By Joe Gresh

I was going to do a bunch of stories on my solar power system that powers my shed. I may still do that but this is more of an update on the batteries I use to store the solar power.

With solar, unless you plan on only having power in the daytime, you’ll need a way to store energy. The traditional way to accomplish this is with lead-acid batteries. I’m a lead-acid fan boy because they are so much cheaper than lithium batteries or a molten salt battery.

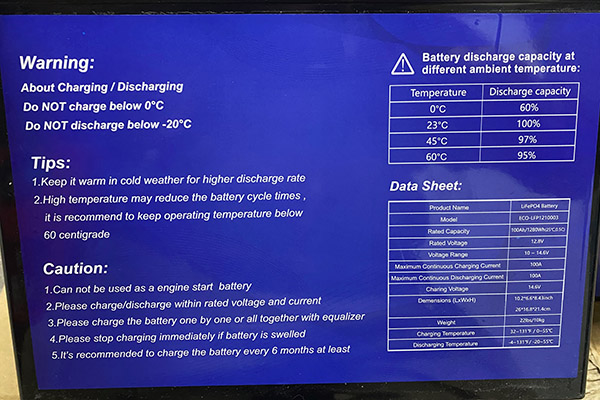

I should say, were cheaper…as of late lithium batteries have been dropping in price so much you can now get a 12-volt 100ah lithium battery for the same price as the cheapest Walmart lead-acid, deep cycle battery.

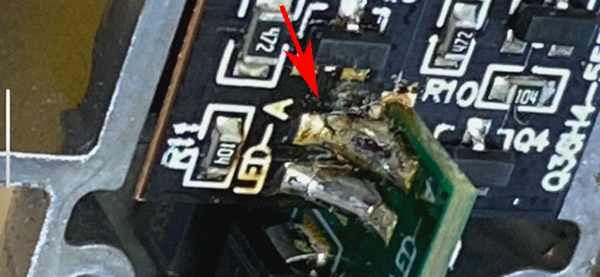

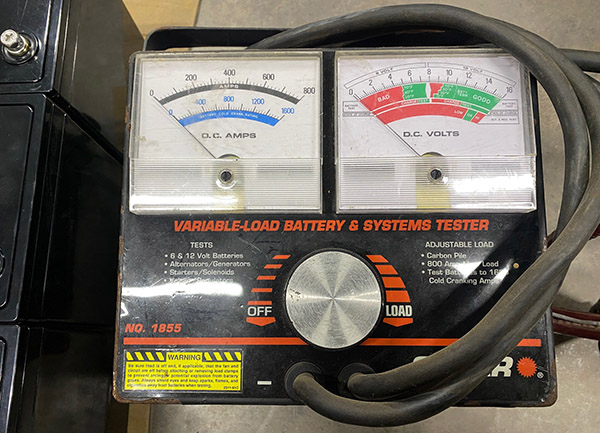

My solar system has been online since 2018 and in those years I’ve had to replace three Walmart batteries. The others are getting a bit long in the tooth, you know? Six years is a good service life for a lead-acid battery. Walking by the battery bank a few days ago I smelled the telltale odor of sulphur. This meant another battery had given up the ghost. It’s usually easy to find the bad battery in a bank. It will be hot to the touch, or in this case the filler caps had blown off. Kind of obvious.

Looking at the average age of my battery bank I decided to bite the bullet and buy a new lithium set up. Getting in just under the tariff wire, so to speak.

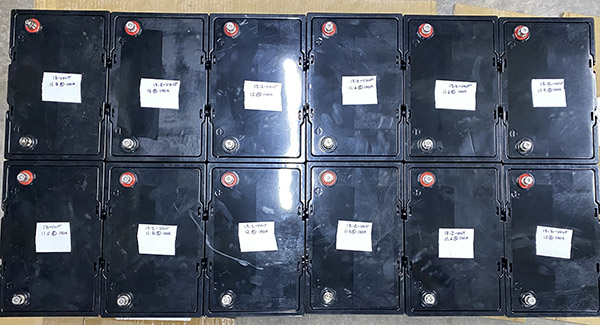

My new bank will be 12, 12-volt, 100ah lithiums. Wired in series/parallel to produce a 24-volt, 600 amp hour storage capacity. That’s theoretically 14,400 watts of storage if you could squeeze every bit of juice out of the batteries.

By contrast, the existing 12, 12-volt 100ah battery bank only has 7200 watts of usable storage capacity due to lead -acid batteries dropping voltage below 50% capacity. The same total amount of juice is in the lead-acids but it’s at a voltage too low to operate equipment.

In addition, the lithium batteries have a smaller footprint so I’ll be able to rig the new bank on a single shelf instead of two shelves like the set up is now. This will cut down in battery cable length and by extension, voltage drop. Less cable is always good with electricity.

All in, I’ll nearly double my solar storage capacity in less square footage for less money than the old style lead-acids. This seems like a win-win.

Now for the downside. These generic lithium batteries claim a 10-year life span but since the Chinese manufacturer’s keep changing brand names like I change underwear the likelihood of the same battery company being around a decade is slim. And then there’s that small detail of the fires.

Lithium batteries don’t like cold weather so that could be an issue. We do get some 20-degree nights at the ranch. I run pipe heaters at night so maybe that bit of drain will keep the batteries snug and warm.

Ah well, it’s not like lead-acid batteries don’t catch fire or explode occasionally.

I’ve had good luck with my Walmart lead-acids, no complaints, and I’m hoping these lithium replacements hold up at least 6 years. 10 years will be great and if they last look for an exhaustnotes long term review in 2035.

Join our Facebook ExNotes page!

Never miss an ExNotes blog:

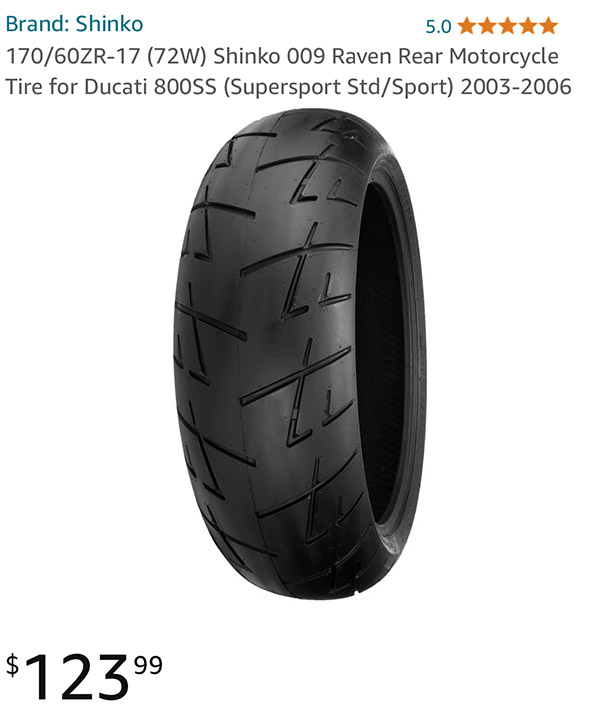

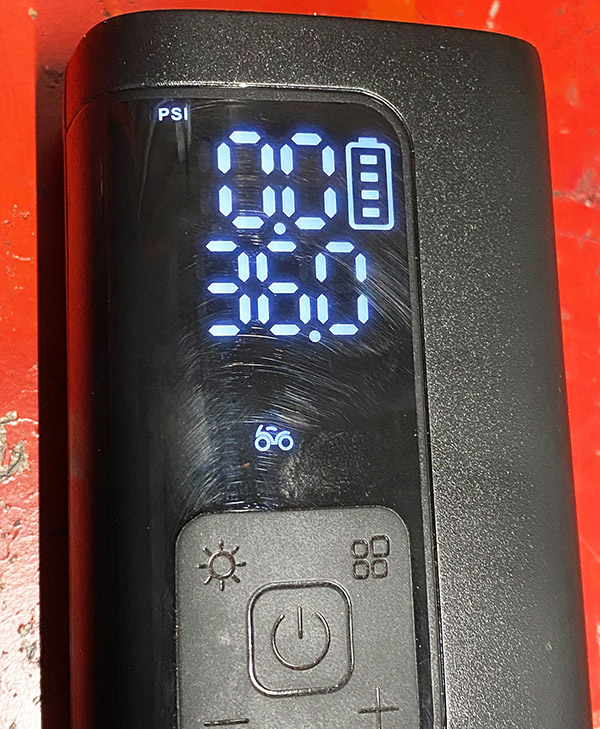

I have a small, 12-volt Slime brand tire inflator that I carry on whichever bike I’m riding. It works well and is like 15 years old now. The main issue (I hate to say problem because it’s more of a design limitation) is that you have to connect it to the motorcycle’s battery. On the RD350 that’s not a big problem but on some bikes, like the ZRX1100, the battery is buried under a bunch of junk I store on the bike. You have to remove the dirty socks, chucks of broken concrete, a dried up Sharpie marker and last year’s Laguna Seca vintage racing schedule. That gains access to the battery door, then you have to slide the battery out to access the terminals.

I have a small, 12-volt Slime brand tire inflator that I carry on whichever bike I’m riding. It works well and is like 15 years old now. The main issue (I hate to say problem because it’s more of a design limitation) is that you have to connect it to the motorcycle’s battery. On the RD350 that’s not a big problem but on some bikes, like the ZRX1100, the battery is buried under a bunch of junk I store on the bike. You have to remove the dirty socks, chucks of broken concrete, a dried up Sharpie marker and last year’s Laguna Seca vintage racing schedule. That gains access to the battery door, then you have to slide the battery out to access the terminals.