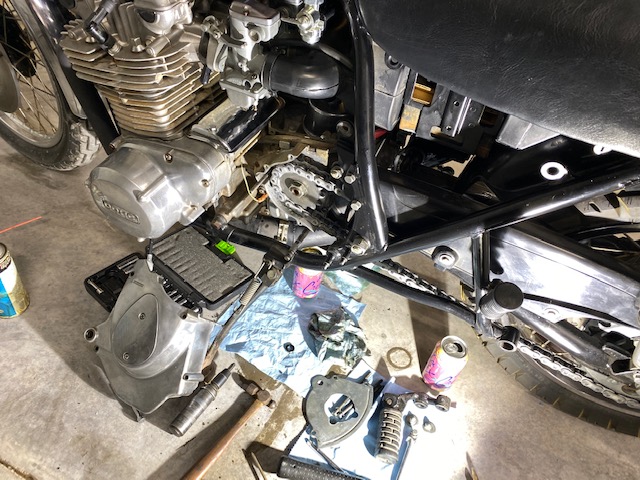

I’ve been watching Berk’s incredible ExhaustNotes content tsunami from afar. The man is amazing, filing stories at a pace that would take 10 or more standard journalists to match. I, on the other hand, have been sleeping until noon and never change out of my pajamas. I managed to avoid getting Covid-19 so far and for a lot of Americans that would be considered success. I’m not most Americans. I want it all so I tore into Zed hoping to stop a few nagging oil leaks that are messing up my nice new concrete floor.

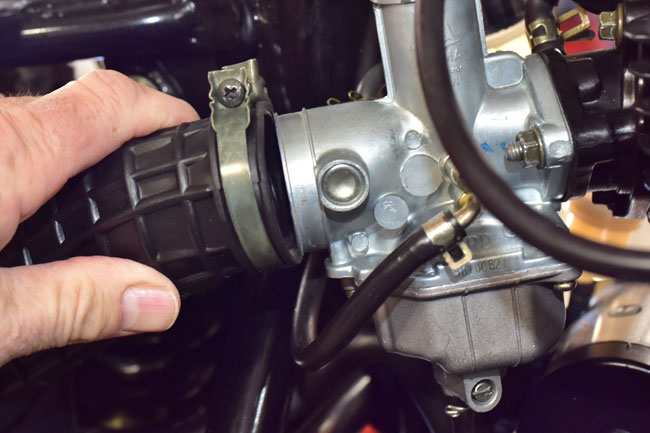

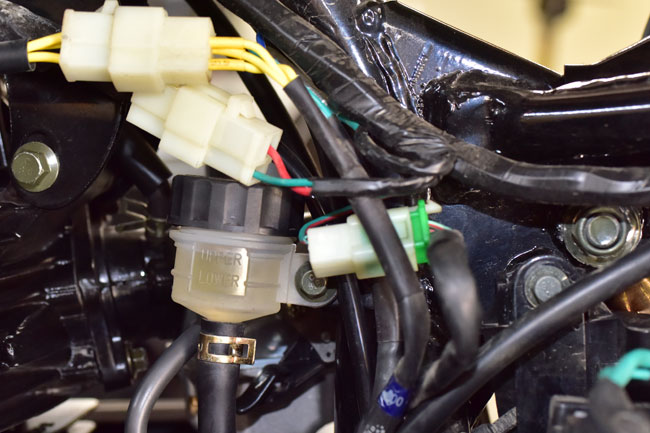

The biggest leak on Zed was the tach drive. And on that part the hardened, dry O-ring was the major source of oil. I dismantled the thing anyway and replaced the shaft seal with a new one from an EBay seal kit. I went EBay for the seals even though my favorite store Z1 Enterprises was cheaper. It was the shipping. The EBay kit was only a $1 more but included free shipping, which made the seal, kit $10 less. Yes, I’m that cheap.

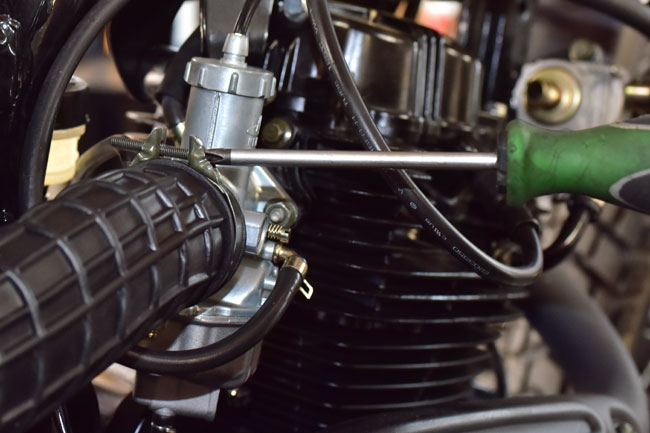

The O-ring had to be gently cut off and it broke into two pieces as the razor knife dug in. For the internal seal I inserted a small screwdriver at an angle and using a small pin punch, tapped the screwdriver until the seal popped out. It wasn’t that tight. Reassembly was a breeze.

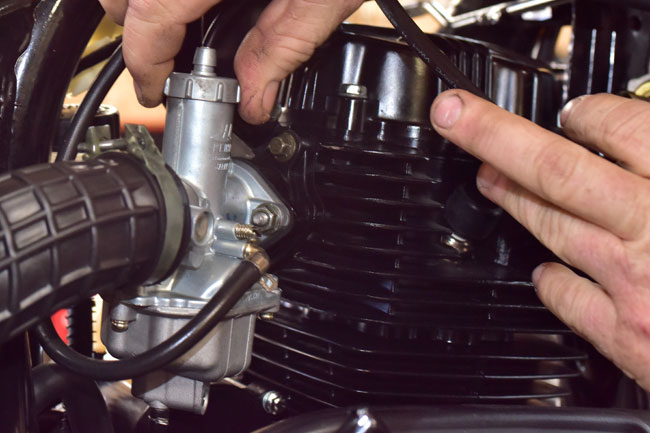

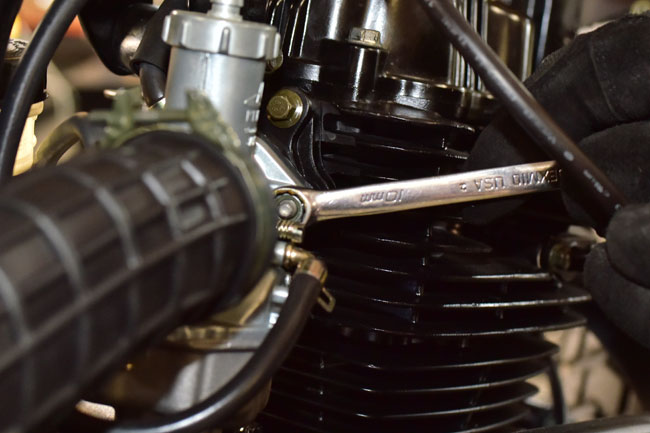

While the leak from the tach drive was dependent on the engine running, a constant drip from the very bottom of the engine was not. It leaked all the time. I traced that leak to the shifter shaft seal. This seal is submerged in oil, hence the steady if unspectacular leak. This leak wasn’t the end of the world as a week’s worth added up to a dime-sized puddle. I figured I had the seal so why not change it?

To do the shifter seal right you really need to remove the countershaft sprocket and the shift ratchet housing. I’m way too lazy to mess with all that, Besides, I didn’t have a gasket for the shifter casting and I didn’t want to create more work. Instead, I used two thin strips of metal and bent short hooks on the ends. The hooks were small enough to fit between the shifter shaft and the outer metal ring of the seal. After jiggling them into place I clamped the ends together with vise grips and used a long paddle bit to lever the seal out of its housing.

It worked so well it caught me off guard. Oil poured out of the shift seal housing onto my nice, new concrete. I rushed around looking for something to catch the mess. Nothing was low enough to fit under Zed’s 4-into-1 headers. Ultimately I cut down an empty kitty litter jug and shoved the plastic tray under Zed. What a mess.

Oil was still dribbling out when I managed to get the seal somewhat started using a short piece of ½” CPVC pipe as a driver. The CPVC pipe wasn’t quite thick enough to make a good, flat push so I drilled a ½” galvanized nut to slip over the shifter shaft and then pounded the nut with the CPVC. That combination made a satisfying thunk when the seal quit moving and the new seal looks seated about the same as the old seal depth wise.

I lost a quart of oil in the shifter shaft mess so I topped up the Kawasaki and after cleaning the floor, ran the bike 5 minutes with out seeing any major leaks. This is good news. The seal changing kit has been taped together and labeled so that when I die anyone going through my tools will know what it’s for.

Time to take Zed out on a run to see what else leaks. I still don’t have a tag because the tag places are closed here in New Mexico. I should have insurance soon. I’m going to bring along the title in my name, proof of insurance and a line of BS for when I get stopped due to my tag being expired 17 years.

There are a few other seals that I’m going to change because they are old. They’re not leaking yet but I plan on taking Zed on some long rides. I figure 45 years is long enough for a seal to last.