I had a hard time selecting the title for this blog. I ultimately went with the one you see above because I think it will show up better on the search engines. But I almost went with Stupid is as Stupid Does (you know, from the Forrest Gump movie). Read on. You’ll see.

I am a big fan of the Ruger Blackhawk, and I wanted to try something different a few years ago, so I bought an older .30 Carbine Blackhawk on Gunbroker. I was excited about getting it, but I have to tell you that revolver had issues, one of which led to its ultimate destruction. One issue was that every case stuck in the cylinder after firing, and the other issue was that the cartridges dragged on the frame and the cylinder wouldn’t turn freely.

I doped out the cylinder drag issue fairly quickly. You have to trim the brass after nearly ever firing, and you have to make absolutely certain the primer is at or below flush after seating (something you should do for all cartridges). The .30 Carbine is a cartridge that is unusually sensitive to all this in the Blackhawk. .30 Carbine cases shrink in length when fired, and then they grow in length when you resize them. The cartridge headspaces on the case mouth so case length is critical, and the .30 Carbine case seems to grow and shrink more than others. Let it get too long, even by just a few thousandths, and the based of the cartridge will drag on the frame and the cylinder won’t turn freely. I learned to check case length every time I reload this cartridge, and I usually have to trim about half of them.

The next issue is primer seating. Even though I clean the primer pockets each time I reload, I found that a handheld priming tool won’t always fully seat primers in a .30 Carbine case. Hey, I’m not looking for an argument here and if you can do this with your hand priming tool, more power to you. I’m telling what my experience has been. I have another priming setup (also made by Lee), and it’s the Auto Prime tool that mounts on the press. It positively seats the primer below flush on every cartridge. It’s what I use now when priming .30 Carbine cases.

All the above is a prelude. I fixed the cylinder drag issue on my first .30 Carbine Blackhawk using the reloading process shown above, but I still had the extraction problem. The cases just did not want to leave the cylinder. The extractor rod was bending and the cases still wouldn’t extract. It was so bad that I usually had to take the cylinder out of the revolver to drive the cases out with a cleaning rod. I tried everything to fix that problem. I polished the chambers and I swabbed them with alcohol to remove any traces of oil (an oily chamber or cartridge case allows brass to flow into any machine marks in the chamber, locking it in place), but I still had the extraction problem.

Then I tried lighter loads. A little bit lighter wasn’t doing it with the propellants I had been using, so I went to Trail Boss (a powder known for working well with lighter loads). That’s how I got in trouble. You have to understand that reloading manuals don’t include data on Trail Boss for many cartridges, and in particular, there was no data in any of the several reloading manuals I own on using this powder with the .30 Carbine. The Trail Boss manufacturer’s guidance is to load to the base of the bullet for a max load, and not less than 70% of that amount as a minimum load. I loaded at just under the max load.

I thought I was doing pretty good when I fired the first Trail Boss load and ejected the case. It extracted easily. This is progress, I remember thinking. Things are looking good. So I fired the remaining four rounds. Then I walked downrange to check the target.

Hmmmm. That’s odd. Not a single shot was on the target. My first thoughts were the load was either terribly inaccurate, or it was so light the bullets were hitting below the target. Then, when I walked back to the firing line, I saw it: A sickening glint of copper peeking out of the Blackhawk’s barrel. A stuck bullet. Five of them, actually. I got a bullet stuck in the bore and didn’t realize it. Then I had fired another, and another, and…well, you know. They liked that barrel, those bullets did, and that’s where they stayed. I felt even worse when I ran my fingers along the length of the barrel. I could feel the swells in its diameter from each bullet to the next. Good Lord, they build Rugers tough (that’s why I’m here to tell this story). Forrest Gump has nothing on me. Like I said at the beginning of this blog, stupid is as stupid does. The weird part to me was that I couldn’t feel anything different when firing the gun.

I was embarrassed and thoroughly disgusted. It was the dumbest thing I’d ever done. When I got home I put the gun in the back of my safe and I left it there for a year. I didn’t want to think about it and I didn’t want to see it. But I knew it was there, bearing silent witness to my stupidity. I wanted to get it fixed, but I didn’t want to admit to anyone I had done something so dumb. The barrel was toast, and the revolver’s frame looked a little distorted to me. Best to just forget about it. Maybe save it for a gun buyback program.

Then one day I figured I had waited long enough, and I called Ruger. I told them my story and the nice lady on the other end told me I wasn’t the first one to call with stuck bullets in the barrel. I felt a little better. I asked if they could re-barrel my Blackhawk. Sure, she said, and off it went. A few days later Ruger called me, and that same nice lady told me a new barrel would be $400.48, but they weren’t too sure about the gun’s structural integrity. Or, they could sell me a brand new Blackhawk. How much would that be, I asked. $400.48, she said. Ah, I get it. What they were really telling me is to buy the new gun at the steeply-discounted price (MSRP on a new .30 Carbine Blackhawk is $669). I was in. Here’s my credit card number. Send me the new gun.

So I received the Blackhawk, but like its predecessor it went in the safe. I still didn’t want to be reminded of what I had done. And, I had managed to convince myself that shooting a 40,000 psi M1 Carbine cartridge in a handgun maybe was just not meant to be. What I was really afraid of was that the new Blackhawk would have case extraction issues like the first one.

Another three years went by, and then something clicked: I woke up and felt like shooting my .30 Carbine revolver. I can’t say why it took three years. It just did. I had the urge and I loaded a box of .30 Carbine ammo in different flavors to test what worked best. And a couple of days ago, we went to the range.

How did it go? In a word, awesome. Take a look:

This new .30 Carbine Ruger Blackhawk revolver liked every load I tested. One was exceptional:

Shooting a .30 Carbine Blackhawk is fun. You get massive muzzle blast, a huge muzzle flash, and major noise (hey, 40,000 psi is 40,000 psi), but little recoil. And, as the above target and load data show, it is accurate. This puppy can shoot.

You know what else? The spent brass practically fell out of the cylinder when I emptied it. The extraction problem is gone. I’m wondering if something was wrong with the first .30 Carbine Blackhawk that caused the pressures to go excessively high and seize the brass cases in the cylinder (the chamber exit bores could have been too small, or maybe the barrel was undersized). I’ll never know, but I don’t care. This new Blackhawk is a honey.

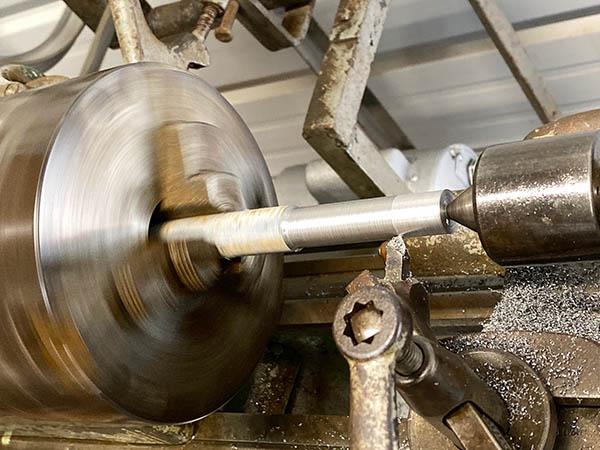

A bit about the gear I use in my .30 Carbine reloading activities. I use Lee dies, although just about .30 Carbine reloading dies will do the trick. I normally stick with RCBS reloading gear, but I could get the Lee dies quicker so that’s what I bought. I like them. Most of my other reloading gear is RCBS, including the RCBS powder dispenser

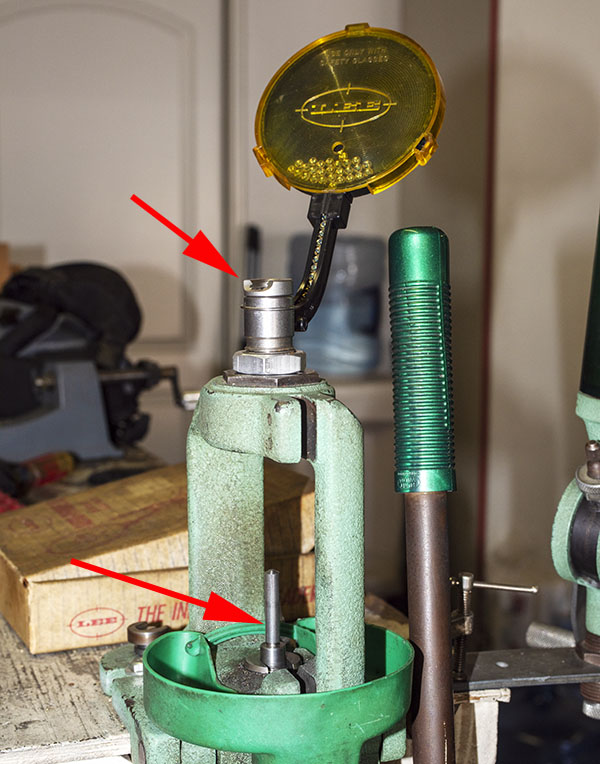

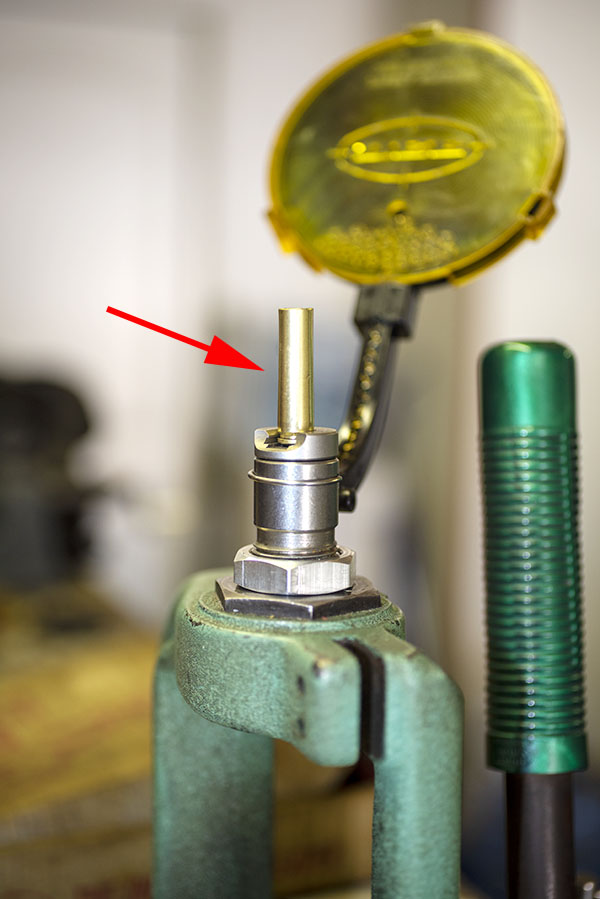

, the RCBS Rockchucker press

, and the scale. Again, any brand will work. In looking at the prices for RCBS gear, I notice that it has become fairly expensive. If you want to get into reloading for a lot less, you might take a look at this LEE PRECISION Anniversary Challenger Kit

. It contains most of what you need except for the dies. Knowing what I know after having been a reloader for 50 years, it’s what I would buy if I was starting out all over again.

Keep us afloat…please click on those popup ads!

More Tales of the Gun stuff? Just click right here!