By Joe Gresh

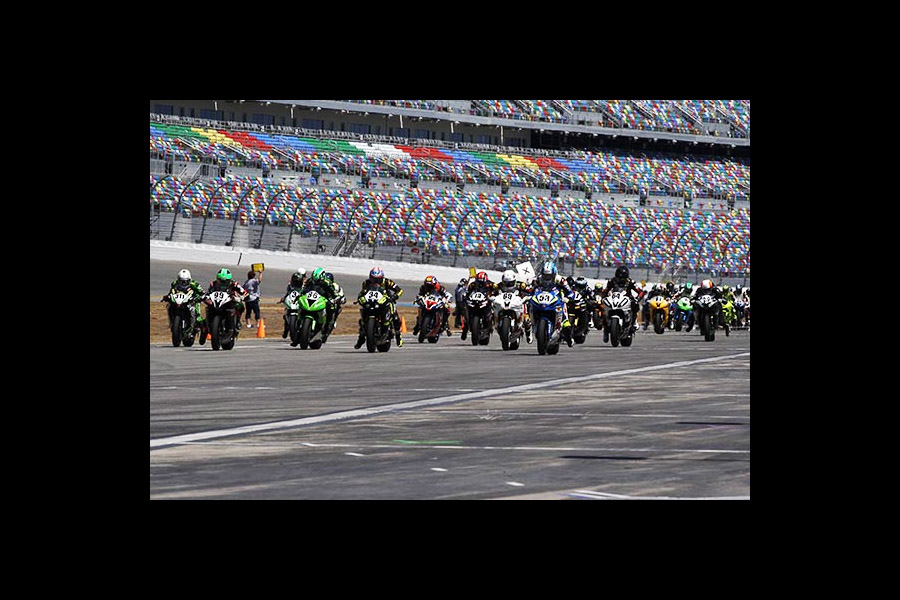

See that gap? That narrow space between the semi-truck hauling 20-foot long, 6-inch diameter solid aluminum rods and the BMW M6? I’m taking it, man, riding the horn button and twisting the throttle: zoom-zoom. See that intersection? The one with a whirlpool of scooters, three-wheeled single-cylinder diesel trucks and at least a hundred cars spinning left leaving eddys of pedestrians lapping at the edges? I’m a Hurricane Hunter riding straight into the maelstrom buffeted from side to side, tip-toeing around, swerving, cussing, sweating and focused, man, focused.

China’s city traffic requires all your intensity, taxes all your ability and is like nothing I have ever seen on the planet. There is no respite. There is no pause, You must lock on and track hundreds of individual trajectories from every point on the compass, constantly. Insane traffic scenarios unfold at a lightning pace, there’s no time to marvel at the stupidity. There’s only time to act.

The chaos is cultural: Chinese motorists drive like they’re riding a bicycle because they were only a few years ago. In less than one generation the Chinese have gone from pedals to 125cc Honda clones to driving millions of air-conditioned automobiles on surface streets designed for a sleepy agricultural nation. At any given moment dozens of traffic rules are being broken within 50 feet of your motorcycle. It’s a traffic cop’s dream.

Except that there aren’t any. For a Police State there are not many police in China. I’ve ridden entire days and not seen one Po-Po. My Chinese friends tell me the police show up for collisions but otherwise stay low-key. Because of this hands-off approach stop signs are ignored. Red lights mean slow down. You can make a left turn from the far right lane and no one bats an eye.

China uses the drive-on-the-right system but in reality left-side driving is popular with large trucks and speeding German sedans. Get out of the way or die, sucker. Painted lane-stripes are mere suggestions: Drive anywhere you like. Of course, sidewalks and breakdown lanes are fair game for cutting to the front of the cue.

China’s modernization process has happened so fast that the leap from two-wheeled utility vehicle to motorcycles as powersports fun never really occurred. In China there are millions of people riding motorcycles but relatively few motorcyclists.

If the cars don’t get you there are other strange rules that serve to dampen the popularity of Chinese motorcycling as a hobby. Motorcycles are banned on most major toll ways between cities. Law-abiding motorcyclists are shunted off to the old, meandering side roads. Which would be fun if they weren’t so infested with heavy, slow moving semi-trucks and near certain construction delays. In practice, since tollbooths have no ability to charge motorcyclists, Chinese riders blow through the far right lane, swerving to avoid the tollgate’s swinging arm. Ignore the bells, shouting and wild gestures of the toll-takers and roll the throttle on, brother.

Being banned from the highway is not a deal breaker, but being banned from entire cities is. In response to crimes committed by bad guys on motorcycles many cities remedied the problem by eliminating motorcycles altogether. Sales of new motorcycles in these forbidden cities is non-existent.

Rules designed to discourage motorcycling abound. Vehicles over 10 years old are not allowed to be registered, thus killing the used and vintage scene. Gasoline stations require motorcyclists to park far from the gas pumps and ferry fuel to their bikes in open-topped gas cans. Add to that the general opinion of the public that motorcycle riders are shifty losers too poor to afford a car.

So why do Chinese motorcyclists bother to ride at all? It’s not the thrill of speed; 250cc is considered a big bike in China and it’s really all you need to keep up with the slow moving traffic. I’ve spent a lot of time with Chinese riders and even with the language barrier I get that they ride for the same reasons we do: The road, the rain, the wind. After being cooped up in a high rise apartment (very few Chinese live in single-family homes) I imagine the wide-open spaces between crowded cities must seem like heaven. They did to me. Chinese motorcyclists and Low Riders ride a little slower, taking long breaks to smoke a cigarette, drink in the scenery or just nap. Every motorcyclist you meet is instantly your dear friend because we share this passion and despite all the minor regulatory hassles everybody knows love conquers all.

More epic motorcycle adventures? You bet!

Help us bring you more stories: Please click on the popup ads!

Want to read all about the China ride? Pick up a copy of Riding China!

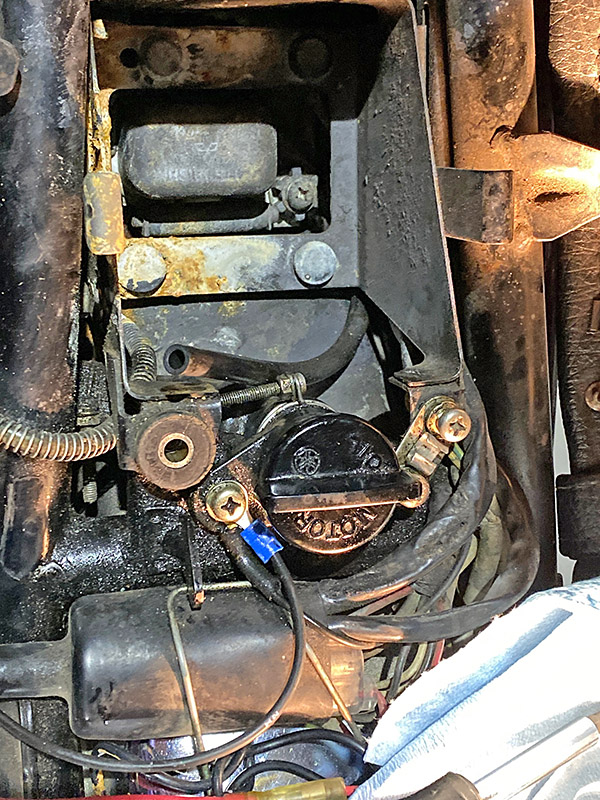

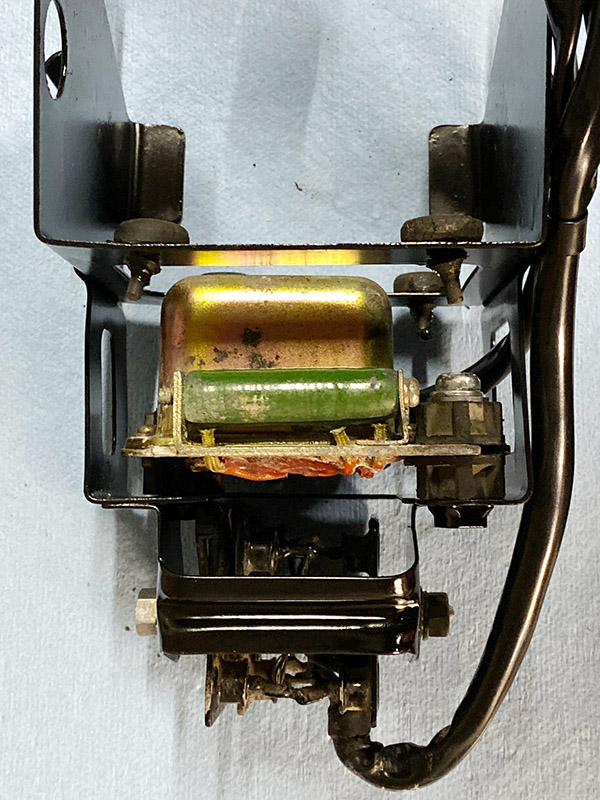

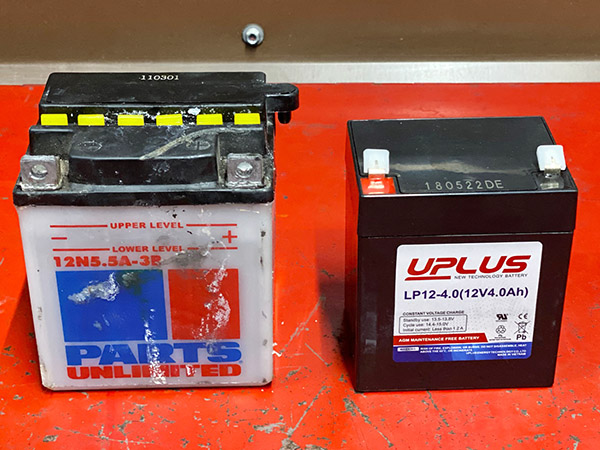

On of my largest assets is the 4-speed Suburban project. When I bought the ’90 ‘Burb it came with a malfunctioning automatic transmission. I hate automatics and malfunctioning ones even more so. The 700R4 works in Drive and Reverse but not in 1-2-3. The truck runs fine and it will tote a 3000-pound load without complaint but that boring automatic has got to go. It’s a rare Suburban that came with a 4-speed from the factory and even rarer to see a ½-ton version. I’ve only seen one 4-speed ‘Burb and it was ¾-on. This project keeps earning interest and I’ve been training a weather eye on Internet sale sites for a cheap, manual transmission, 4X4 GM truck to steal the guts from. I found a late model, 4X4-IFS 1/2-ton truck with a 5-speed and a nice FI engine that ran well but the transfer case and transmission housing were broken and besides everything was on the wrong side for the old straight axle suburban.

On of my largest assets is the 4-speed Suburban project. When I bought the ’90 ‘Burb it came with a malfunctioning automatic transmission. I hate automatics and malfunctioning ones even more so. The 700R4 works in Drive and Reverse but not in 1-2-3. The truck runs fine and it will tote a 3000-pound load without complaint but that boring automatic has got to go. It’s a rare Suburban that came with a 4-speed from the factory and even rarer to see a ½-ton version. I’ve only seen one 4-speed ‘Burb and it was ¾-on. This project keeps earning interest and I’ve been training a weather eye on Internet sale sites for a cheap, manual transmission, 4X4 GM truck to steal the guts from. I found a late model, 4X4-IFS 1/2-ton truck with a 5-speed and a nice FI engine that ran well but the transfer case and transmission housing were broken and besides everything was on the wrong side for the old straight axle suburban. The chalky blue, 1974 MG GT came with Tinfiny Ranch and was listed as an out building on the deed. This car was on the chopping block until I started reading about MG’s with Buick 215 cubic-inch aluminum engine swaps. I really have to stay off the internet. The Buick engine triples the horsepower, doesn’t weigh much more than the iron 4-banger it replaces and sounds cool as hell revved up to 6000 RPM. This is one asset I kind of wish was not in my Project Bank as I’ve never been that interested in cars. Still, it’s there waiting on me.

The chalky blue, 1974 MG GT came with Tinfiny Ranch and was listed as an out building on the deed. This car was on the chopping block until I started reading about MG’s with Buick 215 cubic-inch aluminum engine swaps. I really have to stay off the internet. The Buick engine triples the horsepower, doesn’t weigh much more than the iron 4-banger it replaces and sounds cool as hell revved up to 6000 RPM. This is one asset I kind of wish was not in my Project Bank as I’ve never been that interested in cars. Still, it’s there waiting on me. Tinfiny Ranch itself is a huge source of endless work, but beyond the physical plant The Ranch continues to deposit surprises into my Project Bank. This Merry Tiller project revealed itself as I was hauling away two, multi-panel garage doors. The doors sections were stacked with spacers in the popular rat-paradise fashion and I gave chase to a couple fat rats but they got away from me in the thick brush down by the ravine. The Merry Tiller looks like it will come in handy for the raised-bed vegetable garden (yet another deposit in The Project Bank) I’m planning for the back yard. The engine on the tiller is not stuck and being a Briggs & Stratton I’m sure it will run so I’m leaving it in The Bank for safe keeping.

Tinfiny Ranch itself is a huge source of endless work, but beyond the physical plant The Ranch continues to deposit surprises into my Project Bank. This Merry Tiller project revealed itself as I was hauling away two, multi-panel garage doors. The doors sections were stacked with spacers in the popular rat-paradise fashion and I gave chase to a couple fat rats but they got away from me in the thick brush down by the ravine. The Merry Tiller looks like it will come in handy for the raised-bed vegetable garden (yet another deposit in The Project Bank) I’m planning for the back yard. The engine on the tiller is not stuck and being a Briggs & Stratton I’m sure it will run so I’m leaving it in The Bank for safe keeping.