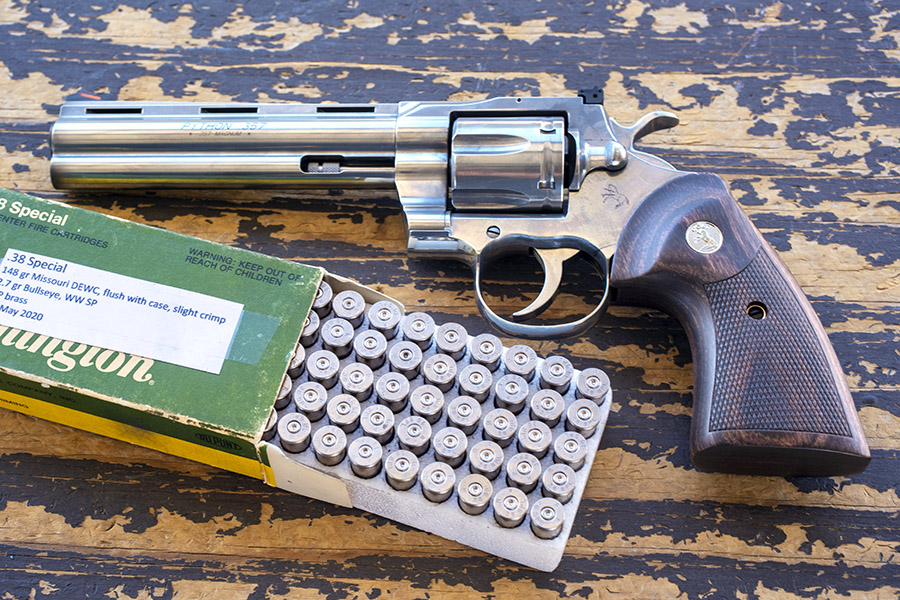

The Colt Python is an iconic handgun that stands out as the pinnacle of the gunmaker’s art. They were originally offered by Colt as their premier .357 Magnum revolver in a run that spanned decades and offered several variants: Blue steel, nickel-plated steel, brushed stainless steel, bright stainless steel, and barrel lengths of 2 1/2, 4, 6, and 8 inches. For a brief period, they even offered one chambered in .38 Special only. That all ended a few years ago when the revolver market subsided and black plastic, semi-auto 9mm gangbanger guns held sideways took over the silver screen (there’s absolutely no accounting for some folks’ taste, I guess). Then, in a surprise move, Colt introduced a re-engineered Python last year, in stainless steel only, with either a 4 1/4-inch or 6-inch barrel. I had to have one, and about a month ago, I scratched that itch.

The new Python carries a hefty $1499 price tag and they are just about impossible to find. And when you do see one, it is always substantially above MSRP. I don’t see the prices coming down on these guns, either. The original Pythons sell for $3K or more (mostly more), and with guns in high demand now and for the forseeable future, I think you’ll always always be able to get your money out of a Python if you ever wanted to sell it. I don’t see the prices going anywhere but up, and like I said, it is near-impossible to find a new Colt Python. But I know people in high places, I got a hell of a deal on my Python, and I am enjoying it enormously. Just looking at it is fun.

I went to my gun club a few days ago to shoot the new Python for the first time, and in a word, it was spectacular. I’ll get to that in a second.

One of the reasons Colt stopped making the original Pythons a few years ago is they were too expensive to manufacture, as they required too much hand fitting of the revolver’s internal components. Colt’s re-engineering effort made all but one internal part capable of being CNC-machined to final dimensions, and in the modern Python hand-fitting is required for only one component. What that did was dramatically improve the double action trigger pull, and somewhat degrade the single action trigger pull. The double action trigger is short and sweet, and the hammer travel is only about half what it used to be. The single action trigger pull is, well, different. Read on, my friends.

Help us keep the content coming: Please click on the popup ads!

Single action, by design on the new Python, has a some take-up and you can actually see the hammer move a little further to the rear when you squeeze the trigger shooting single action. Think of it as a single action trigger that adds a little bit of double action to the dance before it releases the hammer.

I thought there was something wrong with the revolver, but my contact at Colt told me the new Pythons were designed that way to meet the California and Massachusetts drop test requirements. It is definitely not a “breaking glass” single action trigger; it’s closer to pulling the trigger on a Glock (that’s not intended to be a compliment). Double action, though, is absolutely outstanding. It’s a shorter pull than any other double action revolver I’ve ever fired and I like it. I suppose some people might think it’s a good thing that the gun meets the drop test requirements of left-leaning governments. Me? I’d go with Door No. 1 and refrain from dropping my loaded $1499 revolver.

Anyway, the single-action trigger threw me for a loop, but I adjusted to it quickly during a dry firing session. I don’t notice it anymore, and as you’ll see below, it sure hasn’t hurt accuracy.

Fit and finish on the new Python are top notch. You can see that in the photos on this blog, which I shot during and after an extended range session. I probably should have taken pictures before I fired the new Python (when the gun was factory immaculate), but hey, it is what it is.

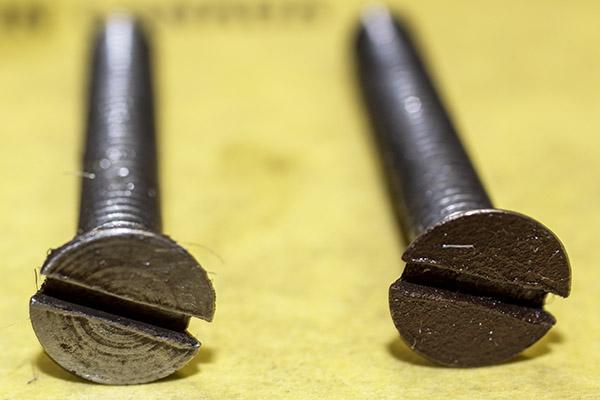

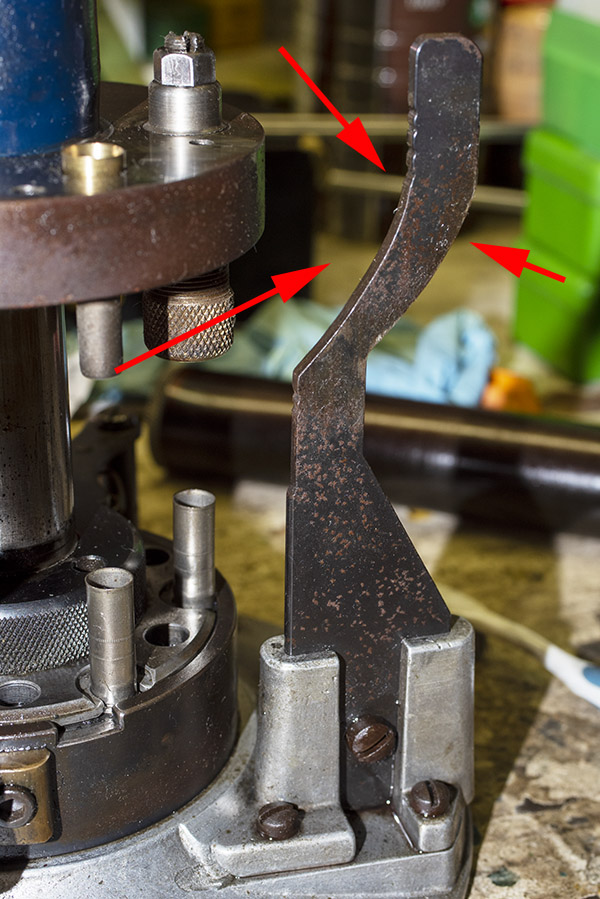

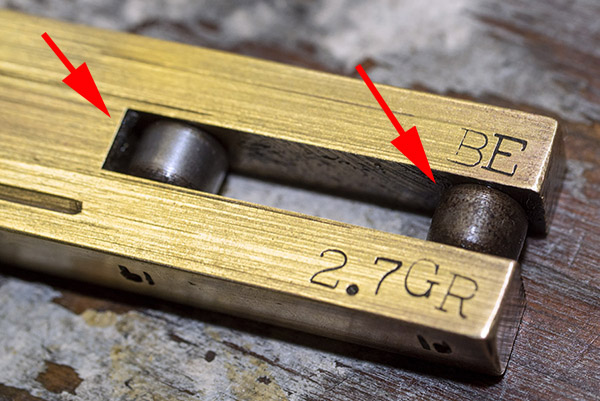

My first shots were 50 rounds I put through the gun using my standard .38 Special target load (2.7 grains of Bullseye and a 148 gr wadcutter, loaded on my Star reloader), all fired single action. I shot from the 50-foot line and it was windy as hell. I had to stop a few times to walk downrange and add more staples to the target because it was starting to come loose, and the target stand was swaying toward and away from me as the wind rocked it. I was shooting, literally, at a moving target.

I was surprised (and pleased) at how stunningly accurate the new Python is. I hadn’t touched the sights, and it was punching holes right where I wanted right out of the box. It put an entire box of ammo into the bullseye with a standard 6:00 hold and the sights left as they came from the factory. That’s a first for me, and I’ve been doing this a long time. The bottom line: The new Python is accurate.

Then I shot another box of 50 cartridges (using the same .38 Special target load I used for the target above), but this time shooting double action. Let me make the point again: These two boxes were the first time I ever fired the new Python. Here’s my second 50 rounds on the target, fired double action.

Eh, one shot went out of the bullseye (it’s that one in the 9-ring, just outside the 10-ring, on the right). Like I said, it was windy out there. But still, for me, this was phenomenal double action shooting. It’s the best I’ve ever done shooting double action, actually.

Then I thought I’d try two 5-shot groups on the 50 foot standard pistol target with .357 ammo (all targets shown here were shot at 50 feet). As you know, a .357 Magnum handgun can shoot either .357 Mag ammo or .38 Special ammo. I brought along some of my standard 357 Magnum reloads (15.7 grains of Winchester 296 powder and a 158 grain Hornady jacketed hollow point bullet). This is a load I’ve been using since my Army days and it does well in any .357 Magnum revolver I’ve ever owned. It came from the pamphlet Winchester published in the 1970s for their powders. It performed superbly well in the new Python.

It’s easy to forget how powerful the .357 Magnum cartridge is unless you fire it back-to-back with the .38 Special. The .38 Special is a very manageable cartridge with moderate recoil, especially in a big, heavy, 6-inch handgun like the new Python. When I shot the .357 Magnum loads, I was instantly reminded that the .357 is a real barn burner. Think big recoil and lots of muzzle flash and blast. It was cool, and the big Python handled full power magnum loads well.

As I already mentioned, it was very windy and gusty on the range (two tractor trailers were on their side on I-15 when I drove out to the club). I was the only guy out there (I’m probably the first guy to visit our range with the new Python, too). On a calm day, I’m sure I could do better than the targets you see above.

I finished up another box of .38 Specials shooting 158 gr cast flatpoint Hursman bullets (also loaded with 2.7 gr of Bullseye), shooting at one of those green star target things you throw on the ground (my daughter bought it for me a few years ago and I think the thing is going to last forever). I walked it out to 50 yards with repeated hits, and I’ll bet I didn’t miss but two or three times out of 40 or so rounds.

There were no malfunctions of any kind in the approximately 150 rounds I fired through the new Python. No light strikes, no misfires, and no jams. And like I’ve been saying, accuracy was stellar. It’s almost like the new Python is laser guided.

You know, there’s an old saying: You get what you pay for. To that, I would add the qualifier: Sometimes. In the case of the new Colt Python, this is one of those times. I love the new Python. It’s an iconic firearm and if you are thinking about getting one, my advice is this: Do so. You won’t be disappointed.

You can see our earlier blog on good buddy Python Pete’s 8-inch, original Colt Python here. And please check out our other Tales of the Gun stories here.

Never miss an ExNotes blog!

Need targets? Order them the way we do and have them delivered to your door!

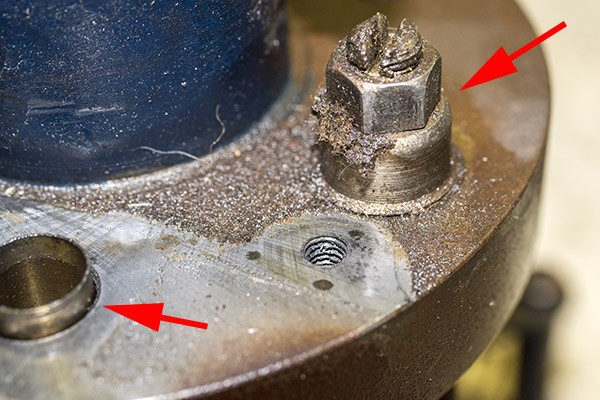

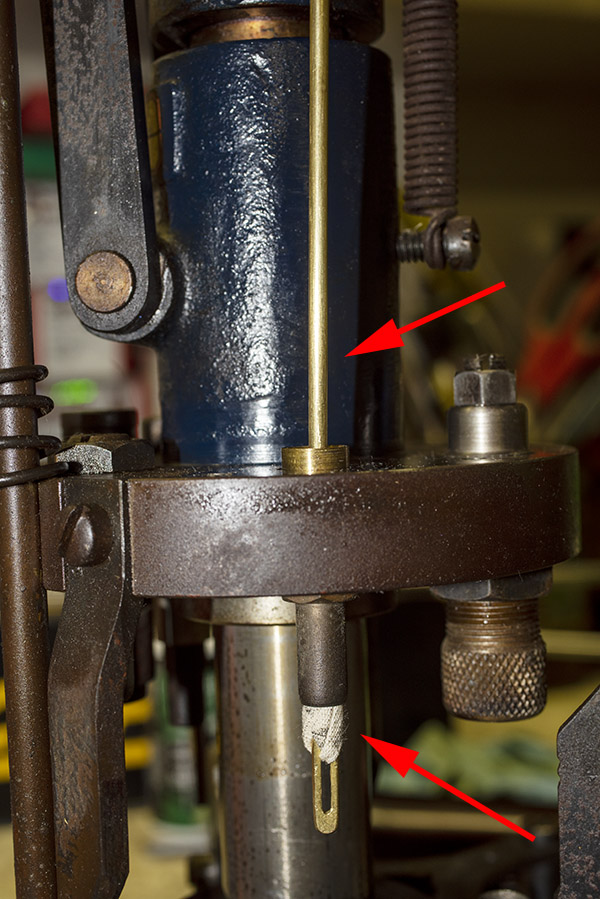

Want to load your own ammo? Here’s a good place to get started in the reloading game!

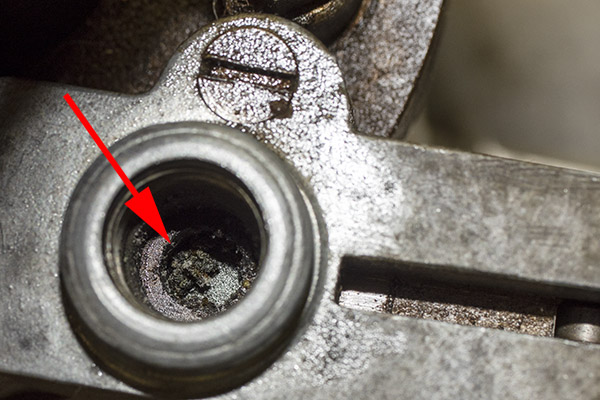

Check out our resurrected Star reloader for prepping high-quality .38 Special ammo!

Want to see more on .38 Special and .357 Magnum accuracy loads in a Ruger Blackhawk? Check this out!

Keep us afloat: Please hit those popup ads!