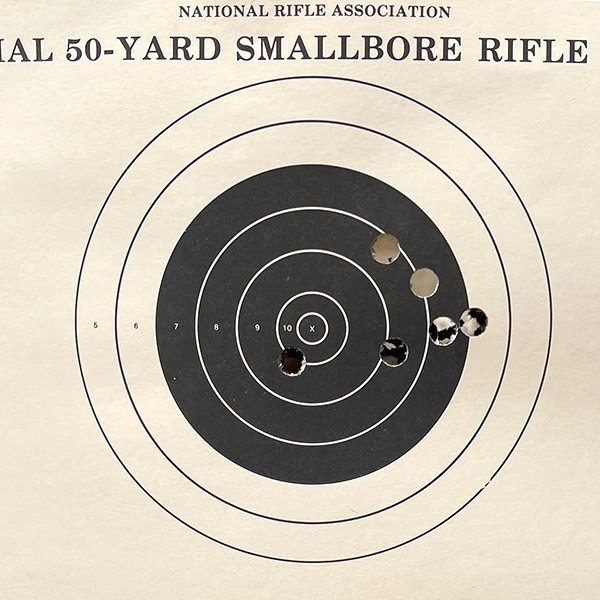

The next day I was on the range at the West End Gun Club. I’d been reading more forum posts about 158-grain semi-wadcutter bullets in .35 Whelen and the feel I got from them was that most people were shooting at 25 yards. You know, turning a grizzly bear rifle into a close-range gopher grabber. Okay, that’s an old reloaders trick: You want tighter groups, just move the target closer. So for the first six of my 19.3-grain Trail Boss loads, I shot at a 25-yard target and wowee: Finally, a group!

It wasn’t a great group (I’ve shot tighter groups at 25 yards with a handgun), but it was a group. It was a clear indication I was on to something. So I next set up a target at 50 yards.

That group was gratifying. I can’t explain the one flyer off to the right (the trigger broke cleanly on that shot and it felt like it should have grouped with the others…maybe it hit a fly on the way to the target). The other five shots went into a group about the size of the bullseye, but biased to the right. That’s one thing I noticed with all of these light loads: They shoot to the right.

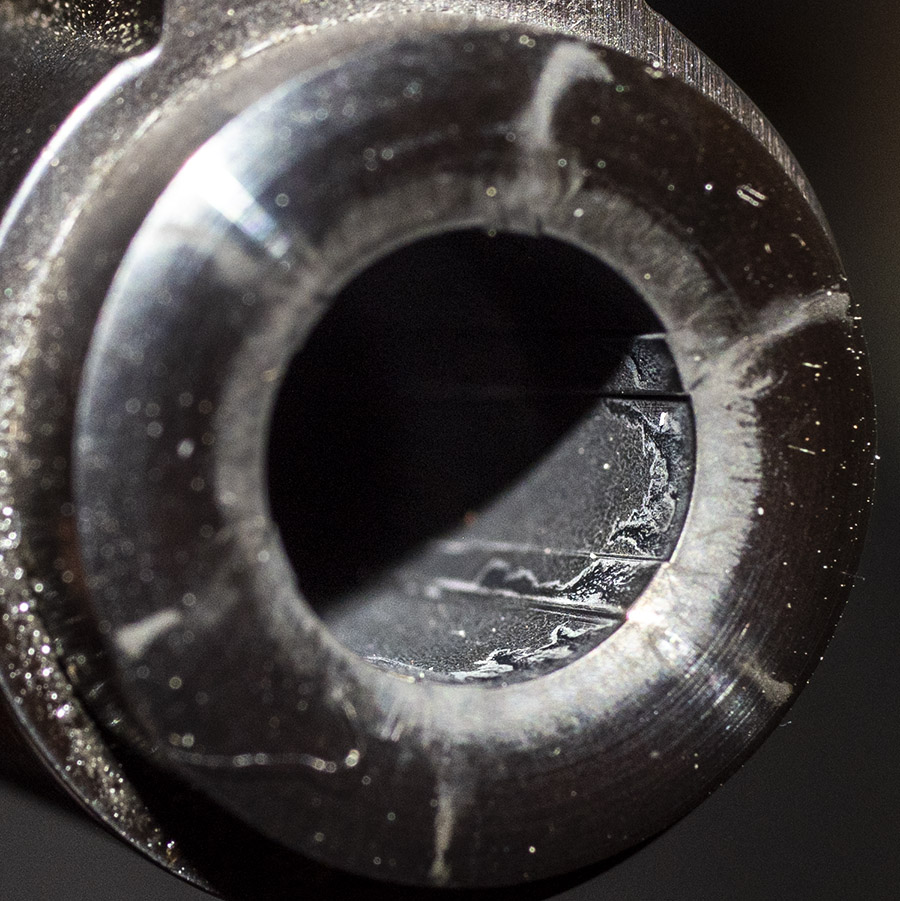

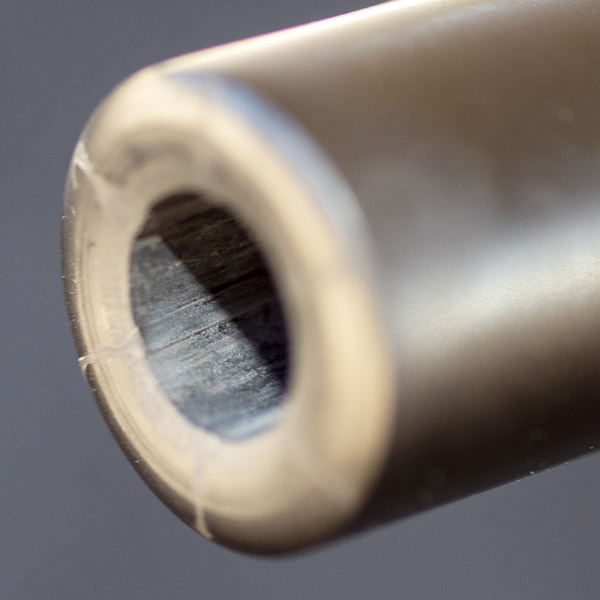

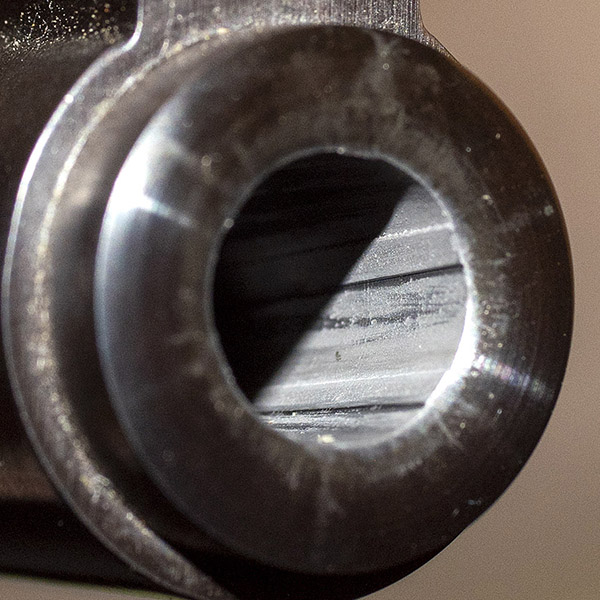

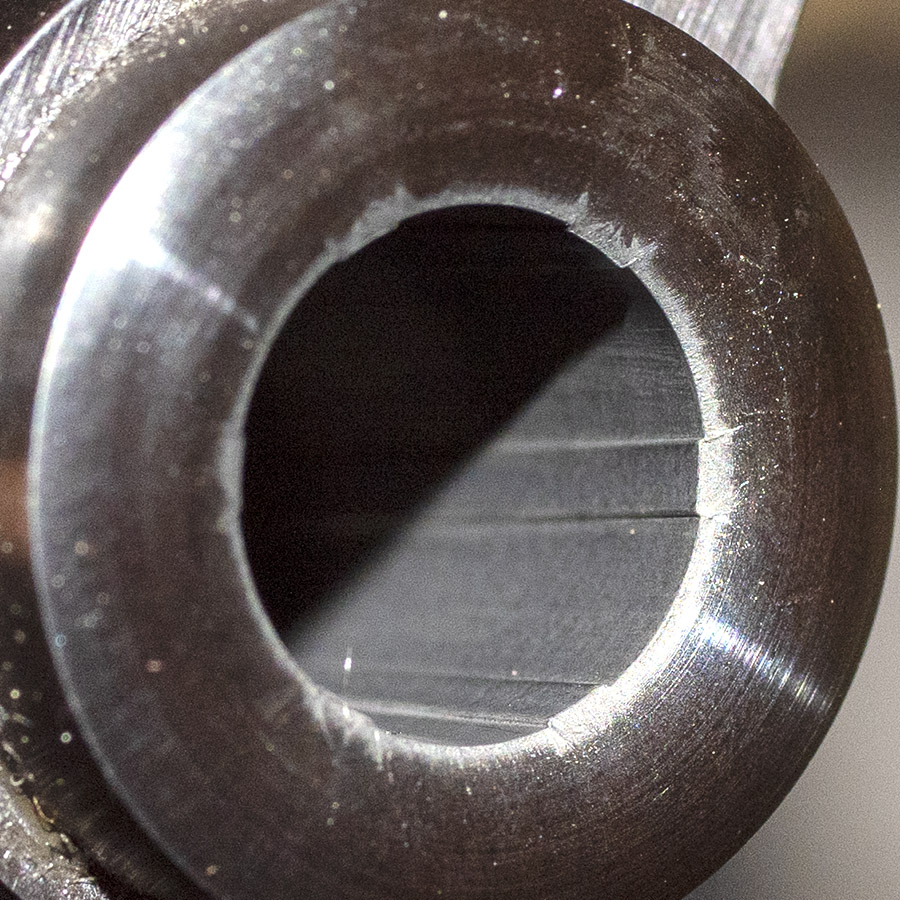

When I returned home, I photographed the muzzle. It’s the photo at the top of this blog. I was pleased to see how clean it was. It had the same appearance as occurred before with 13.0 grains of Trail Boss. There was a kind of swirly thing going on near the muzzle inside the bore; I think that is a combination of melted lead and powder-coating paint behind the bullet as it exits the bore. The rifling was clean, as in no lead.

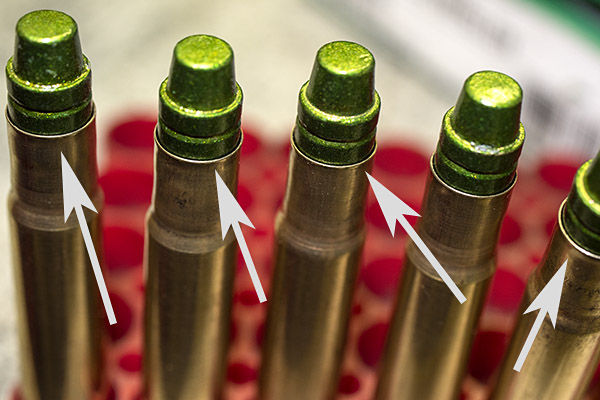

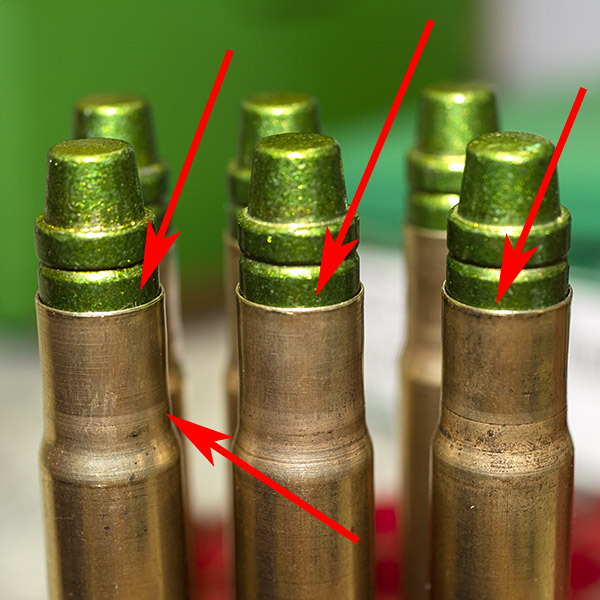

There are a few more things I should mention: When you’re loading at these reduced levels, the brass doesn’t really expand or stretch. Neck sizing works just fine. Also, when you’re loading cast bullets, you have to flare the brass case’s mouth (I use a Lee tool for this) so that the bullet can get an easy start into the case. If you don’t flare the case, you’ll shave the powder coating and lead off the sides of the bullet, both of which will degrade accuracy. And one more note…you’ll see in these photos that I seat the bullets pretty far out for an overall cartridge length of 2.910 inches. The bullets are not contacting the rifling at that length, and there’s enough of the bullet in the case to keep it aligned. I’m not worried about setback (the bullets moving under recoil) because the Ruger No. 1 is a single-shot rifle.

After I seat all the bullets to the correct depth, I then back way off on the bullet seater (again, denoted by the upper arrow in the above photograph). I’ll next screw in the die body (denoted by the lower arrow) until the reduced crimping radius in the die body interior contacts the mouth of the cartridge. At that point, I’ll adjust the die by screwing it in just a little bit further. What I’m doing is adjusting the die so that it removes the flare, but does not crimp the case mouth. You can see the results (i.e., the case mouth flare removed) noted by the red arrows in the photo below.

Back to the cost issue: As you read at the start of this blog, a box of 20 rounds of .35 Whelen factory ammo goes for anywhere between $50 and $72. By my computations, the reloads you read about here cost under $6 for a box of 20 rounds.

So what’s next? Well, the brass is in the tumbler and I’m going to load more. Same load, which kicks about like a .22. Then I’ll try reducing the load slightly to see if that improves things. Stay tuned; you’ll be able to read all about it right here on the ExNotes blog.

More Tales of the Gun!

Never miss an ExNotes blog. Sign up here for free:

Pop up ads. We love ’em. We love ’em even more when you click on them!