A month or so ago I wrote a blog about Lee’s .357 Magnum Deluxe 4-die set. I liked those dies so much I picked up a Lee 4-die set in .44 Magnum. I am similarly pleased with this latest set of dies. There’s too much info to fit into one blog post, so I’m presenting it in three blogs:

-

-

- This first blog is about the four different dies, what each does, and the parts in each die. Lee’s engineering is superior, and this blog showcases it.

- A second blog will focus on installing each die in my loading press, and how to adjust the dies to make world class .44 Magnum ammunition. Watch for this blog within the week.

- A third (and concluding) blog reveals how ammunition loaded with the Lee dies performed. The ammo was stellar and I’m a believer. Lee’s Deluxe 4-die set is a magnificent product and it makes magnificent ammunition. But don’t take my word for it. You’ll see it in the groups I shot. The accuracy blog will post in about two weeks.

-

So, here we go. When I reload, I start with fired ammo brass cartridge cases, like you see below.

And when I finish, this is what I have…newly reloaded ammunition as good as or better than factory ammo, at a fraction of the cost of factory ammo. That “as good as or better than factory ammo” descriptor is misleading. My ammo is better.

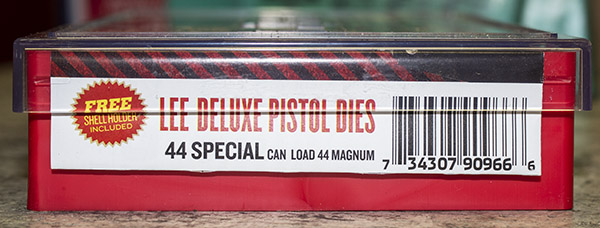

As most of you know, a gun chambered in .44 Magnum can also shoot .44 Special ammo (just like a .357 Magnum can shoot .38 Special). .44 Magnum dies can be used for reloading .44 Special ammo.

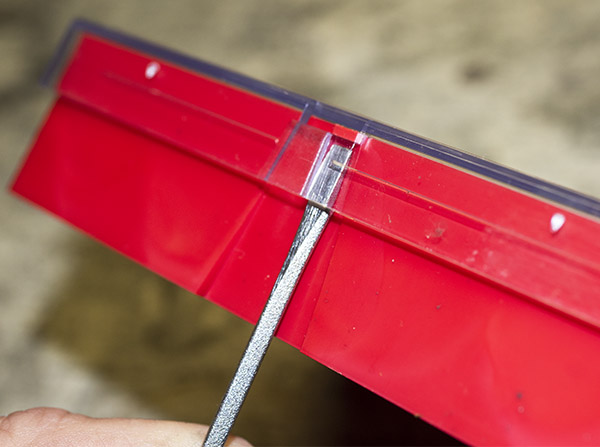

Lee dies come in a hard plastic case with a clear cover. The cover is removed by inserting a flat blade screwdriver on either side.

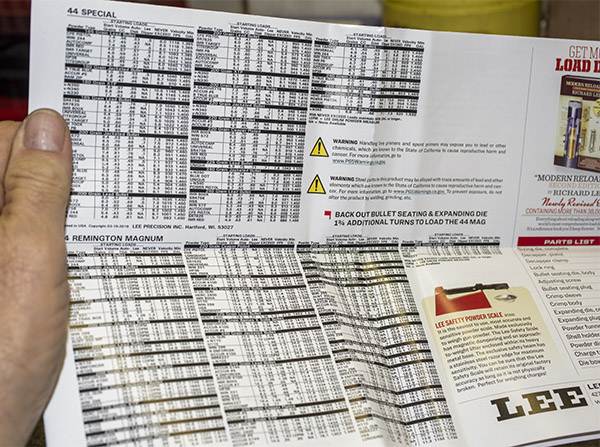

The Lee label unfolds to reveal directions on using the dies along with a bunch of other information, including several suggested loads. Over the last five decades, I’ve found a few .44 Magnum loads I like, and in particular, I have a favorite load I shoot in the Ruger Super Blackhawk. I will share more of that with you in the next blog in this series.

Lee’s Deluxe 4-die set consists of four dies, a shellholder, and a powder cup:

-

-

- A carbide sizing die.

- An expander die.

- A bullet seating die.

- A factory crimp die.

-

Here’s what the die set looks like after you remove the cover.

1. Sizing Die

The sizing die is a sizing and decapping die. When this die is installed in the reloading press and a fired brass case is inserted into it by raising the press ram, two things occur:

-

-

- The cartridge case is resized to its original diameter (it expanded when the cartridge was fired, so it needs to be resized to specification dimensions). The Lee die is a carbide die, which means is has a very hard carbide steel tube inside the die body. Because it is a carbide die, there’s no need to lubricate the cartridge cases for the resizing operation (like you have to do with plain steel dies). Carbide dies are much preferred for this reason.

- The used primer is pushed out of the cartridge case (this is the decapping operation).

-

Here’s the sizing die.

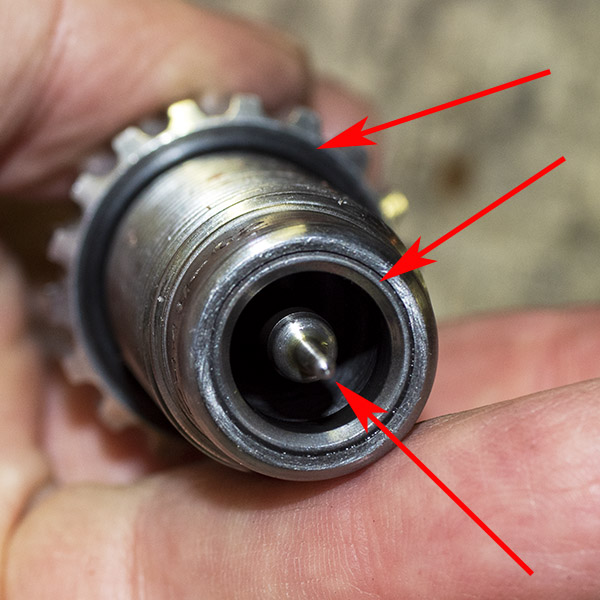

Here’s the sizing die from the bottom:

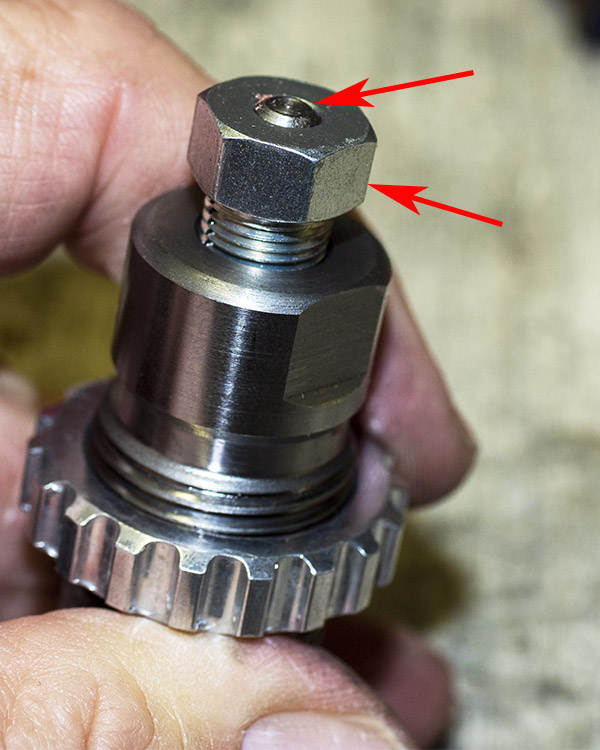

Viewed from above, the decapping pin is secured by a threaded collet that screws into the die body. It’s a good approach because if there is an obstruction (if the pin hits the case bottom rather than the primer through hole, or if the primer through hole is blocked), the decapping pin simply pushes up in the threaded collet nut. This prevents bending or breaking.

2. Expander Die

Once the cartridge case has been resized in the sizer die, it needs to be opened up slightly and the case mouth needs to be flared to allow a new bullet to be started in the case. This is accomplished with the expander die. Like each die in the Lee Deluxe 4-die set, this die includes a locking ring to lock the die in the reloading press. Some reloaders charge the case (add powder to the case) during the expander die operation. I don’t reload this way, and I don’t know any reloaders who do.

The Lee expander die consists of six components. These are:

-

-

- The die body.

- The locking ring and its oring.

- An oring between the die body and the through hole insert.

- An expander.

- The through hole insert.

-

These components are shown in the photo below.

The expander slides up in the die body when a cartridge case is inserted by the press ram. When it reaches the end of its travel, a ramp in the expander plug creates a flare on the case mouth. This is what will allow a new bullet to be inserted in the cartridge case. In the photo below, the expander plug is inverted from its installed orientation to allow a better view of this ramp

You might wonder why there is a powder through hole component at the top of the expander die, and why the ramped expander plug is allowed to move up and down as a cartridge case is inserted into the expander die. The through hole allows inserting powder into the case with the powder cup (which I don’t use). Other Lee reloading gear uses the expander plug up and down motion to activate automatic powder dispensing devices (this is the approach used on Lee’s progressive reloaders).

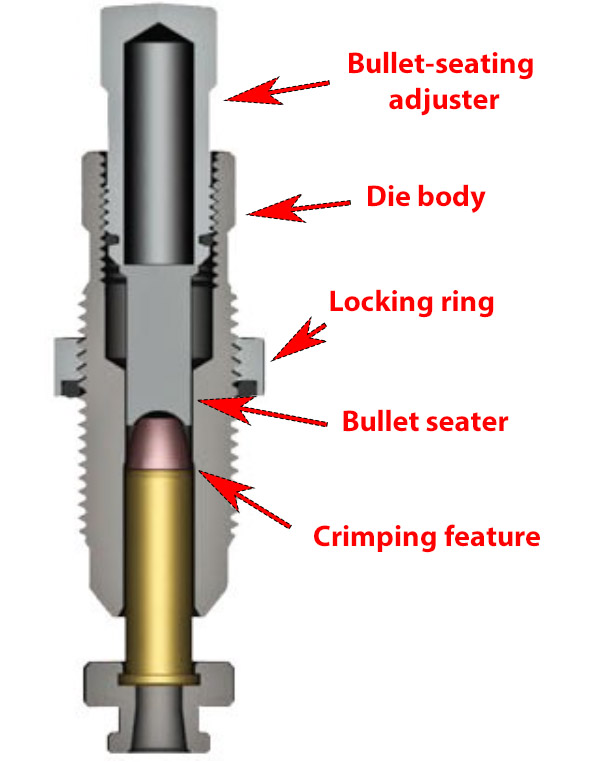

3. Bullet Seating Die

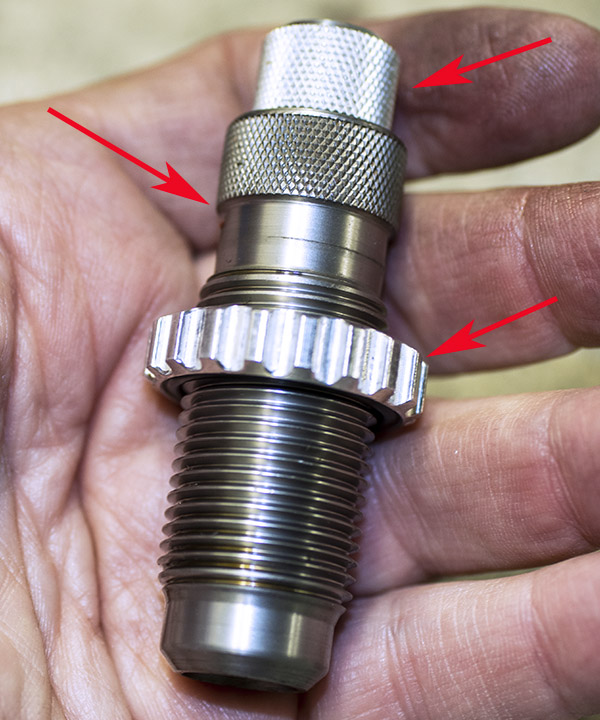

The bullet seating die is the third die in the Lee Deluxe 4-die set. This one is a bit more complicated than the first two because there are two adjustments, and this die can also be used as a crimping die. With the 4-die set, I am not going to use this die for crimping. I am only going to use it for seating the bullet to its required position in the cartridge case.

The bullet seating die is shown below.

Here’s Lee’s illustration of the bullet seating die.

From the outside, the bullet seating die and the factory crimp die appear to be almost identical. The easiest way to distinguish them is by the size of the knurled segment on top and by the length of the die body.

The bullet seating die parts include:

-

-

- The die body.

- The bullet-seating adjuster and its locking oring.

- The locking ring and its oring.

- The bullet seater.

-

These parts are shown below.

I mentioned above that I use this third die in the Lee Deluxe 4-die seat only to seat the bullet. It can also be used to crimp the cartridge case around the bullet, but I don’t crimp with this die. I use the Lee factory crimp die for crimping.

To adjust the die to do this, I run the bullet-seating adjuster well into the die body so that it pushes the bullet to its desired seating depth before the crimping feature reaches the cartridge case. I’ll describe this adjustment in more detail in tomorrow’s blog.

You might wonder: Why not do both (bullet seating and crimping) with this one die? Some folks do, and if you have the Lee 3-die set (not the Deluxe 4-die set), that is your only option for crimping. But this approach has the bullet still being inserted into the case as the crimping operation occurs, which invites potential bullet misalignment. To get around that, I use the fourth die in the Lee Deluxe 4-die set (the factory crimp die).

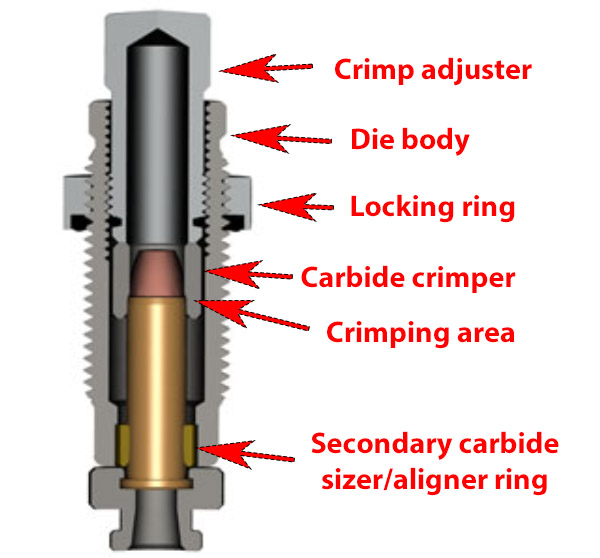

4. Factory Crimp Die

The factory crimp die does three things:

-

-

- It roll crimps the bullet in place.

- It maintains bullet alignment in the cartridge case.

- It removes any imperfections in the cartridge case to assure easy chambering.

-

Here’s the factory crimp die.

Here’s Lee’s illustration of the factory crimp die:

The factory crimp die has the following parts:

-

-

- The die body.

- The locking ring and its oring.

- A carbide crimper sleeve.

- The crimping adjuster and its locking oring.

-

These parts are shown below.

The carbide crimper shown above requires the cartridge case to enter the carbide crimper sleeve before the crimp is executed. This is an important feature, as it maintains bullet alignment with the case as the crimp is achieved and prevents case deformation that could interfere with chambering. Also, the bullet is not moving further into the case as the crimp is achieved, which is what would occur if I used the bullet seating die to crimp the case.

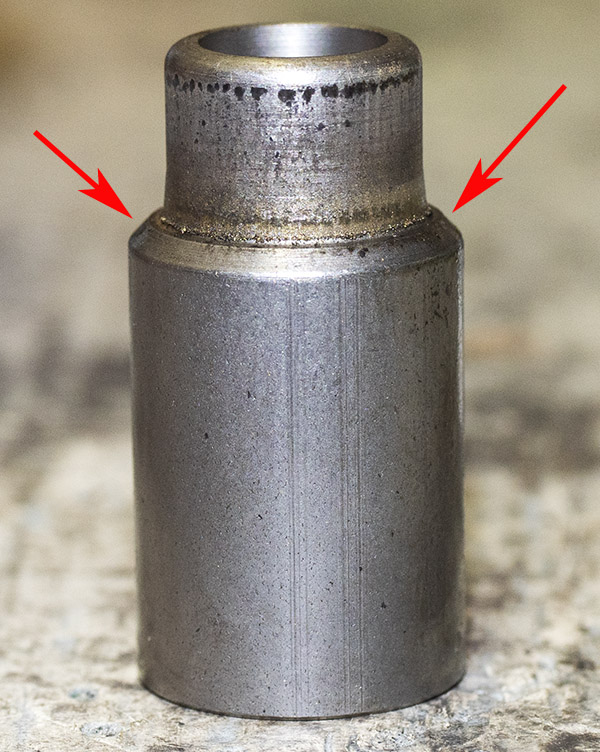

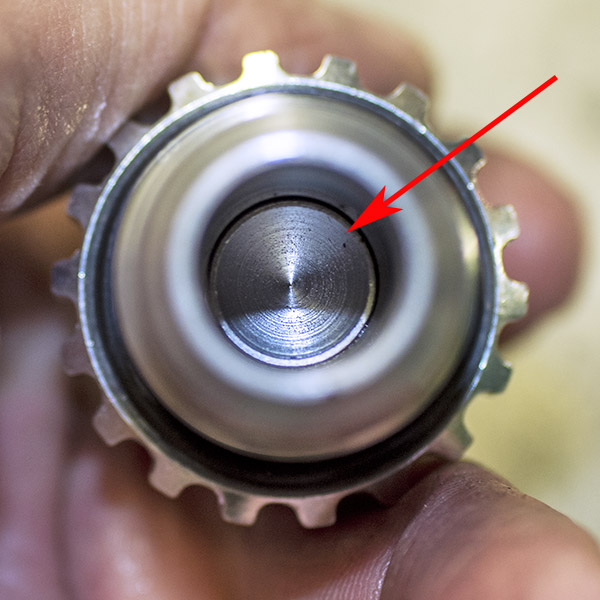

There’s another carbide ring at the base of the factory crimp die, shown by the photo below.

The factory crimp die lower carbide ring both prevents and removes any deformation in the cartridge case when the case is crimped and the cartridge is inserted and withdrawn from the die. This assures easy chambering and bullet-to-case alignment.

So there you have it. In our next blog, which will post in about a week, I’ll explain how I set up each of the dies in my press.

You might be wondering: Do these Lee dies really work? The short answer is an emphatic yes. I found when loading .357 Magnum ammo with the Lee Deluxe 4-die set that accuracy improved and bullet pull (bullets backing out under recoil) was eliminated. To jump ahead a bit, the .44 Magnum Deluxe 4-die set described in this blog resulted in stellar accuracy. I’ll cover that in a third blog, which will publish in about two weeks. Before I get there, though, here’s a teaser photo:

If you want to make sure you don’t miss any of the upcoming .44 Magnum Lee Deluxe 4-die set blogs, grab your free ExNotes subscription here:

Keep us going! Here’s why you should click on those popup ads!

For more info on Lee Precision reloading equipment, click on the image below:

Good writeup on the Lee Carbide 4-die pistol set. I have been using my Lee 44 die set for more than 18 years and I load a LOT of 44 mag ammo. I notice they have changed the lock nut design from the old style knurled aluminum rings to something that looks easier to get a grip on for cinching down tightly. I have been charging my cases through the powder-through case mouth expanding die because I use the Lee Auto Disk powder measure. I load up all four dies onto an aluminum cassette that slips right into my Lee Classic Turret press. Every caliber I load for has its own cassette. This Lee Turret press loads a pile of accurate and consistent ammo very, very quickly. The beauty of each set having its own designated cassette is that once set up you leave the dies on it forever and never have to adjust the dies again unless you decide to change bullet types and have to re-adjust the bullet seating die. The Lee Classic Turret press with their 4-die carbide die set is the best reloading setup in the business.

A few years ago I found a brand new RCBS die set on sale at a gun store that was going out of business for super cheap, so I bought it to load 44 special. I set this up on its own cassette so I did not have to adjust my Lee die set between 44 special and 44 mag loading sessions. There is no doubt that the Lee is a much nicer die set than the RCBS! And the lee set is much simpler to boot.

One last comment, it is not uncommon to read of handloaders who swear by Hornady and RCBS die sets. However, a huge percentage of these diehard fans seem to toss out their crimp dies and replace them with the Lee Factory Crimp die!

Looking forward to reading the rest of your blogs on the Lee carbide pistol die set.

Good points, Jose, and thanks for commenting.