By Joe Berk

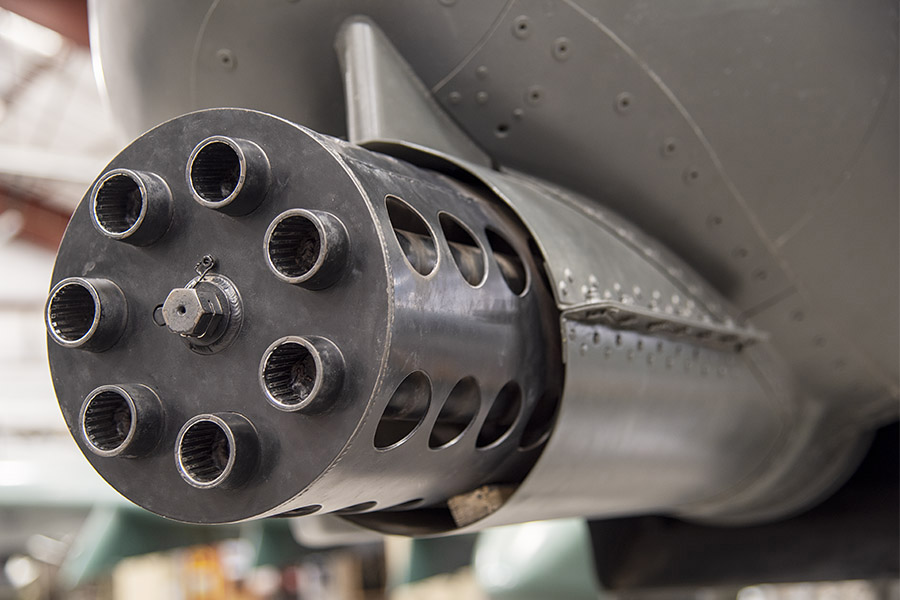

Did you know the original Gatling gun (the Model 1862) used a blackpowder and percussion cap firing system? And did you know that all modern Gatlings (the guns arming the F-15, the F-16, the A-10, the AC-130, and more) are based on the original Gatling gun design? This is a chapter from our book, The Gatling Gun, that addresses the first iteration of Dr. Gatling’s famous weapon. Many of you are blackpowder enthusiasts and I thought you might find the Gatling gun’s blackpowder lineage interesting. I sure did.

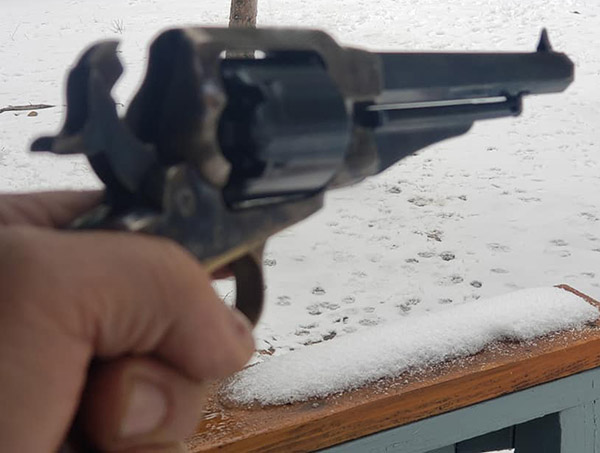

The Percussion Firing System

When most people think of loading a gun, they visualize it as a simple operation in which cartridges are inserted into the weapon (or a magazine). Most understand that the cartridges of modern weapons include both the bullet and the gunpowder. This simplicity of operation was not always the case. Earlier shooters had to use a much more complex percussion firing system. Unlike today’s guns (most of which use metallic cartridges), shooters with percussion firing guns could not simply load a cartridge into their guns and fire. Instead, percussion shooters had to load the primer, gun powder, and bullet into their guns separately for each shot.

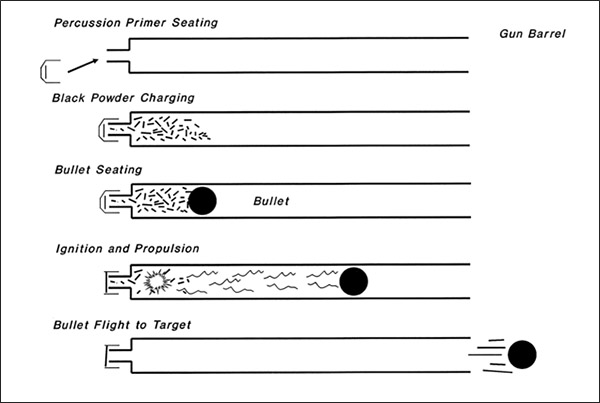

Figure 2 shows the basic elements of a percussion firing system, which consists of a gun barrel and a nipple (the nipple is an extension with a channel).

Loading began by placing a percussion primer on the nipple (as shown in the upper left portion of Figure 2). Black powder was then loaded into the barrel from the muzzle and tapped down prior to installing the bullet. The bullet (usually a round lead ball) was pressed into the barrel, again from the muzzle end (for this reason, percussion weapons are often referred to as “muzzleloaders”). Once the bullet was fully seated against the powder, the weapon was ready to fire.

A percussion weapon was fired by cocking the hammer and then releasing it to strike the percussion cap. The percussion cap contained a small quantity of an impact-sensitive material, which detonated when the hammer struck the cap. This detonation sent shock and heat waves through the channel in the nipple to the black powder. When the black powder ignited, it developed high pressure, which drove the bullet through the barrel with enough velocity upon exiting to continue its flight to the target. As the bullet moved down the barrel, it was engaged by spiral grooves machined into the barrel’s inner surface (these grooves are called “rifling”), which imparted a spin to the bullet. The spin stabilized the bullet, making it more accurate. Once the bullet had left the bore, the spent percussion cap could be removed and the loading and firing process could begin again.

Army Weapon Preferences

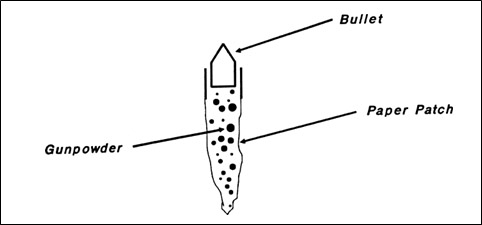

During the Civil War, percussion weapon systems were standard-issue items (even though completely self-contained metallic cartridges had already been invented, the Union army had not yet adopted the concept). A refinement of the percussion priming system that bridged the gap between percussion priming and metallic cartridges had been at least partially accepted by the Union army. It involved the use of integral paper-patched bullets and powder charges. Figure 3 shows the paper-patched bullet and powder concept. Paper-patched bullets and powder charges were loaded as a single unit into the muzzle of the gun (thereby eliminating the need to carry and load bullets and powder separately). When a gun loaded with these cartridges fired, the percussion primer gas jet perforated the paper bag attached to the bullet to ignite the powder. The gun then operated in the same manner described earlier.

Gatling recognized the futility of proposing a gun with metallic cartridges to the Union army and therefore opted to develop his first Gatling gun with paper-patched bullets and powder charges. He developed the first Gatling gun in 1862, accordingly designating it the Model 1862. It was to be the only variant of the Gatling gun that did not use the more modern metallic cartridges, and because of that, certain features of its operational sequence differ from later models. Nonetheless, its operation is worth studying, as it provides insight into the mechanical genius behind the weapon and a fundamental understanding of the operational concepts behind all future Gatling guns (including those used in many of today’s modern weapon systems).

Gatling Gun Operation

As the above description demonstrates, the loading and firing of percussion weapons was a slow and cumbersome operation that left the gunner essentially defenseless during the reloading operation. This disadvantage was primarily responsible for the advent of metallic cartridges. The complexity of the reloading process was also a major design challenge in developing a high-rate-of-fire weapon, as were the cocking, hammer release, and recocking actions. The elegance of the Gatling gun design is that the steps involved in loading and firing occur automatically. To understand how this occurs, one must first be familiar with another important mechanical concept, the principle of the cam.

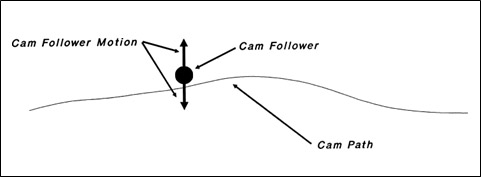

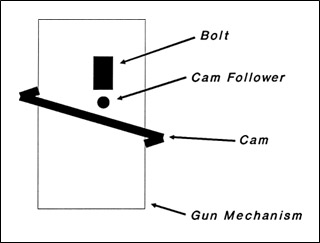

A cam is simply a device that translates motion in one direction into motion in another direction (see Figure 4). It involves the motion of an inclined surface, which is then used to drive a follower. If the inclined surface is wrapped around a rotating surface, the rotating element can be used to create a back-and-forth (or reciprocating) motion in the follower. This is the concept Dr. Gatling used to drive the mechanism of the Gatling gun.

The problem Dr. Gatling solved was generating the reciprocating motion required to step through the actions of firing a gun. This cam-driven concept is shown in Figure 5, wherein the position of the gun mechanism is shown at successive stages of the firing process. In the first position, the gun drive mechanism is near the most narrow portion of the inclined cam surface.

Note that there are two ways a cam can be used to create reciprocating motion: the cam can be driven to actuate the followers, or the followers can be driven while the cam is held stationary. Dr. Gatling chose the latter approach, for reasons that will soon become obvious. As the gun mechanism moves with respect to the cam, the hammer is pushed back, compressing a spring and cocking the gun. When the hammer is fully rearward (and its drive spring fully compressed), it encounters a sharp step on the cam profile. The cam step is a release, and it allows the drive spring to snap the hammer into the percussion cap. This fires the gun.

In our discussion above (and in Figure 5), we depicted a stationary cam surface, as well as a gun barrel and firing mechanism that moved with respect to the stationary cam. It involved a flat cam surface and a lateral motion of the gun along this surface. Let’s take this one step further. Suppose the entire gun mechanism (moving gun barrel and action and cam) is wrapped around a shaft parallel to the gun barrel (as shown in Figure 6). The barrel, hammer, and other elements of the gun’s action would then revolve around this central axis. Suppose further that the cam is wrapped around the interior of a stationary cylindrical housing at the rear of the gun. We’d then have a design in which the gun barrel and action spun around, and the action was driven through the firing steps by the stationary cylindrical cam inside the rear housing. While completing its journey around the inside of the housing, the cam would cock and release the hammer, just as described earlier.

Once the gun operation and rotary gun mechanism/stationary cam concepts are understood, the remaining theory of the operation of the Gatling gun is straightforward. All that’s involved are the additional actions required to load the gun prior to firing and eject the spent cartridge after firing.

The design need not be restricted to only one gun action and barrel. Other actions and barrels can also mount on the central axis, and these can make the circular journey around the stationary cam simultaneously. The number of additional actions and barrels is constrained only by size (how many will fit around the axis and the stationary cam) and weight (if the gun design is limited to a specified weight). The first Gatling gun (the Model 1862) had six barrels, but it could just as easily have had more or fewer.

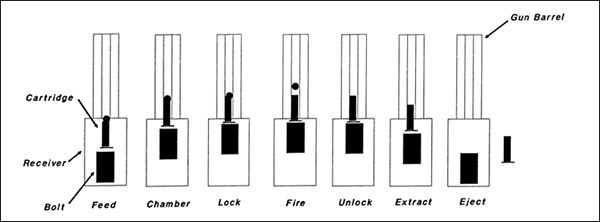

To simplify our discussion, let’s follow the path of one barrel and action around the circular cam. The Model 1862 operated with five basic steps:

• loading

• compression

• locking and firing

• unlocking

• ejecting

Each step occurred as the Gatling gun mechanism revolved inside the stationary, circular cam path. The mechanism was driven by the familiar small hand crank at the rear of the weapon. When the crank was turned, a small pinion gear on the end of it engaged a larger ring gear on the cluster of gun barrels and actions. This large ring gear was fixed to the main shaft of the gun. When the main shaft rotated, the entire barrel assembly and all of the other moving parts (each barrel’s actions, etc.) rotated counterclockwise (as viewed from the muzzle end). As these components moved, followers in each barrel’s action followed the circular cam path in the stationary rear housing.

Loading

At the beginning of this chapter, we described how a basic percussion-fired weapon operates and then progressed into an explanation of paper cartridges. As you will recall, the first steps required placing a percussion cap on the nipple and a paper cartridge and bullet in the barrel. Gatling recognized that these actions could not be easily accomplished while the gun mechanism he envisioned was spinning around a circular cam path. It would be difficult to ram paper cartridges into a spinning barrel and delicately place the percussion caps on moving seats. Gatling solved the problem by preloading steel chambers with paper cartridges, bullets, and percussion caps, and then loading these into the Gatling gun feed mechanism.

These preloaded steel chambers have been described as miniature guns. In a sense they were, but they could perhaps be more accurately described as predecessors to the metallic cartridge. They were self-contained units with a projectile, propellant, and primer, invented solely to simplify loading. Metallic cartridges were smaller and easier to load, but the concept was nearly identical.

The Model 1862 Gatling gun had a small hopper on top of the gun mechanism (near the rear). A quantity of the preloaded steel chambers was placed into the hopper, and as the gun mechanism turned, the chambers fell into grooves in the gun’s rotating mechanism. The gun had a grooved slot for each barrel. When each groove passed approximately through the two o’clock position, one of the preloaded chambers from the hopper dropped into place. The groove aligned the preloaded chamber with the bore of the gun barrel so that when the chamber fired, the bullet had a straight shot into the barrel. As the gun mechanism turned, each preloaded chamber traveled with its barrel, remaining in constant alignment with it.

Compression

As the gun mechanism continued to rotate, a protrusion on the hammer engaged the cam surface. At this point, the lock cylinder actuated. The lock cylinder consisted of a tube containing a hammer and a compression spring. A protrusion on the hammer extended through a groove in the lock cylinder tube to contact the circular cam path. As the gun mechanism continued to rotate, the hammer spring approached full compression (near the twelve o’clock position).

Locking and Firing

Just prior to reaching the twelve o’clock position, the rear of the lock cylinder contacted a small raised surface in the rear of the housing, formed by a hardened steel insert in the plate behind the gun mechanism. The insert was designed to force the lock cylinder forward, which in turn forced the preloaded chamber against the rear of its gun barrel. This caused the forward surface of the preloaded chamber to bear down against the barrel, “locking” it into position and forming a better seal. The concept was to effect a better seal, thereby minimizing the escape of propellant gases and providing for higher bullet velocity.

As soon as locking occurred, the hammer protrusion (in the locking cylinder) reached a sharp forward step on the cam surface, which released the hammer. The hammer spring drove it into the percussion cap, firing the preloaded chamber.

Unlocking

Once the barrel had fired, it had to be unloaded so it could be reloaded and fired again. Before this could be done, though, the locking action had to be unlocked. This was governed by the proper sizing and positioning of the small insert described above. Once the lock cylinder passed the insert (as the gun mechanism continued to turn) another spring on the outside of the cylinder pushed it slightly to the rear. This relieved some of the pressure holding the preloaded (and now fired) chamber against the barrel. The remaining force holding the chamber against the gun barrel came from the hammer spring, which now (in the fired position) held the hammer against the percussion cap and the chamber against the barrel. Dr. Gatling included another small raised surface on the cam path to back the hammer away from the steel chamber just enough to allow the chamber to float freely. This occurred as the gun progressed from the eleven o’clock position to the ten o’clock position.

Ejection

The chamber could be ejected once it had unlocked. This occurred as the rotating cluster of barrels and actions positioned the now-fired chamber near the bottom of the gun. The chamber simply fell free through an opening in the base of the mechanism, where it could be picked up for later cleaning and reloading. To prevent the chambers from getting hung up in the gun mechanism, a guide bar forced them out as the chamber groove passed through the six o’clock position.

Once the five steps described above were complete, the now-empty chamber groove (in the rotating cluster) continued its circular journey up to the hopper, where a new preloaded chamber fell into position and the load, compress, lock, fire, unlock, and eject process began again. As mentioned earlier, the Model 1862 Gatling gun had six sets of barrels, actions, and grooves. These spun as a set, with each of the steps described above occurring sequentially. The gun fired six times with each rotation of the barrel cluster.

The Model 1862 was the only Gatling gun to use the separate preloaded chambers. There were several problems inherent to this approach, which were corrected in subsequent versions of the gun. These problems and others (as well as the solutions and subsequent Gatling guns) are discussed in the next chapter. The use of metallic cartridges in the Model 1865 significantly changed the manner in which the Gatling gun operated. Though many of the detailed mechanical actions changed, all were actuated through the rotating-barrel-cluster and stationary-circular-cam approach. As will be seen in subsequent discussions on contemporary Gatling guns (starting with Chapter 6), all modern variants of the Gatling use this approach.

Want to learn more about the Gatling gun, both the early versions and the ones that arm today’s high performance military systems? Hey, for just $12.95, we can help you with that!

Never miss an ExNotes blog: