By Joe Berk

As mentioned in recent blogs on my 9mm Springfield Armory 1911, I took the gun to TJ’s Custom Gunworks to have it repaired and customized. I have the gun back now and I am very satisfied with the work.

When I took the 1911 to TJ, I asked him to repair the damage I did to my 1911 and to add several custom touches. That’s what he did, and I’ll describe them below. Most of the photos in this blog are from TJ. I took a few, too.

Fortunately, the 1911’s barrel was not damaged (the cartridge blew apart; the barrel and chamber survived). TJ polished the barrel, the chamber, and the ramp. The reinvigorated barrel looks great and it adds to the 1911’s appearance.

TJ polished the 1911’s ramp and chamber. This helps to prevent feed failures and assists in extraction. The polished ramp also helps to prevent bullet pushback into the case as the ramp is pushed from the magazine into the chamber.

The trigger was in bad shape after the 9mm cartridge went into its sudden unintended disassembly mode. TJ cleaned it up, but I’m going to have him fit a new target trigger at some point in the future.

While TJ was in the gun, he removed and replaced the Springfield Armory firing pin and firing pin spring (which he does on all the Springfield Armory 1911s that come into his shop). Springfield uses a titanium firing pin and a heavier firing pin spring, which is a bad combination. I’ve had occasional misfires with my Springfield, and the primers have previously always shown light firing pin strikes. With the new Wilson firing pin and firing pin spring TJ installed, that problem is in the rear-view mirror (where it belongs).

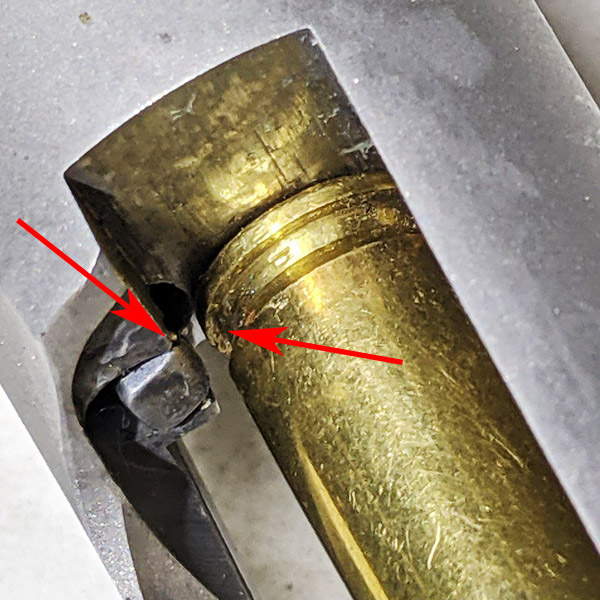

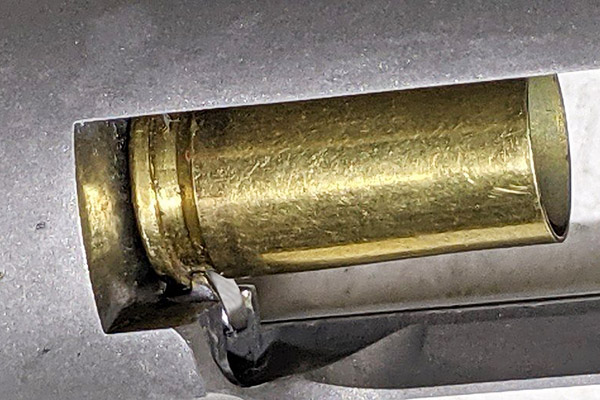

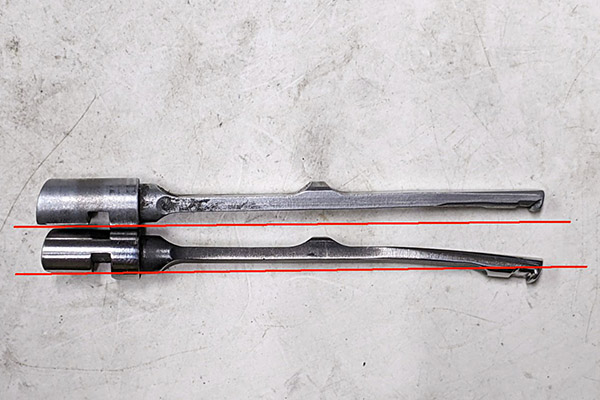

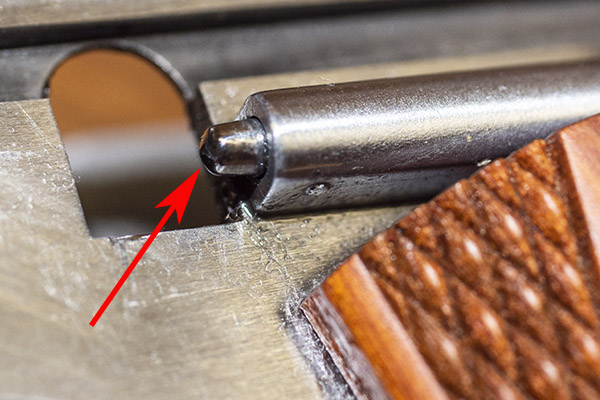

TJ found that the extractor on my Springfield Armory 1911 was terrible. I thought that might be due the base of the cartridge bursting, but it was not. It was just a factory goof up. The photo TJ included shows the extractor about as I remembered it before the event that set all this in motion. The extractor had been extremely difficult to remove from the slide when I disassembled it for cleaning, but I never thought to check if it was engaging the cartridge (the gun had been ejecting). You would think an outfit like Springfield would know what they are doing in this area, but apparently they did not. TJ fit a new extractor to fix that problem.

Ejection is way better now. The gun drops all the cases in the same spot just to my right (they don’t go flying all over creation like they used to). It makes scooping up my brass a lot easier.

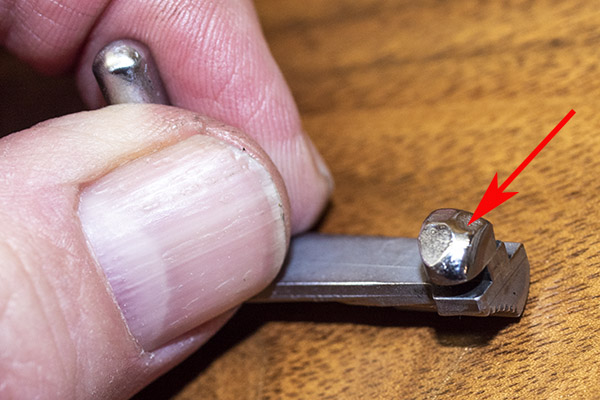

Reinstalling the slide release on my Springfield was difficult. The slide release plunger was too long and the camming surfaces on the underside of the slide release were not cut at the correct angles. TJ reconfigured both. The slide release snaps into place in a very slick manner now. There’s no more worry about scratching the receiver (the so-called idiot scratch) when the gun is reassembled.

TJ polished and fit a new hammer, which looks better than the original. He also lightened the trigger pull. The new trigger is light and I like it.

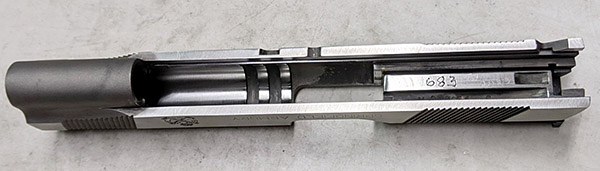

The Springfield Armory 9mm 1911 came from the factory with a two-piece guide rod, which I hated. It would constantly unscrew, even after applying blue Loctite after each cleaning. The stock Springfield guide rod needed an Allen wrench to unscrew and remove it (Springfield provided one with the gun). The gun required doing this to be able to rotate the barrel bushing after depressing the guide rod plug. In my opinion, two-piece guide rods are a solution to a problem that doesn’t exist. I don’t know why manufacturers fit them to new guns and I don’t why anybody would want one. I asked TJ to fit a polished one-piece guide rod to my 1911, and to make it short enough so that I could rotate the barrel bushing for disassembly without having to unscrew the guide rod. I like the new set up a lot better.

Finally, TJ polished the slide-to-receiver interface points. You can see this work in the photos below.

While TJ had the gun, I ordered new grips and a replacement magazine from the Springfield Armory website. The original crossed-cannon cocobolo Springfield grips were damaged when the cartridge burst, so I bought another set (they were reasonably priced at $32.95). The Springfield site also advertised a set of double-diamond checkered cocobolo grips (without the Springfield logo) for $15, so I checked that box, too (I like having an extra set of 1911 grips on hand). The grips and the new magazine arrived a few days after I ordered them.

I picked up the repaired and reinvigorated 1911 from TJ this week. I’ve already been to the range with it and it works well. Watch the blog; I’ll post a range report in the near term. I’ve also had a few more thoughts on what might have caused the burst round that started this adventure, and we’ll have another blog on that as well. Here are links to our prior blogs on this topic:

Thoughts on the 9mm Double Charge

Help us bring more content to you…please click on the popup ads!

Never miss an ExNotes blog: