I try not to be “That Guy” but sometimes being “That Guy” finds a way. Seven old Yamaha Enduros showed up for the first trail ride of Endurofest 2019 in Flagstaff and the sound of all those cackling dirt bikes was magical. I could listen to that carbon-based music all day long.

Our first stop was a gas station top up. One of the guys knew a short cut through town and we were going to follow him. In all the gassing up and bikes moving around I kind of lost the plot. I took off down the road following a guy on a motorcycle that I thought was one of our group. That bike turned out to be a VStrom Suzuki so I pulled off the road and waited. And waited. Several motorcycles passed by but no smoking old two strokes. I turned around thinking, “Where the hell is everyone?”

I went all the way back to the gas station without seeing the group. I figured I’d make another slow run to see if I could find them and if I couldn’t I would just go for a ride. I caught a glimpse of a bike down one of the side streets and it turned out to be one of our group. He led me back to the gang and they were not exactly glad to see me.

“Rule one: If you don’t know where you’re going, don’t go!” they told me. I felt pretty bad holding up progress and all. I tried explaining how I followed another motorcycle but it was pretty quiet.

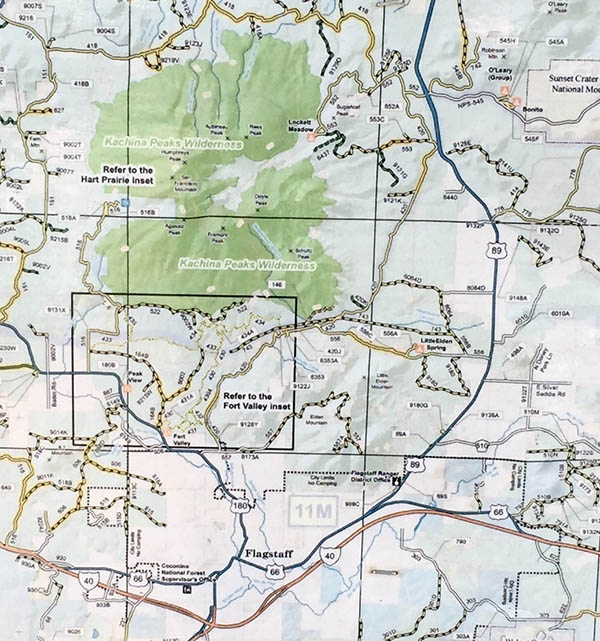

My wing man, Hunter had gone off looking for me. We waited and waited. The thing turned into a cluster and we had not even make the first turn. Once Hunter returned we headed up into the mountains north of Flagstaff. The trails were fairly smooth but you had to stay alert because often a big rock would be in the middle of the trail. Also it was hunting season so a big, lifted pickup truck might be coming the other direction and you don’t want to end up a hood ornament.

With all seven strokers ripping through the woods I’m sure more than one hunter drew a bead on us after we spooked their game.

Don’s 1973, hot rodded 175 Enduro broke its kickstarter stop and the lever was bouncing against the frame making a hell of a racket. He sorted it with a bungee cord.

In areas with trees the shadows on the trail made it hard to see rocks. It all looked like rocks! Hunter nailed one and it knocked the front end sideways. The bike went down and Hunter landed hard.

I was the 4th rider to get there, Hunter was on his knees hunched over cussing so I figured he was ok. We kind of stood around, asking Hunter if he was ok. He mostly just cussed.

“Help me up.” We got Hunter vertical. I knew he was hurt bad because he said we better call an ambulance. I’ve seen Hunter ride one-handed with broken bones through some rough trails. We got the ambulance on the way.

Hunter asked me, “Can you go get my Jeep and take my bike back to the motel?” Another rider, Larry, and I headed back to town. It was a rough couple miles to get to pavement and I was wondering how that ride in an ambulance would feel.

Four-tenths of a mile from our motel Godzilla died. No sputtering, no hint anything was wrong. It was like someone turned off the key. I kicked the bike until I could kick no more. Then Larry have it a few hundred kicks. It was dead. I could see the Motel 6 but to get there I had to push down Prospect Street over to Butler Street. It was a round about way because of all the fences blocking a direct route. I was fairly gassed so Larry pushed me the last few hundred yards.

We got Hunter’s Jeep and drove back out to the crash site. The boys were still there waiting. Hunter uses one of those bumper mounts to tote his motorcycle and with the rough trail we were worried about breaking the thing. Larry decided to ride Hunter’s bike back to the motel as it seemed undamaged.

Everyone made it back safe and sound but Larry said Hunter’s 1975 DT400 handled like crap. It wasn’t until we were loading the bike onto the bumper carrier when we noticed the entire rear section of the frame was broken. Did it happen before the crash, after the crash or on the ride home? We didn’t know but we blamed Larry and said he was riding too fast.

Hunter is in the Flagstaff hospital with 6 broken ribs on one side. I’m not sure how many ribs there are per side but that seems like most of them. We are working on logistics, sorting out how to deal with Hunter’s stuff. Hunter’s wife is flying out to take charge of the situation.

Hopefully the rest of Endurofest will be less exciting.

We never used re-bar caps back when I was doing construction. I don’t think they had been invented yet. It was a different time: You had to be tough, man and I was. If you tripped and fell onto an exposed re-bar the thing would go clean through you and out the other side. The jobsites I worked on were grisly with dead men impaled on rusting steel. I’ll never forget that smell. In the hot Florida sun the bodies bloated fast, seemingly still alive as they twitched and waved a stiff, blackened hand each time a bubble of gas escaped.

We never used re-bar caps back when I was doing construction. I don’t think they had been invented yet. It was a different time: You had to be tough, man and I was. If you tripped and fell onto an exposed re-bar the thing would go clean through you and out the other side. The jobsites I worked on were grisly with dead men impaled on rusting steel. I’ll never forget that smell. In the hot Florida sun the bodies bloated fast, seemingly still alive as they twitched and waved a stiff, blackened hand each time a bubble of gas escaped.

Here’s the thing: my 2008 Husqvarna SMR510 single cylinder thumper has always gotten around 50 miles per gallon of gasoline. Sometimes it does 47mpg, other times 52mpg. These are mostly highway mile ratings because traffic doesn’t exist in La Luz, New Mexico. Rain or shine, for 12,000 miles the fuel usage has been consistent. That’s not bad mileage for a high-strung, near race bike engine so I’m happy.

Here’s the thing: my 2008 Husqvarna SMR510 single cylinder thumper has always gotten around 50 miles per gallon of gasoline. Sometimes it does 47mpg, other times 52mpg. These are mostly highway mile ratings because traffic doesn’t exist in La Luz, New Mexico. Rain or shine, for 12,000 miles the fuel usage has been consistent. That’s not bad mileage for a high-strung, near race bike engine so I’m happy.