When I was 13 years old in Florida you could get a restricted permit at age 14. The restricted permit was a driver’s license that allowed you to drive as long as an adult was in the car with you. Assuming he/she wasn’t suicidal, the adult was supposed to keep an eye on your driving and coach you. An adult would help you pick up the nuances of parallel parking, rude hand gestures, and, in Dade County, gun fighting after minor traffic accidents. Needless to say, having an aged, creaking burnout sitting in the car fouling the air with the smell of stale urine cut down on motoring fun quite a bit.

There was a motorcycle loophole in the restricted permit system. If a motorcycle was less than 5 horsepower, and if you stayed off the major highways and didn’t ride at night, you could ride solo without adults helicoptering over your ride. It was wonderful. Obey these few rules and a kid could ride his motorcycle anywhere he pleased.

Motorcycles between 50cc and 90cc were right in the 5-horsepower wheelhouse but your average traffic cop couldn’t tell a 175 from a 50. Many bikes were rebadged to appear smaller displacement than they were. I never knew anyone in my circle of friends that got busted for riding a bike too big. Of course, you had to be reasonable about the subterfuge. A 50cc badge on a Kawasaki 750 wouldn’t fly.

Two months before I turned 14 the state upped the age for a restricted permit to 15 years old. The world ended that day. Massive volcanic eruptions, cataclysmic earthquakes, a steady rain of nuclear weapons bombarding the United States, nothing was as devastating to me as Florida’s stupid statute change.

I would have to wait an additional 365 days and I’d only lived 5000 days in total. The year dragged by. Endless days were followed by endless nights only to be repeated one after another. I had to attend yet another grade in school. I couldn’t wait to be done with public conformitouriums anyway and this stolen year of motorcycle riding made it all the more aggravating. The drip, drip, drip of time counted my heartbeats, counted my life ebbing away. I was inconsolable, miserable and the experience placed a chip on my shoulder for government that I have not shaken off.

Begrudging the failed clutch on my Husqvarna the other day I came to the jarring realization that I have owned the bike 9 years. I swear, I bought this thing not more than a couple days ago. I degreased the countershaft sprocket area to gain access and removed the clutch slave cylinder. From the inside of the slave I pulled out an aged, creaking o-ring that smelled of stale urine. The leak had allowed the clutch fluid to escape into the crankcase. Except for the missing 9 years the clutch repair went well.

Einstein was right; time is relative. From my 14-year-old perspective a year was an eternity. Now, as an adult I’m scared to close my eyes for fear that another decade will have passed by at light speed. Or worse yet, I won’t be able to re-open them at all.

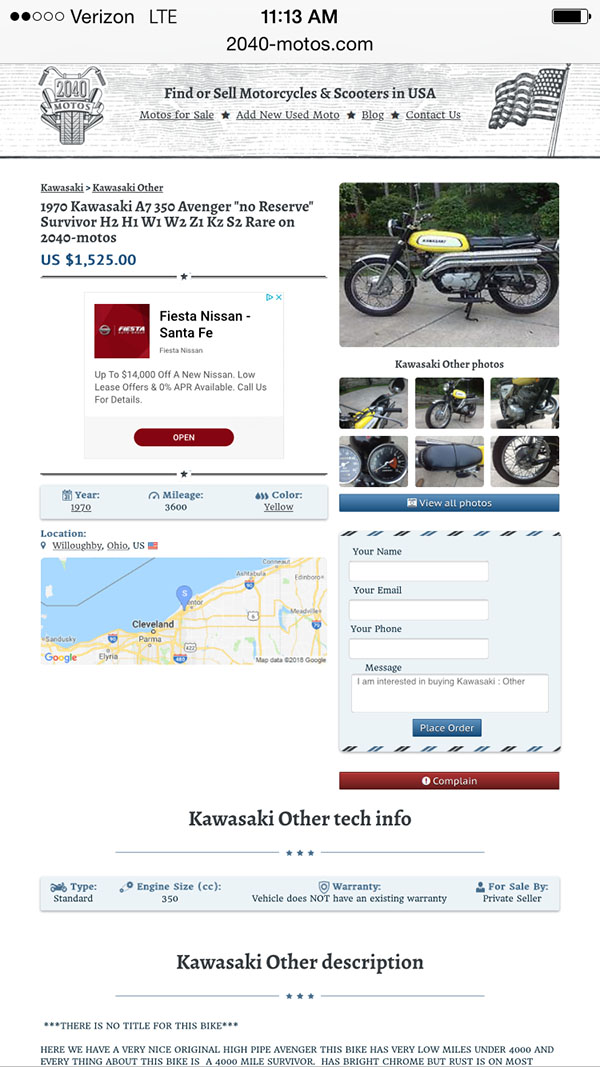

For me, the only knock on the A7 is that it may be too well made. I’m at the stage in my life where I don’t need a reliable motorcycle. New bikes are darn near perfect and perfection is boring. I search for the ever-elusive soul ride: Motorcycles that drip. The best motorcycles are the ones that leave you stranded; they turn any ride into a grand adventure. Besides, quirky flaws and secret handshakes appeal to my need to be special.

For me, the only knock on the A7 is that it may be too well made. I’m at the stage in my life where I don’t need a reliable motorcycle. New bikes are darn near perfect and perfection is boring. I search for the ever-elusive soul ride: Motorcycles that drip. The best motorcycles are the ones that leave you stranded; they turn any ride into a grand adventure. Besides, quirky flaws and secret handshakes appeal to my need to be special.

I don’t want to hurt anyone’s feelings but us oldsters are through. Our time has passed. No one cares if we like electric motorcycles or have range anxiety or just don’t like the silence. They don’t care. Bemoan the new kids all you want but we are dead-generation walking and the future always bats last.

I don’t want to hurt anyone’s feelings but us oldsters are through. Our time has passed. No one cares if we like electric motorcycles or have range anxiety or just don’t like the silence. They don’t care. Bemoan the new kids all you want but we are dead-generation walking and the future always bats last.