By Joe Gresh

Labor rates at motorcycle shops are well over $100 an hour and that fact got me thinking about the value of old motorcycles. Take my 1999 ZRX1100: The basic bike is sound but there are many minor issues that add up to a lot more money than the motorcycle is worth. If you took the bike to a shop, that is.

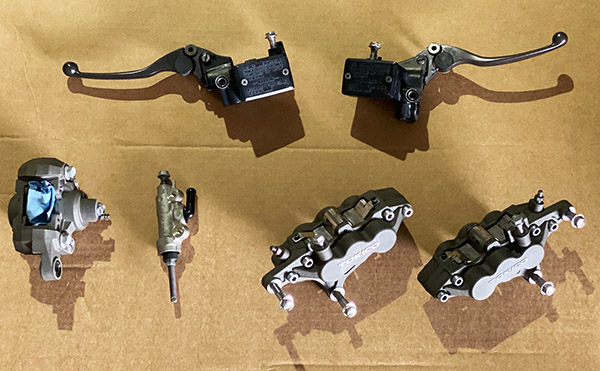

Fixing a bike yourself means you can take more risks. You can reuse iffy parts that a dealer mechanic cannot. The brake system on the Rex was in sad shape. All the calipers were stuck and the master cylinders were stuck, too. If I worked for a shop as a motorcycle mechanic I’d tell the customer they need all new parts. I couldn’t take the risk of my rebuilt caliper failing or coming back for a leak.

The bores in a brake caliper are not super critical as the sealing is done mostly on the piston walls. Unfortunately, my caliper pistons were not in great shape. I polished them as much as I could and cleaned up the bores. New o-rings and dust seals will hopefully keep them from leaking.

The master cylinder bore is much more critical because it forms the sealing surface for the piston and seals. Luckily the bores on the clutch and both brake caliper master cylinders were in good shape.

The rubber bits for the front and rear master cylinders looked ok-ish to me so I reused those parts. I’m to the point that I prefer old OEM bits to new aftermarket bits if I can get away with them.

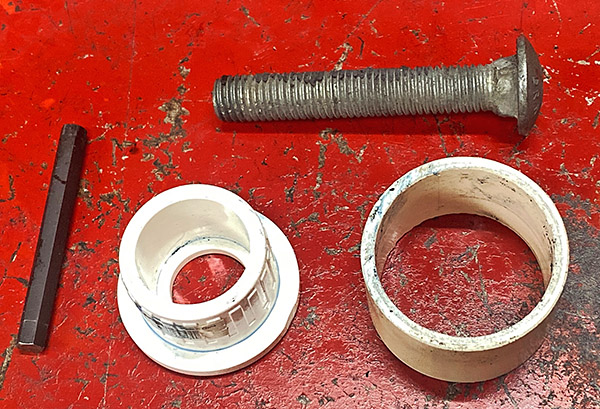

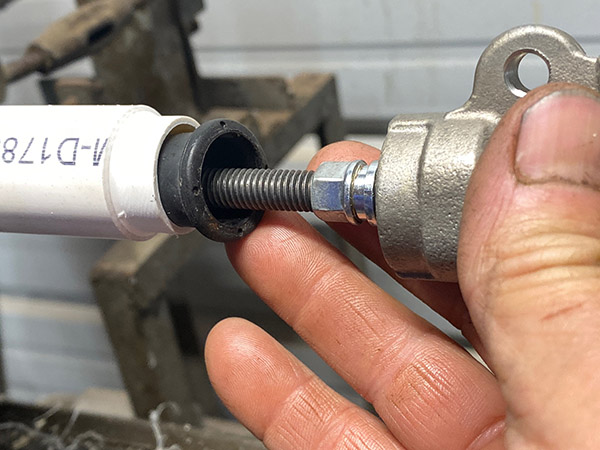

The levers have a pressed in dust seal and I didn’t have a tube the correct size for the job so I turned out a short piece of PVC tubing to push the dust boot into place.

I ordered a new clutch master seal kit as I tore the original dust boot dismantling the thing. I also bought a clutch slave kit but the bore was so bad by the time I had it remotely smooth the piston was loose in the bore. I have ordered a new clutch slave cylinder.

All in, there were 18 hydraulic pistons in the ZRX that needed service. A shop mechanic would never re-use the stuff I did. It may come back to haunt me later.

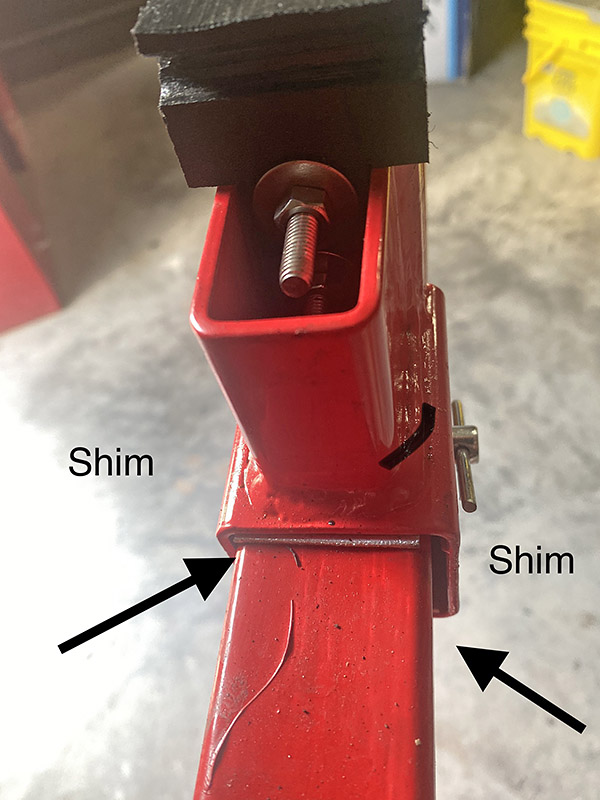

I bought two new, made in Malaysia Continental tires for the Rex as the ones on the bike were made in 2009. The old tire sidewalls had small weather checking. I would have run the old tires if I was just bopping around town but I have a few long trips planned so at $200 for the pair I figured I’d better bite. The Harbor Freight tire changer made the job tolerably easy. Still not as easy as having a shop do it.

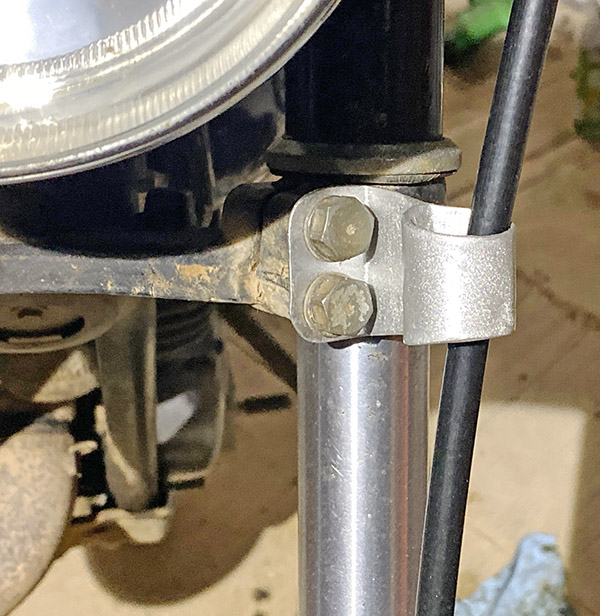

The fork seals were leaking so I popped in a new set of fork seals and replaced the fork oil and while I had the front end apart I dropped the lower triple clamp and pumped in some much needed grease to the steering head bearings.

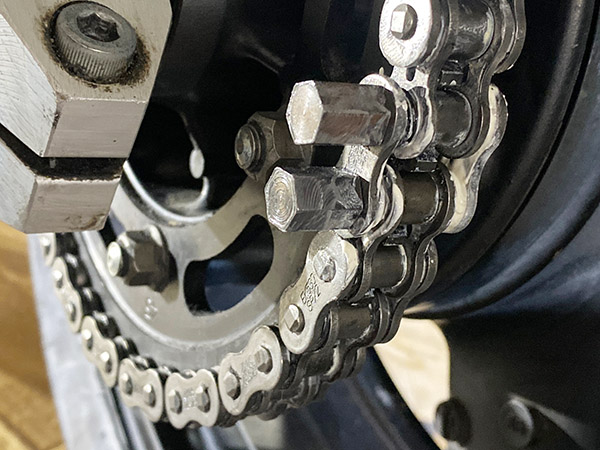

I also bought a new front sprocket and new X-ring chain for the Rex. The chain had a new style master link that worked by pressing the side plate on using small nuts then breaking off the studs that stick out. If it works it will be a good idea, if not I’ll probably break my engine cases when the chain lets go.

If I had taken the ZRX1100 to a shop by this point I would have already exceeded the value of the motorcycle. A shop would need to put in all new brake components to cover their butt. I’m willing to risk my life on shoddy equipment to save money and I’m nowhere near done with the bike or spending money, as you’ll see in future blogs.

Keep the hits coming: Please click on the popup ads!

More Resurrections are here!