I recently posted a Wayback Machine blog on riding in the rain, and Carl Bennett (a new friend from the UK) added a comment about one of his rain rides. Carl’s input was interesting on several levels, one of which was the included web address. I poked around a bit on Carl’s site and found a blog post titled “Lobo.” Well, one thing led to another, with the result being Carl’s permission to publish “Lobo” here on ExNotes. I enjoyed reading it and I think you will, too.

– Joe Berk

By Carl Bennett

As a name for a motorcycle it’s okay. It means timber wolf, in Spanish, but maybe that means Mexican. Oooops, I meant Microsoft Spanish, for whom Spanish means Old Spanish. Obviously in global internet land, Microsoft’s 14-year-old-in-Ohio sensibilities reign supreme. Which is a whole other story. And this one is about me. Like all my others, as yours are all about you and Charles Dickens’ were about him. And especially Martin Amis’s were all about him. God, were they about him. I don’t know if he ever had a motorcycle. Hunter Thompson definitely had several, but as he wrote himself, Mister Kurz, he dead.

Lobo was the name of the band that sang A Dog Named Boo, so long ago that I can’t even admit I know the tune. I heard it during my formative years, the ones still a-forming.

Like Arlo Guthrie on his motorcycle I don’t want to die. Despite drinking kettle de-scaler yesterday morning, calling NHS 111 and having a not-great day thinking I might actually die of this, which wasn’t helped by eating a whole packet of spicy beetroot. I love that stuff, except they really ought to put a reminder on the packet of what happens when you look in the toilet bowl, to tell you that you almost certainly will live more than another three days and if you don’t, it won’t be anything to do with beetroots, unless a beetroot lorry runs you over. The gist being that I’d quite like to stay alive for the foreseeable future.

So obviously, I bought myself a motorcycle for Christmas. Unlike the song, although I’ve got my motor running, first time every time, but hey, it’s a BMW. On which I have no intention of hitting the highway like a battering ram, nor like anything else. What did you expect? I’ve absolutely no wish to hit the highway because I know from past experience it bloody hurts. Thankfully, my off-bike excursions were few and decidedly minor, but I remember spending an afternoon in Gene Fleck’s Meadow Inn bar in Wisconsin with the road closed while an emergency crew searched against the clock to find someone’s foot. I’d seen him and his girl earlier in the day on a Harley, riding like an accident looking for somewhere to happen, which it duly did.

I wasn’t prepared for the change. And no, that wasn’t why I got a motorcycle again. I did it because life is short. I did it because I wanted to smell the grass and the trees and the fields I passed through. I did it because I wanted to do it again before I die.

Where I began the process I laughingly call growing-up, there wasn’t any public transport to speak of. There were infrequent busses, taxis weren’t a thing for a 16 or 17-year-old in a Wiltshire town and even if being chauffeured to places by my Mummy was an option the way it seems to be for kids today, I’d have died of self-loathing to ask. Probably. After I had the lift, obviously. All of which meant that at 16 I did what was the fairly normal thing and bought a Yamaha FS1-E. It wasn’t just me. Look at the sales figures. Back then, you had a moped only as long as it took to get a motorcycle, which was your 17th birthday. Thanks to some bureaucratic insanity, or more likely in England, nobody could be bothered to check the sense of the rules, or read them properly, a 17-year-old could perfectly legally if predictably briefly stick a sidecar on a Kawasaki Z1, stick L-plates on it and set off for the obituary column of their local paper, when there were such things.

Not me, baby. I bought a Honda CB 175. I had an Army surplus shiny PVC button-up coat. It felt like, it looked like, it probably was something a dustman on a motorcycle would look like, as a friend of mine thoughtfully pointed out in case it was something I’d overlooked. It had to go, even though it didn’t very fast. I put it in the Wiltshire Times. Nobody even rang the phone number. I put the price up 30% the next week and got about 20 calls. I sold it to the first one who came to see it, even though he asked for a discount. Which he didn’t get. I didn’t bother to tell him about the 30% discount he could have had the week before.

Then it was probably my favourite bike, the Triumph T25, the kind of thing that now sells for over £4,000 any day of the week and which then you felt lucky if you could raise £200 on it. It was fun, and I learned some good lessons on it. One of them being that if you ignore that little triangular sign warning you there’s a junction ahead then you’ll go about three-quarters of the way across it before the twin-shoe Triumph brake stops you. Nothing came. Nothing did on back lanes around Tellisford in those days.

The Triumph got swapped for a Norton 500 that ran for two weeks out of the two years I had it. It sent me spinning down the road like a dead fly in Cardiff one black ice night, after I’d left the electric fire warmth of some girl’s flat (nothing doing there; never was, with anybody), lost the bike out from under me at about 5 mph, came to a halt against a parked car and had some Welshman peer down at me to tell me “Duh, it’s icy mind.” I left Wales as soon as I could and bought another Triumph, a real 1970s post-Easy-Rider identity crisis machine. It was a 650cc Tiger engine, shoehorned into a chrome-plated Norton Slimline frame. Instead of the rocker clip-ons you’d expect, it had highish handlebars and cut-off exhausts. Just header pipes in fact, but with Volkswagen Beetle mufflers smacked into them in a Bath carpark, with Halford’s slash-cut trim bolted on the ends. I wasn’t a rocker, but I thought it rocked.

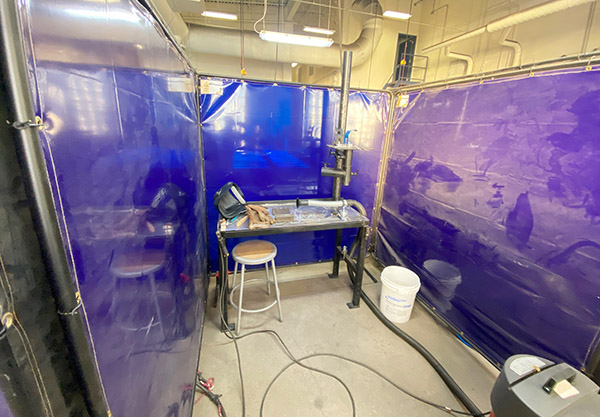

It took two weeks to get the petrol tank the way I wanted it, a deep, deep black you could lose your soul in, sprayed on then sanded, sprayed on then sanded, sprayed on then sanded about fifteen times in the kitchen of my definitively smelly Southampton student flat, the kind of place that gave Ian McEwan the idea for The Cement Garden, only a bit less appealing. On the first trip out on that gloriously glossy bike I rode up to Salisbury, escorted by a girlfriend whose parents purported to believe that she had her own spare room at my university halls of residence, the ones I’d left months before. We got to her parents’ newish house in the summer sunlight, said hello, put the bike in the driveway. Then decided we’d go to a local pub because a) Wiltshire, b) nothing much else to do until her parents went out, or c) that’s what people did.

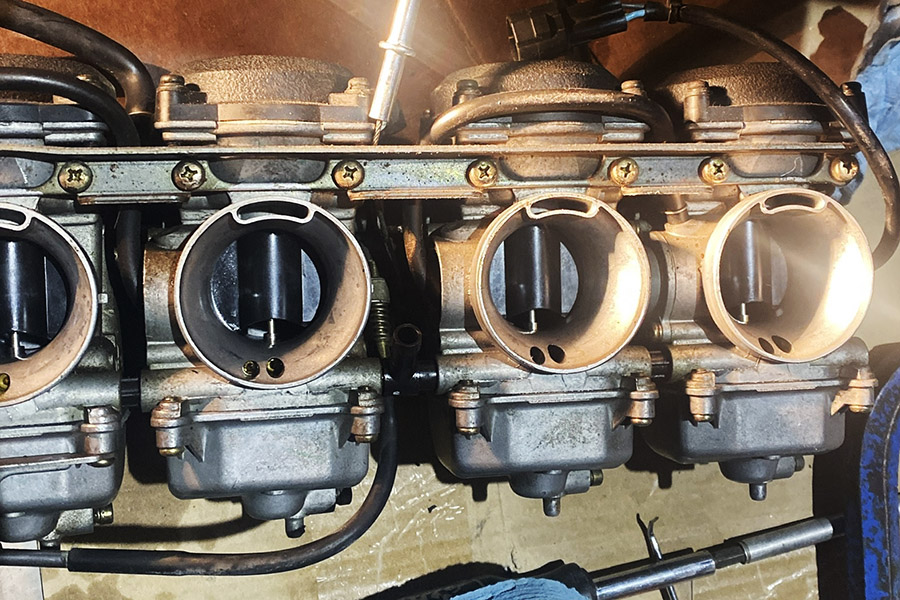

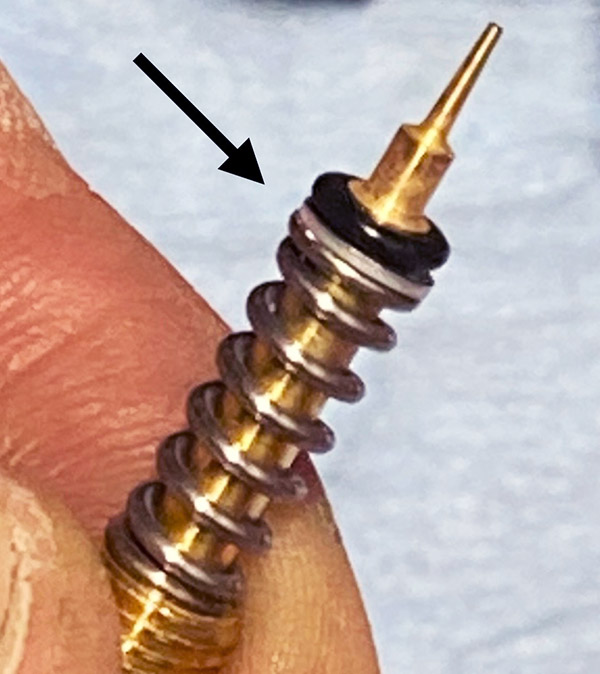

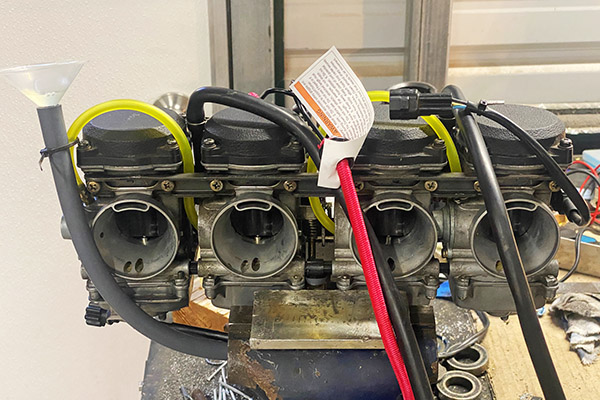

I started the bike, but it didn’t fire first time, so I tickled the Amal carburetor and tried again. There was no air filter on the carb – there often wasn’t in those days – so when it backfired the spurt of flame came straight out into the open air and set light to the petrol that had trickled down the outside of the carb float bowl. I appreciate that these are words that younger readers won’t even recognise, but we had to. I had my leather jacket on, a full-face Cromwell ACU gold-rated helmet, and long leather gloves, so I just reached down nonchalantly to switch the fuel tap to Off. No petrol, no fry, as Bob Marley didn’t sing. Except I didn’t turn the petrol off. I managed to pull the rubber petrol feed line off instead. The flames came up to chest level.

My first thought was to run for it, but my second was that I’d just put three gallons in the tank and I seriously doubted I could run faster than that. All I could think of to do was reach into the flames and turn the petrol tap off, so that’s what I did. I couldn’t see past my elbow in the flames, but it worked or I wouldn’t be telling this story. The insulation on the electrics had burned off so the horn was fused on until I got out my trusty Buck knife (something else we took entirely as normal in the West Country) and cut what was left of the wires. My girlfriend’s mother saw the whole thing from the kitchen. She waited until the flames had gone out before she came out to tell me I’d dropped oil on her driveway.

There was a break after that, for university and unhappily London then Aylesbury and Bath until luck and an unusual skillset saw me in Chicago, on a 650 Yamaha that might or might not have been technically stolen, blasting around Lakeshore Drive and the blue lights area, under half the city, overlooking some huge American river, me and an Italian buddy from summer camp on his bike, living if not the dream then certainly some kind of alternative reality. To this day I don’t know why I did that. No insurance, no clear provenance to the bike, certainly no observance of the speed limits, and only my trusty grey cardboard AA international driving licence that didn’t mention motorcycles. But nothing happened. Back then that was all that mattered.

A gap of some years and then a BMW R1000, a bike that vibrated so much that a trip from London to Wiltshire left me literally unable to make a sentence for about fifteen minutes. It felt good though, that lumpy, dumpy, so-solid bike. I traded that one for a Harley-Davidson Sportster which is what I thought was the ultimate motorcycle ought to be before I found out that I needed to spend £200 a month pretty much every month to get it the way it ought to have left the factory before their accountants had a say in the recommended retail price. It got stolen, we recovered it and instead of putting it back in showroom metal flake purple turned it jet black, bored it out to 1200, and put Brembo four-pot brakes and a fuel-injector on it before it transmogrified into a laptop and a laser printer, when laser printers were a long way from the couple of hundred a good one is now.

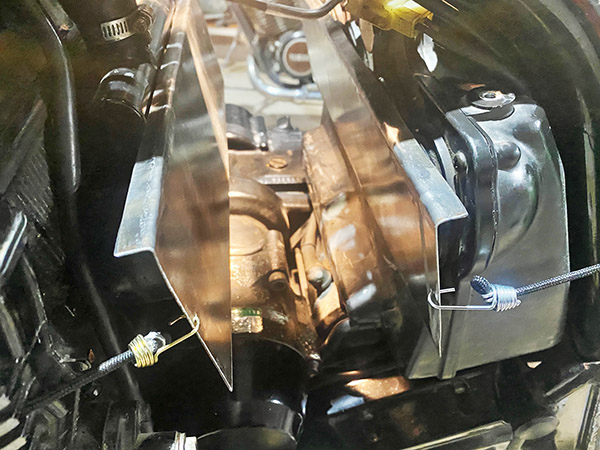

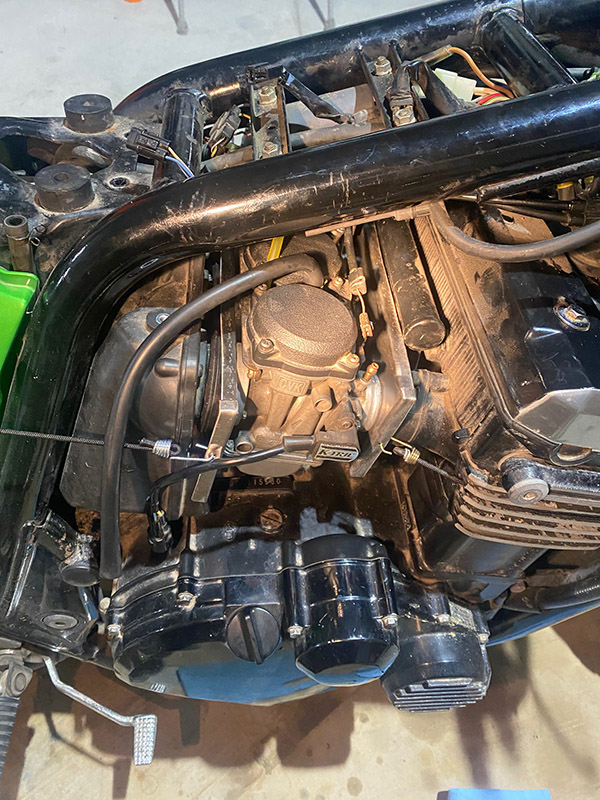

And somehow that was 30 years ago. This time the iron horse is a BMW F650, almost as old as when I stopped riding for a while, but with a documented 13,000 miles on it. My idea of common sense says changing the oil and the filter and swapping out the original brake lines and replacing them with stainless steel would first of all look cool but possibly more importantly, be quite a sensible way of not relying on thirty year old rubber. I mean, would you? On any Saturday night?

In the intervening coughty years I’ve either sold or given away my original Schott jacket, the gloves, the Rukka, the Ashman Metropolitan Police long boots and the Belstaff scrambler boots. The Cromwell helmet and the Bell 500 open-face are long gone. I need everything, from the toes upwards and I find that most of the names I grew up with such as Ashman or Cromwell just don’t exist any more. I bought another Bell, but a full-face ACU gold Sharp 5-rated lid this time. I got some gloves, some chain lube and a tube of Solvol Autosol to keep the chrome shiny. I found some leather jeans and my old not-Schott jacket that I bought in Spain and after only three applications of neatsfoot oil and old-fashioned dubbin and hanging it over a radiator it’s now soft enough to be wearable and looks, I think, pretty darned good, even if it doesn’t have a single CE rating to its name. I’ve skipped the red Hermetite that used to decorate every pseudo-serious biker’s jeans.

Of the kids I knew that got in Bad Trouble on a bike, one was drunk and showing off. He died. My cousin lost his job and an inch off one leg when he was swiped by a car that ignored him on a roundabout. One in Wiltshire rode his bike under a combine harvester. He died too. It wasn’t really funny and I try not to think of him looking like SpongeBob SquarePants, with his arms and legs sticking out of the straw. He’d had a 20-year break from bikes and had just picked up an early retirement pension payoff. He didn’t read the T&Cs that said you still can’t ride like an arse. The American guy I didn’t ride around Chicago with lost his foot and they didn’t find it in time to put it back on. For all I know it’s still in a field in Wisconsin.

CE-rated armour wouldn’t have helped a single one of them. I’m certainly not saying safety gear isn’t worth the effort, or I wouldn’t have specced out my new helmet so carefully. But motorcycles aren’t the safest thing. You have to watch your sides, your front and what’s underneath you, as well as your back.

Like what you read hear? Check out (and subscribe to) Carl Bennett’s blog at Writer-Insighter.com!

Never miss an ExNotes blog:

Don’t forget: Visit our advertisers!

Arriving at my hotel around 11:00 a.m. I knew it was way too early to check in and for some reason I had a lot of energy. I found a local island on a map and saw ferries frequented it. What a great way to spend my first day. The island was like a little Martha’s Vineyard with shops, restaurants and bars. It also had a short hike up to the highest point on the island, Mt. Victoria. The hike got my legs moving again after my long flight. Once I began feeling tired I ferried back to Auckland. Upon disembarking the ferry I was starting to feel a bit tired so I thought taking one of those Lime Scooters would be a great idea. Well, I now know how I am going to die. It will be on a Lime Scooter. Not only was I starting to fade fast but the traffic drives on opposite the side of the road. Fortunately for me people are super nice here and I didn’t hear one F-Bomb as I clumsily navigated my way back to the hotel on the scooter. I was asleep within an hour. What a cool first day in New Zealand.

Arriving at my hotel around 11:00 a.m. I knew it was way too early to check in and for some reason I had a lot of energy. I found a local island on a map and saw ferries frequented it. What a great way to spend my first day. The island was like a little Martha’s Vineyard with shops, restaurants and bars. It also had a short hike up to the highest point on the island, Mt. Victoria. The hike got my legs moving again after my long flight. Once I began feeling tired I ferried back to Auckland. Upon disembarking the ferry I was starting to feel a bit tired so I thought taking one of those Lime Scooters would be a great idea. Well, I now know how I am going to die. It will be on a Lime Scooter. Not only was I starting to fade fast but the traffic drives on opposite the side of the road. Fortunately for me people are super nice here and I didn’t hear one F-Bomb as I clumsily navigated my way back to the hotel on the scooter. I was asleep within an hour. What a cool first day in New Zealand.