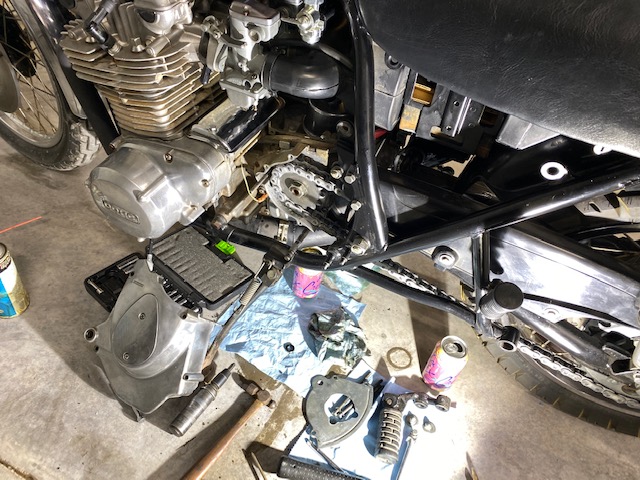

I don’t want to give you the wrong impression. It sounds like I’m having lots of trouble getting Zed back on the road but it’s really more a function of my resurrection approach. I tried to spend the minimum amount required to get the 1975 Kawasaki Z1 operational because I didn’t know if the engine was shot or if the transmission slipped out of gear under load. Having done that, and proven to myself that this 900cc mill is a sweet one I can invest more money into some age-related issues.

On my first 30-mile road test I had a two copious oil leaks and I resolved those in a previous story. Zed was ready for a more ambitious undertaking. I laid out an 80-mile round trip to the Three Rivers, Santa Nino De Atocha church. The Santa Nino is off the beaten path but is still in use. Next door to the church is an interesting graveyard that I planned to commune with the spirits in while I sipped my thermos of Batdorf & Bronson® coffee. Hanging out with dead people is a great way to avoid catching the corona virus.

Zed ran strong and we made it out to church in fine tune. I parked the bike, pulled out my thermos and prepared for the séance. Then I noticed the gas leak. A panic set in: how long has it been leaking? Will I have enough fuel to get home? Won’t I look pretty stupid after hating on tank sealer for so long?

I took a big slug of coffee in case the situation spun out of control and I had no time later. Popping the seat I could see a thin stream of fuel shooting from the left rear seam directly into the air box inlet screen. It was strong, pretty thin and 3-inches long…Ahem…

I never go anywhere on a motorcycle without tools so I had vise grips in my bag (that was strapped to the much-hated luggage rack) and managed to crimp the seam slowing the pinhole leak. Fuel was still seeping but at least it wasn’t spraying out. I took one more slug of coffee for the road and reloaded the bike. Since the leak was using fuel faster than I was burning it I cruised back at a brisk 80 miles per hour. I had less than a gallon left when I got home, a 20-mpg average.

This next part will require so many disclaimers that the blog would crash under the weight of them. Listen, if you don’t know how or are even slightly worried about welding a fuel tank then don’t do it. If you choose to weld on a fuel tank don’t come crying to me pointing at bits of sheet metal stuck in your eye.

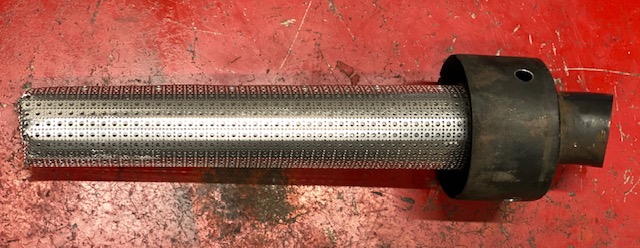

After draining the tank I blew it out with a grass blower to dry out any residue. Next I shot a heat gun into the filler neck to warm up the tank, hoping to evaporate any remaining fuel. Then I blew it out again and gave it the heat gun treatment again. This all took about ½ hour.

My finely calibrated nose told me that the fuel/air ratio inside the tank had dropped to safe levels. You can’t teach this skill; it’s like wine tasting. You have to blow up a few gas tanks to get the knack. I took the tank outside where there was plenty of room to explode and stuck a lighted propane torch nozzle inside the tank. The tank did not kill me. I was ready to weld.

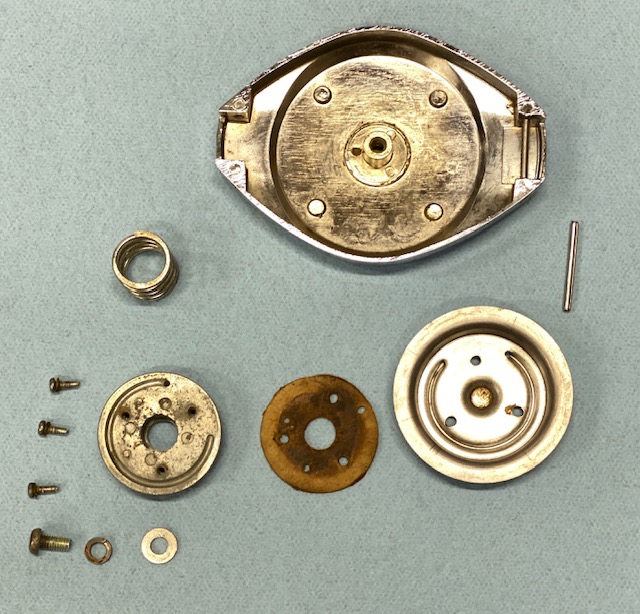

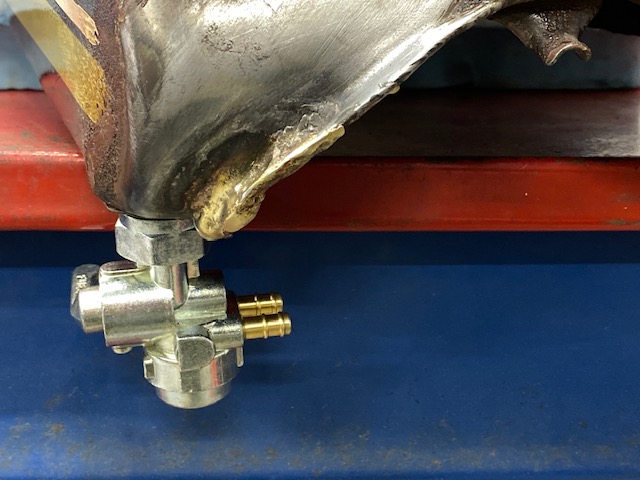

I knew where the pinhole leak was but I brazed a wide area on either side in case other leaks were concealed by the main leak. I use brazing rod instead of welding the tank because the metal was so thin I would burn through trying to cover the amount of tank I wanted to cover. Once I thought that I had piled on enough material I reinstalled the fuel tap, filled the tank and waited to see if it would leak.

The tank stayed nice and dry. It was time for another test run, this one 140 miles in duration. Zed passed with flying colors. This bike runs smooth at 4800 RPM and 70-ish miles per hour. Hills and headwinds don’t bother the thing and I had plenty of both on the third test run. I averaged 40 miles per gallon running 70 most of the trip.

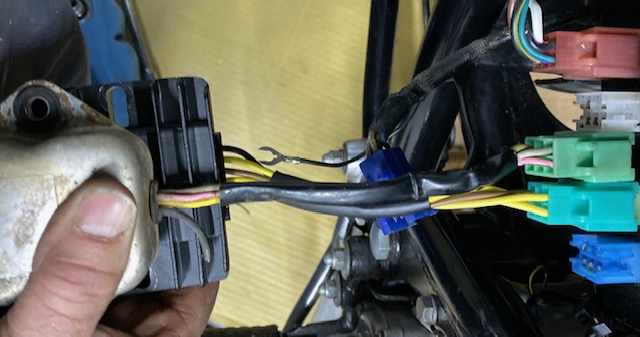

The half-circle cam-end rubbers leaked oil but I knew they were leaking and I have new ones on order. The alternator wire harness leaks a few drops where it exits the stator housing. That will require a new grommet. The speedometer is jumpy above 60 miles per hour. I’ll try a new cable but I suspect the grease has dried out inside the gauge. Low beam blew out in the headlight. That may be due to the 14.8-volt charge rate or the old bulb that came in the headlight was ready to go. I’ll install another bulb and if it blows I’ll knock down the voltage to the headlight. Otherwise nothing really bad happened.

Zed has proven to be an excellent runner so there are a few more things I want to do to the carburetors. New needles and seats, enrichener plunger seals, bowl gaskets and free up the stuck bowl drain screws. Kind of tighten up the carbs as it were.

Now we come to the elephant in the room: the fuel tank. Zed’s tank was very rusty before I cleaned it out. That rust has eaten deep into the seams of the gas tank. I don’t believe my patch job is a permanent fix. Maybe not today, maybe not tomorrow, but someday another thin spot on the seam will give way and start spewing gasoline. Zed’s patina is cool and all but I plan on taking some long, lonely motorcycle rides and that gas tank worries me. I know I could pour that devil’s brew tank liner crap inside and buy a few years of service. A new Z1 aftermarket tank in grey primer is $300. Or I could use Trump’s stimulus check on a whole new set of Z1 Enterprise’s red bodywork (tank, fender, side covers) beautifully painted in the original Kawasaki style for $1300.

I’m cheap but that Z1E bodywork would make old Zed look like a new motorcycle. I have no bias against a nice looking motorcycle. I don’t need to ride a ratty bike, you know? Any suggestions?

Check out the compleat Z1 resurrection here!