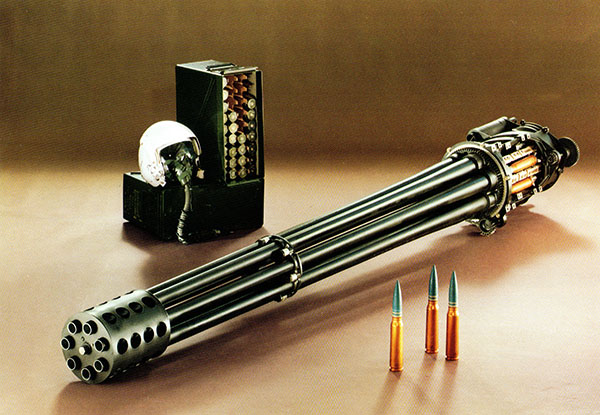

The Gatling Gun, a book that tells the story of the original Gatling guns, their transition to modern gun systems, and several of the weapons platforms currently using Gatlings. It has been one of my most successful books ever. The Gatling Gun

was picked up as the Book of the Month by the Military Book Club shortly after its publication and that made for a very healthy sales spike (and that was okay by me). It seems that every job I had after finishing college had something to do with Gatlings. I was on the Vulcan gun system in the Army. I was on the F-16 design team, an aircraft that flew with a 20mm Gatling. I worked on the Phalanx Close-In Weapon System at General Dynamics here in California. I was the Director of Engineering in the company that manufactured 30mm A-10 ammo. There’s more, but you get the idea.

Writing The Gatling Gun was a hell of a lot of fun, including visits to the Connecticut State Library (where the original Gatling and Colt archives, and many of the early Gatling guns, are stored). I handled original documents prepared by Samuel Colt and Dr. Gatling (and in the process, I became a licensed State of Connecticut historian). It was a hoot.

Of all the modern Gatling-equipped weapons of war, the most powerful is the A-10 Warthog, an aircraft armed with the mighty 30mm GAU-8/A Avenger cannon. Working for Aerojet, the company that manufactured the A-10’s 30mm ammunition, was one of the best jobs I ever had.

Today’s blog includes The Gatling Gun chapter on the A-10. I think you’ll enjoy it.

Chapter 11: The A-10 Thunderbolt Story

As the column of Soviet armored vehicles rolled across the open Eastern European plain, the lumbering sound of diesel engines and clanking treads drowned out all else. Russian infantrymen struggled to keep up, shouting to (but not hearing) each other. Suddenly, a roar different than that emanating from the tanks engulfed everything. It sounded like a powerful internal combustion engine (perhaps that of a race car) running at full throttle. The infantrymen started dropping as the tanks slowed to a stop. From the rear of the column, and working toward the front at an incredible rate, the ground erupted all around in 10-meter-wide explosions. Three of the tanks burst into flames, one blowing its turret off the hull. Black smoke was everywhere. An A-10 passed overhead, its 30mm Avenger gun continuing to roar, throwing out high-velocity depleted uranium penetrators and a 20-foot-long muzzle flash. The aircraft swung low as it passed the column. One of the infantrymen not killed in the first pass realized that the devilish craft was circling for another pass, and in addition to feeling raw terror, he suddenly felt very ill.

Of all the Gatling-gun-equipped aircraft flying today, one of the most intriguing is the A-10 Thunderbolt II. Nicknamed the Warthog by the crews who fly it, the A-10 is the first airplane designed from the ground up around a Gatling gun. It carries the most powerful Gatling gun ever built.

The Close Air Support Problem

The need for the Thunderbolt II and its very specialized mission was recognized during the conflicts in Korea and Vietnam. In these conflicts, U.S. aircraft were the best in the world for air-to-air combat. In the Korean War, these superb fighters included the F-86 Sabre, F-84 Thunderjet, F-80 Shooting Star, and F9F Panther. The F-4 Phantom, the F-111, the F-8, the A-7, and several others saw action in the Vietnam War. Vietnam-era tactical aircraft included such features as supersonic speeds, terrain-following radar, computer-assisted weapon delivery systems, and even such things as exotic as wings with adjustable sweep angles. One problem with these aircraft, however, was that they were designed primarily for air-to-air combat. This made them less than ideal for close-air-support missions (which support ground troops by engaging enemy ground targets). Having been designed for air-to-air combat, they had to be fast and maneuverable, and capable of flying at high altitudes. This placed constraints on the amount and kinds of ordnance that could be carried. Their high speed also meant the airplanes had a high stall speed, which detracted from accurately delivering ground fire.

In the close-air-support role, where the pilot would be required to engage ground targets in close proximity to friendly troops, inaccurate delivery systems were unacceptable. Most of the aircraft that flew in Vietnam were designed with late 1950s and early 1960s technology. During that era, vulnerability to small-arms ground fire was not recognized as a key design parameter. Unfortunately, this is precisely the environment in which close-air support aircraft must operate. In the Vietnam War, more U.S. aircraft were downed by small-arms fire than by any other means. There is even a confirmed case of an F-4 Phantom being shot down by a single rifle bullet.

The most significant drawback of existing close-air-support aircraft (i.e., those used in the close-air-support role prior to the advent of the A-10) was that they were ineffective against tanks. With enemy armor being one of the main threats to NATO forces in the European theater, military planners recognized that an aircraft with new capabilities was required.

The A-X Requirements

The close-air-support deficiencies the United States had observed during the Korean and Vietnam conflicts defined the need for the A-X aircraft in the mid-1960s (A-X stands for “Attack Experimental”). The air force initially envisioned a turbo-prop aircraft. The idea was that a current-technology version of the World War II Thunderbolt would best satisfy the requirements (note that World War II vintage Thunderbolts were used in a close-air-support role in Vietnam). The A-X specification was based primarily on deficiencies in existing aircraft. One of the requirements was an extremely accurate ordnance delivery system, because friendly ground troops could be within yards of the enemy. A high payload was also needed. As explained earlier, most existing tactical aircraft had been designed to maximize either maneuverability, speed, altitude, or some combination of these parameters. Payload had necessarily suffered.

The A-X aircraft also had to be able to remain in the air near the target for long periods of time, which is referred to as “loiter capability.” Existing tactical aircraft had been designed to operate at high altitudes. When flying at the low altitudes associated with close-air-support missions, they consumed excessive amounts of fuel. This translated to short loiter capabilities, which detracted from the effectiveness of close-air-support missions.

The air force also stipulated that the new A-X aircraft needed to have good “survivability” characteristics, meaning it should be relatively invulnerable to small-arms fire from the ground. To ensure that the aircraft met this requirement, the air force specified armor protection, redundant flight-control systems, and fire-suppression equipment.

The Armor Threat

The main requirement for the A-X aircraft, however, was that it be able to contribute significantly to the NATO defense of Eastern Europe, and that meant it had to be able to defeat tanks. (The Soviet Union and its Warsaw Pact allies had tens of thousands of tanks deployed along the East-European frontier. In any European combat scenario, the United States and the nations of Western Europe would have had to be able to defeat these tanks.)

To meet this threat, the United States developed (and continues to develop) many antitank weapons. These include shoulder-fired antitank weapons, large-caliber recoilless rifles, aircraft-delivered missiles and bombs, smart munitions, and several other systems. No U.S. aircraft, however, carried a gun system capable of defeating Soviet tanks.

The Flyoff Competition

In 1967 the U.S. Air Force solicited proposals from twenty-one companies to build a prototype A-X aircraft. After evaluating all of the proposals, it selected Northrop and Fairchild Republic as contenders to enter the final phase of the competition. As part of a new procurement policy, it funded both companies to develop aircraft meeting the A-X specifications. After Northrop and Fairchild finished building the prototypes, the air force conducted extensive tests prior to making a decision. During the competition, Northrop teamed with Ford Aerospace and Communications Company. Ford built the gun used in the Northrop aircraft, which was designated the A-9. Unfortunately for both Northrop and Ford, the Ford gun experienced many problems during the test program, including blowing up on at least one occasion. The antitank gun was the primary weapon for the A-X aircraft, and because the Ford gun (which was also based on the Gatling principle) performed poorly, the outlook for the Northrop A-9 was bleak.

Fairchild Republic teamed with the General Electric Armament Division to build the A-10. The A-10 carried a new 30mm version of the Gatling gun named the “Avenger,” which was based on the older 20mm Vulcan but was much more powerful. When General Electric became involved with the A-X program, it had nearly twenty years of development and production history with Gatling guns of various configurations. This experience was apparent during the test program, and the 30mm Avenger performed superbly. The A-10 rapidly demonstrated that it was a superior aircraft. The prototype flyoff competition ended in late 1972, and the A-10 was selected for a planned production run of 600 aircraft.

The A-10 Thunderbolt II

The A-10 Thunderbolt II is unlike any aircraft in the U.S. inventory. It is quite unconventional in appearance when compared to other tactical jet aircraft, and for good reason. One notably different aspect of the A-10 is its unswept wings. The stubby wings are straight to allow flying at the very low speeds required for the close-air-support role. Another striking difference is the location of the engines, which are mounted high above the rear fuselage. There are two reasons for this. One is better protection from enemy small-arms fire. Another is that the rear fuselage masks the engines’ heat signature, providing better protection from heat-seeking missiles.

The A-10 has many other unique features that are not as readily apparent. One is a high degree of component and subassembly interchangeability. To the maximum extent possible, left and right components of the aircraft are identical, which considerably reduces the number of spare parts needed to support it. The interchangeable components include the engines, landing gear, rudders, and many parts of the wings and tail. The landing gear design is also unique in that when it is retracted, the main and nose wheels protrude slightly beyond the outline of the fuselage. This permits the A-10 to make emergency gear-up landings without damage. The A-10 is designed to survive small-arms fire. Control cables and hydraulic lines are routed so that one projectile could not inflict enough damage to make the aircraft unflyable. Another survivability feature is the cockpit design. The lower portion is surrounded by lightweight titanium armor to protect the pilot. The A-10 payload is quite impressive. In addition to 30mm ammunition, the A-10 can carry missiles, bombs, cluster bombs, and other munitions, for a total of up to 18,500 pounds of ordnance. This is approximately equal to the weight of the aircraft and is about double the payload of other aircraft used in the close-air-support role. Yet the A-10’s most intriguing feature is undoubtedly its 30mm Avenger Gatling gun.

The World’s Most Powerful Gatling Gun

The heart of the A-10 is its 30mm gun. The military designation for this gun is the GAU-8/A (the GAU is pronounced “gow,” and is an acronym for Gun, Automatic, Utility), and the A-10 was literally designed around it.

The GAU-8/A is a seven-barreled 30mm Gatling gun that weighs approximately 3,900 pounds fully loaded (or about 20 percent of the total aircraft weight). The gun is hydraulically driven and is fed through a double helix drum and ammunition feed system similar to that of the 20mm Vulcan (more on the feed and storage system later).

One way to appreciate the power of this gun system is to consider it in relation to the A-10. The gun is mounted to place the firing barrel on the exact centerline of the aircraft, and for good reason. When firing at the maximum rate of 4,200 RPM (it can also fire at a reduced rate of 2,100 RPM), the GAU-8/A generates about 19,000 pounds of recoil. To put this in perspective, consider the power of the A-10’s two fan turbine engines. Each of these generates about 9,000 pounds of thrust. When both engines are at full throttle, they generate a combined thrust of 18,000 pounds, which is less than the recoil of the GAU-8/A. In other words, when firing at maximum rate, more recoil force is generated by the GAU-8/A than by both of the engines operating at full throttle! The effect is quite noticeable, as the gun actually slows the A-10 when it is firing.

The high recoil of the GAU-8/A gun is also the reason the firing barrel is along the aircraft centerline. If it were not, the A-10 would turn away from the target each time the gun fired. Aircraft carrying the 20mm Vulcan in an off-centerline position are also susceptible to this phenomenon, but the recoil of the 20mm gun is small enough to allow for compensation by offsetting the rudder a few degrees. This is normally programed into the flight-control computer and requires no action by the pilot. That approach would not work on the A-10, though. The GAU-8/A gun simply generates too much recoil.

The GAU-8/A Gun System

The GAU-8/A Gun System is made up of four subsystems: the gun, the ammunition feed and storage subsystem, the drive subsystem, and the electrical control subsystem. Specifications for the GAU-8/A gun system are presented in Table 11-1 and explained below.

Table 11-1

GAU-8/A Gun System Specifications

Gun type: 7-barrel Gatling

Ammunition: 30mm HEI, TP, API

Firing rate: 4,200 or 2,100 spm

Gun system weight (loaded): 3,867 pounds

Gun system weight (unloaded): 1,861 pounds

Gun weight: 661 pounds

Drum weight: 780 pounds

Capacity: 1,200 rounds (drum); 1,350 rounds (system)

Drive: hydraulic

Gun length: 112.83 inches

Barrel length: 93.1 inches

Clearing: reverse rotation

Peak recoil: 19,000 pounds

The GAU-8/A gun is a seven-barrel Gatling-based automatic cannon (see the illustrations above). The gun subsystem consists of the following nine major components:

Rotor assembly. The rotor assembly is made up of the forward rotor (which accepts the barrels and is geared to the gun drive shaft) and the mid-rotor (to which the bolt guide tracks are mounted). The rotor assembly operates in the same manner and provides the same functions as that of other Gatling guns.

Housing. The housing serves as the basic frame of the GAU-8/A and provides a mount for many of the gun components (including the lubricator, ammunition transfer unit, solenoid assembly, firing cam,

rotor, and other components). It also contains the elliptical cam path that drives the bolts back and forth.

Barrels. The GAU-8/A has seven barrels. Each is 93.1 inches long and has 20-groove right-hand constant twist rifling (unlike the 20mm Vulcan, which uses a gain twist rifling pattern).

Bolts. Seven bolts are used on the GAU-8/A. They are similar to those used on the 20mm Vulcan, except they are much larger and use a percussion (instead of an electrical) firing system.

Transfer unit. The transfer unit is mounted to the right side of the housing. It feeds ammunition into the gun and accepts fired and unfired cases from it.

Lubricator. The lubricator is mounted on the upper rear portion of the housing. It contains a reservoir of lubricant, and each time the gun fires a small quantity is injected onto the bolt tracks.

Solenoid assembly. The solenoid assembly is also mounted on the housing and is used to withdraw the firing pin safety when the firing signal is sent to the gun.

Mid-barrel support and clamp. The mid-barrel support and clamp provides the forward mounting point for the GAU-8/A. It also locks the barrels in position within the rotor.

Muzzle clamp. The muzzle clamp provides structural support for the cannon and maintains concentricity of the barrel cluster.

Ammunition Feed and Storage Subsystem

The ammunition feed and storage subsystem is used to store and convey live and spent rounds (empty cartridges are not ejected out of the A-10). The nine major components of the subsystem are as follows:

Ammunition storage drum. The ammunition storage drum is similar in concept to the drum used for the 20mm Vulcan. It consists of an inner and outer drum, two scoop-disk assemblies, two drum-cover assemblies, and two spacer rings. The inner drum has a double-helix that forces the rounds forward or backward when the inner drum is rotated. Ammunition passes through the drum-cover assemblies for loading, unloading, firing, and returning fired cartridge cases to the drum.

Entrance unit. The entrance unit is mounted on the rear drum-cover assembly. It receives fired cases from the conveyor elements (explained below) and passes them into the ammunition storage drum.

Exit unit. The exit unit is similar in concept to the entrance unit. It mounts on the front of the ammunition storage drum and is used to feed live rounds into the conveyor elements.

Ammunition chuting. The ammunition chuting provides a path for the conveyor elements that carry ammunition to and from the GAU-8/A gun.

Conveyor turnaround unit. The conveyor turnaround unit feeds live rounds into the gun transfer unit (explained in the description of the gun subsystem). The conveyor turnaround unit also accepts spent rounds from the gun transfer unit and places them in conveyor elements for return to the ammunition storage drum.

Ammunition conveyor elements. The ammunition conveyor elements are linked together to form an endless belt that travels to and from the gun through the ammunition chuting. Each element carries one round of ammunition going to the gun and one spent case or unfired round when returning to the ammunition storage drum.

Drum drive unit. Mounted on the drum exit cover, the drum drive unit drives the ammunition storage drum.

Equalizer. The equalizer is mounted on the ammunition chuting approximately midway between the ammunition storage drum and the GAU-8/A gun subsystem. It equalizes the tension between the feed and return ammunition conveyor elements.

Loading access unit. The loading access unit is used to load ammunition into the storage drum. It is accessible through a panel on the left side of the A-10 (just forward of the wing).

Drive Subsystem

The drive subsystem is a hydraulic drive assembly consisting of the following major components.

Hydraulic drive motors. Two identical hydraulic drive motors provide power for the GAU-8/A gun and the ammunition feed and storage system.

Accessory drive gearbox. The accessory drive gearbox is driven by the hydraulic drive motors. It provides output torque for the gun and drum drive shafts.

Gun drive shaft. The gun drive shaft provides power to the GAU-8/A gun subsystem.

Drum drive shaft. The drum drive shaft provides power to the ammunition feed and storage subsystem.

Electronic Control Subsystem

The electronic control subsystem consists of the electronic control unit. This “black box” contains the circuitry that controls all GAU-8/A logic functions.

System Operation

When the A-10 pilot engages a target, the first step is to bring the armament control system to a state of operational readiness. Once this is done, the pilot must get the target in the Heads Up Display screen,

commonly referred to as the HUD. The HUD is a transparent screen mounted directly in the pilot’s line of sight. A small pipper (or bright spot) is projected onto the screen, and the pilot maneuvers the airplane (and consequently, the GAU-8/A gun) until the pipper is directly on the target. This allows the pilot to engage the target without having to divert his vision. This capability is critically important in a close-air-support aircraft, which must fly at low altitudes.

When the pilot wants to fire the GAU-8/A gun, he presses the control-column-mounted trigger. The trigger sends a signal to the electronic control assembly, which subsequently sends a signal to two solenoids mounted on the hydraulic drive assembly. When these solenoids open, aircraft hydraulic pressure is applied to the two hydraulic drive motors, and the gun, ammunition storage drum, and chuting begin to move. One-tenth of a second later, the electronic control assembly sends another signal to the firing solenoid assembly, which is mounted on the gun housing. This solenoid withdraws the safing sector from the firing cam path in the gun housing, which allows ammunition to begin the classic seven-step Gatling firing sequence. Each round fires as it reaches the firing point.

When the trigger is released, the electronic control assembly sends a reverse signal to the hydraulic drive assembly. The hydraulic drive motors reverse and rapidly decelerate the gun system. The gun system cycles in a reverse direction until all rounds are cleared from the cannon. This is done to prevent a cook-off (the inadvertent firing of a round due to absorption of residual gun heat), which could occur if a live round remained in one of the GAU-8/A’s chambers.

The 30mm Family of Ammunition

The success story behind the 30mm family of ammunition used in the A-10 is as intriguing as the story behind the A-10 and the GAU-8/A. When the air force began the A-X program, the intent was to manufacture the 30mm ammunition in government arsenals. In the past, the government usually bought ammunition components from several suppliers and then did the loading, assembly, and packing operations in a government load plant. In the early 1970s, the government estimated that the cost of each 30mm round would be about $75.

Aerojet Ordnance Company and Honeywell, Inc. (two munitions manufacturers) convinced the government that it would be best to allow private industry to manufacture the complete round. Under this procurement concept, GAU-8/A ammunition production has been enormously successful. Private industry was able to deliver high-quality ammunition at about $6 per round instead of the $75 the government originally planned to spend. To date, more than 80 million rounds have been procured. The 30mm family of ammunition consists of three different rounds, as explained below:

Target practice. The target practice (TP) cartridge is used for training.

Essentially a slug, the projectile has an aluminum nose and steel body.

High-explosive incendiary. The high-explosive incendiary (HEI) cartridge fires an explosive warhead with a point-detonating fuze. The projectile body is made of steel and contains .124 pounds of a high

explosive and incendiary mix.

Armor-piercing incendiary tracer. The armor-piercing incendiary tracer (APIT) cartridge fires what is probably the most intriguing of the 30mm projectiles. The APIT projectile has a depleted uranium

penetrator sheathed in an aluminum sabot. The depleted uranium penetrator has two functions. Because depleted uranium is a very dense metal, it defeats enemy armor through kinetic energy alone (the combination of high velocity and mass allow it to break through armor). Depleted uranium is also pyrophoric, meaning it burns with intense heat after it breaks up. These two characteristics make it extremely effective against enemy tanks. The rear of the projectile contains a pyrotechnic fumer, which reduces aerodynamic drag and allows it to maintain high velocities.

The normal GAU-8/A combat mix of ammunition consists of one HEI round for every five APIT rounds (TP ammunition is used solely for target practice and is not usually mixed with HEI or APIT ammunition). All types of 30mm GAU-8/A ammunition use aluminum cartridge cases (to conserve weight) and either plastic or copper projectile bands (to engage the rifling in the GAU-8/A gun barrels). The projectile bands permit higher muzzle velocity and reduced barrel wear.

The A-10 Bottom Line

All things considered, the GAU-8/A 30mm Gatling gun is one of the most interesting and successful applications of ground-attack aircraft ever developed. The GAU-8/A gun system is the most powerful Gatling gun ever built. The extremely lethal 30mm family of ammunition is an amazing procurement success story. The A-10, the GAU-8/A, and the 30mm family of ammunition still make up an important part of the U.S. national defense and will continue to for quite some time.

So there you have it: Chapter 11 of The Gatling Gun. There are 15 chapters in The Gatling Gun

touching on all of the early Gatlings, their Civil War and Indian war deployments, the transition to modern high-rate-of-fire gun systems after World War II, and contemporary Gatling systems like the A-10 Warthog. If you liked our chapter about the A-10, you might enjoy the rest of The Gatling Gun

.

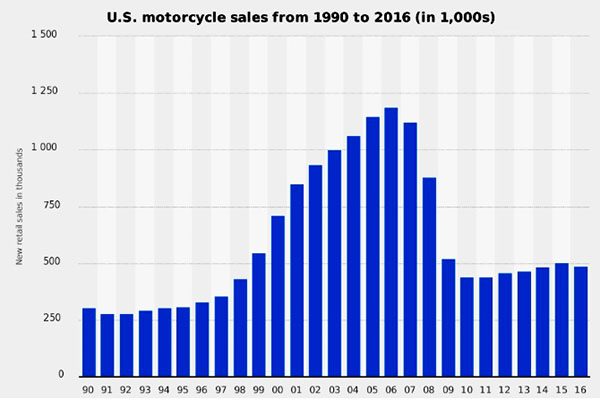

Our most commented upon post last year? It was Joe Gresh’s

Our most commented upon post last year? It was Joe Gresh’s

We’ve stepped on a few toes along the way. Some folks got their noses bent out of shape because

We’ve stepped on a few toes along the way. Some folks got their noses bent out of shape because  We did a lot of travel this year, but not as many motorcycle trips as we wanted. The Royal Enfields we took through Baja were fun, and we had a

We did a lot of travel this year, but not as many motorcycle trips as we wanted. The Royal Enfields we took through Baja were fun, and we had a