By Joe Gresh

Parts for Yamaha’s RD350 are fairly easy to get but that didn’t stop me from hoarding a new top end set from eBay for the low, low price of $190. For that paltry sum you get two brand new cylinders, two brand new pistons, two brand new ring sets and two brand new wristpins with keepers. My buddy Bodden tried to warn me off the kit saying that the Teutonic name was a ruse and that Yamaha parts are far superior and I believe him. Still, $190 for an entire new top end? I had to bite.

First, there’s nothing wrong with my RD350; it runs great. I bought the Kveldwulf kit more as a spare and hedge against future scarcity. The kit is made in China; you know how international relations are going. We could be cut off at any moment. Unlike many people I don’t have a kneejerk reaction to Chinese products. I give them a chance to see if they are any good. In retrospect I probably should have bought an American made replacement RD350 top end kit (and I will if a company in the USA ever decides to manufacture one).

This particular top end kit has its problems. The biggest problem is that the right side piston won’t actually fit through the right side bore. The piston slides in about halfway and stops. Of course I could force it but the bike would only run a few minutes before it seized up. The left side is better but still feels a bit tight to me. What this means is I’ll have to have the cylinders bored to suit the piston size, a process that will probably cost more than the whole Kveldwulf kit.

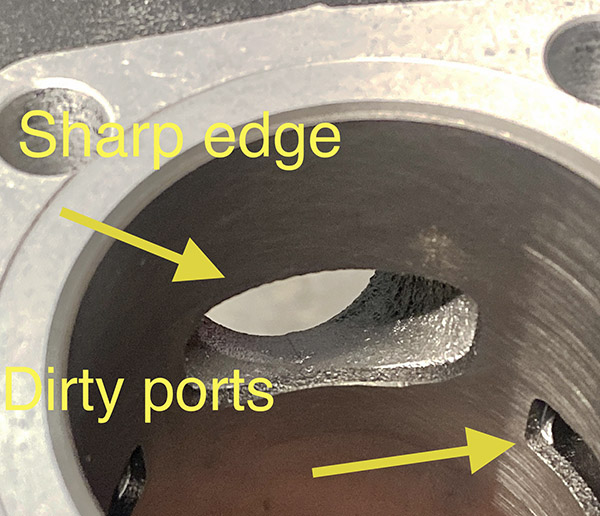

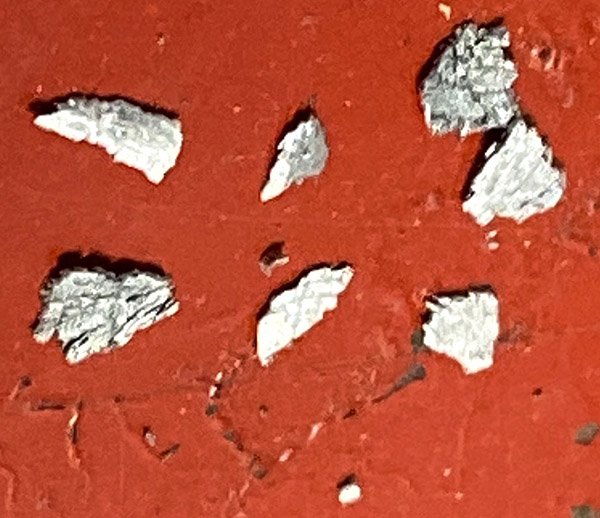

The ports on the kit cylinders are sharp edged and dirty looking. I think I’ll need to chamfer the port edges before using the cylinders or the thing will probably snag a ring. It wouldn’t hurt to run a burr through the ports to knock down some of the roughness either. When I unpacked the box there were quite a few loose bits of aluminum sprinkled throughout. A thorough cleaning is in order before bolting these parts onto my RD350. So the kit is not at a plug and play type deal.

The Kveldwulf pistons come with a Teflon-looking coating. I usually don’t like any of these new-fangled coatings and prefer plain old aluminum. I don’t have my RD350 apart so I can’t check the cut-away skirt and windows to see if the stock piston is the same. I’d also like to compare the ports to a stock cylinder to see how close the new stuff comes to original.

My best translation of Kveldwulf is “night wolf” and the prospects are indeed dim for this dog of an RD350 top end kit. I haven’t decided if I’m going to send it back and put up with that hassle or keep the kit and spend the time and money to remedy all its faults. I suppose if you had a RD350 that was missing its top end or it was severely corroded with broken fins the Kveldwulf kit would move you closer to the goal of a running motorcycle. You’ll have some sweat equity in the thing for sure.

If you have a stock RD350 and want to experiment with altering the ports but don’t want to mess up the original stuff this kit would be a cheap way to learn about two-stroke power bands without risking a ton of money. Then again, maybe I just got a dud. I’ll try to contact the eBay seller; they might take this top end set back and send me another one that is machined correctly. As delivered, I would only use the Kveldwulf kit as a last resort if my top end were totally wiped out, which is a hard thing to do with all the oversize pistons available. I’ll keep you updated whatever happens.

More ExNotes product reviews!

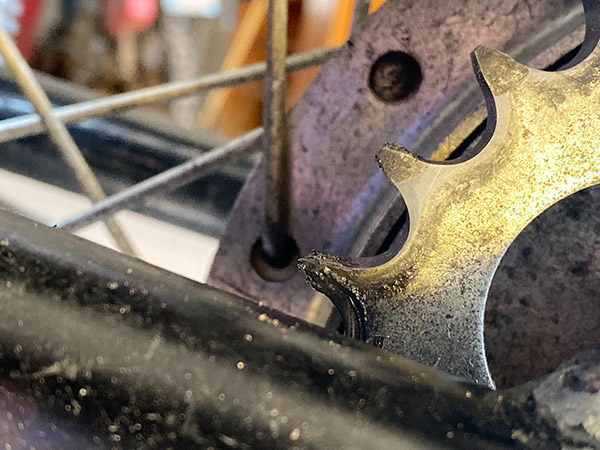

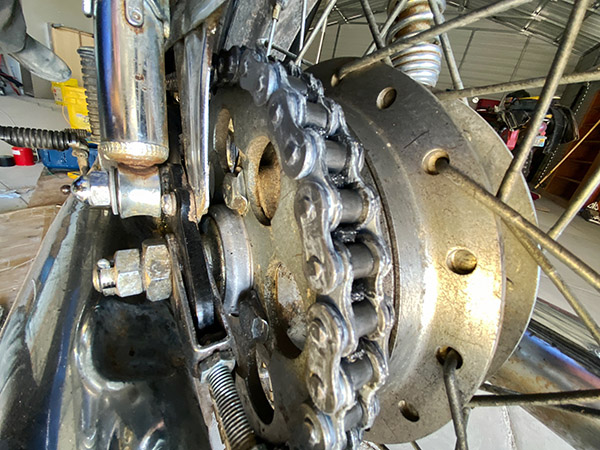

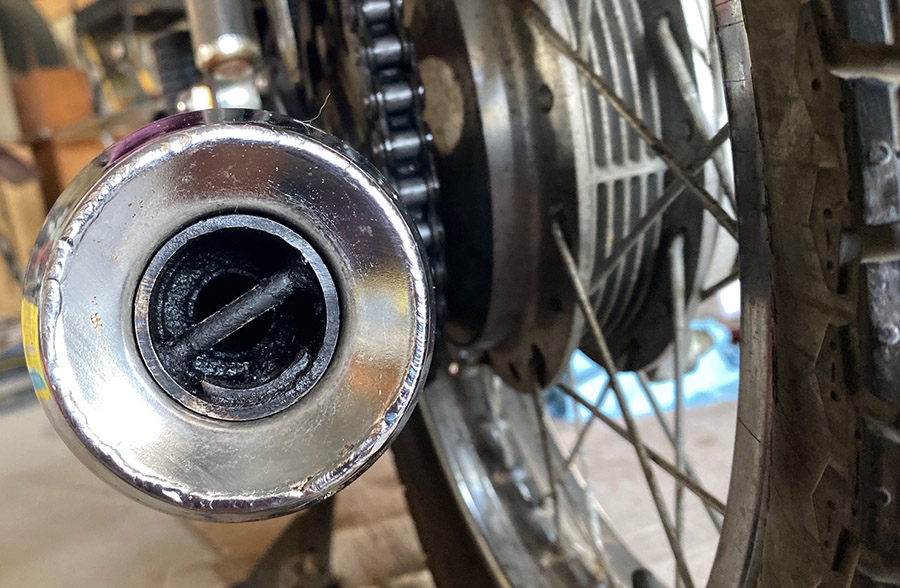

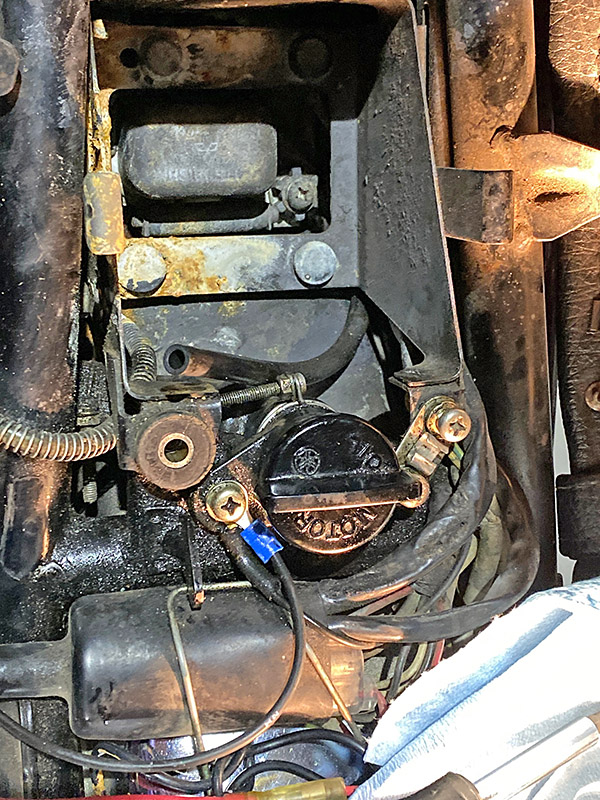

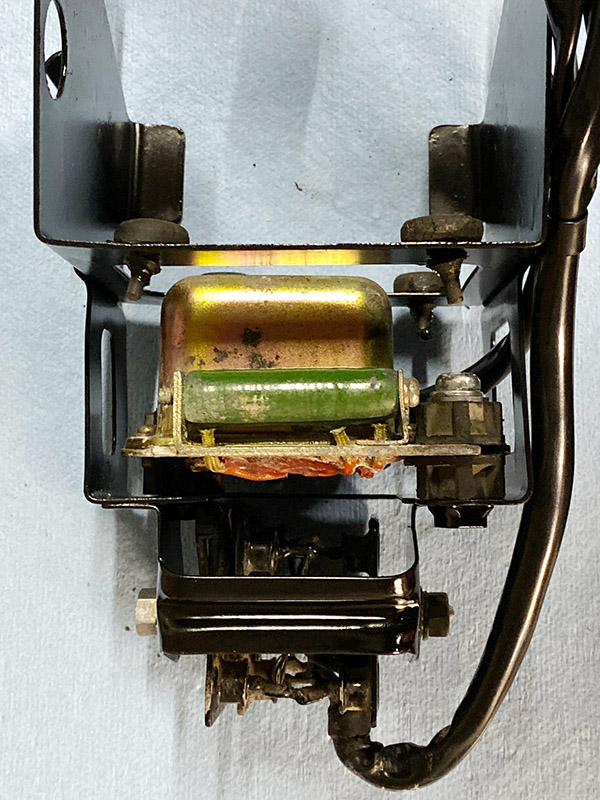

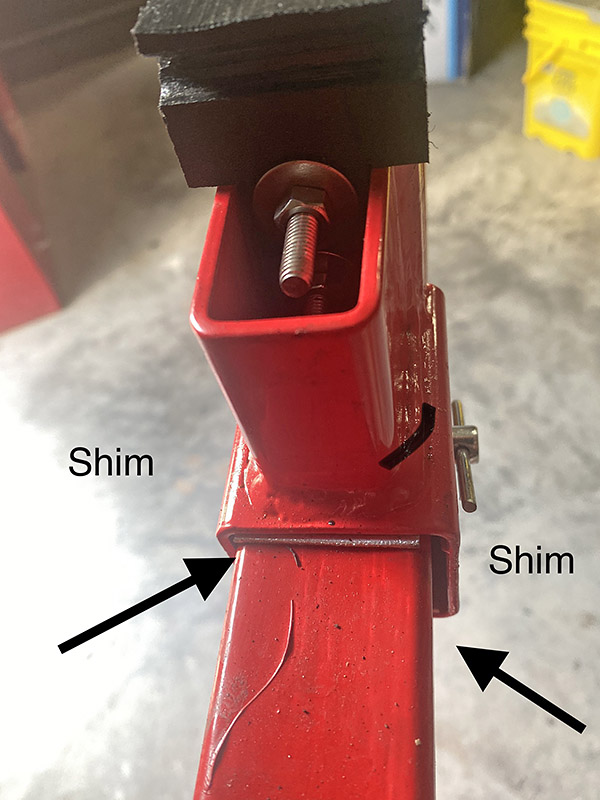

While I had the clutch helix cover apart I decided to install a new chain. I’m not one of those, replace-it-all-or-you’ll-die, type of guys. If the sprockets look unworn I’ll slap a new chain on the old sprockets. I realize this is hearsay in the Big-Sprocket boardrooms but those guys are in the sprocket selling business. The RD sprockets look like new so don’t worry, it will be fine. One glitch was the old tire is a 3.75-18 IRC, the bike calls for a 3.50-18. The narrow swingarm of the RD can barely accommodate the extra ¼ inch. I had to adjust the chain a wee bit tighter than I like to keep the tire from rubbing the front of the gusset. That problem will be solved when I replace the tires.

While I had the clutch helix cover apart I decided to install a new chain. I’m not one of those, replace-it-all-or-you’ll-die, type of guys. If the sprockets look unworn I’ll slap a new chain on the old sprockets. I realize this is hearsay in the Big-Sprocket boardrooms but those guys are in the sprocket selling business. The RD sprockets look like new so don’t worry, it will be fine. One glitch was the old tire is a 3.75-18 IRC, the bike calls for a 3.50-18. The narrow swingarm of the RD can barely accommodate the extra ¼ inch. I had to adjust the chain a wee bit tighter than I like to keep the tire from rubbing the front of the gusset. That problem will be solved when I replace the tires.