Most gift guides are hokey. Not this one. In keeping with our theme of shooting, motorcycles, and other interesting things, here are our recommended gifts and associated links. It’s good stuff. Purchase the things we recommend through the links we include here and you’ll ride faster, you’ll shoot straighter, you’ll weigh less, you’ll be better looking, and you’ll be one of the cool kids. (I took an advertising class and that’s the essence of what good advertising is supposed to do.) Without further ado (I have no idea what “ado” means, but if you say it during a wedding ceremony, you’re married), here you go.

Motorcycle Bungee Pack

Few things in our lives are as useful as a bungee cord, and it you want a nice gift for a motorcyclist, this Motorcycle Bungee Pack answers the mail. It includes an assortment of bungees and a cargo net, and it’s a sure thing whoever receives a gift like this will put it to good use.

A New BMW R 1250 GS

Well, sort of, although if any of our readers want to buy us a new BMW GS, that would be nice, too. Nope, what we’re referring to here are Maisto motorcycle models. They’re pretty cool, they’re high quality, and at approximately $20, they won’t break the bank. Maisto offers several other models, too, like the S1000RR you see at the top of this blog.

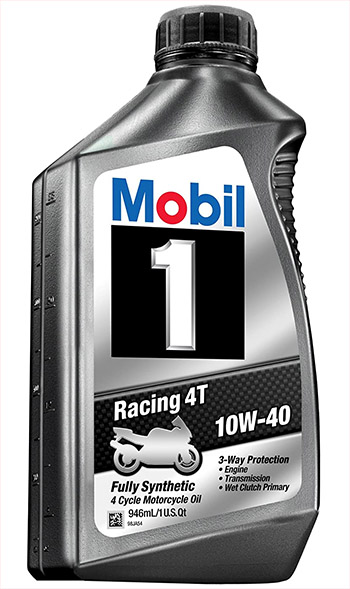

A Case of Mobil 1 Moto Oil

It doesn’t get any better than Mobil 1 4T synthetic oil for motorcycles. If you want to really impress someone, give them a case of Mobil 1 4T for their motorcycle. It’s only $79.00 and trust me on this, they will remember you every time they shift or blip the throttle.

Portable Jump Starter

We carried and used a portable jump starter on the Enfield Baja ride, and trust me, it was worth its weight in gold. There are several models available, and they start around $52. This Litake portable jump starter is small enough to carry on a motorcycle and it makes a great gift.

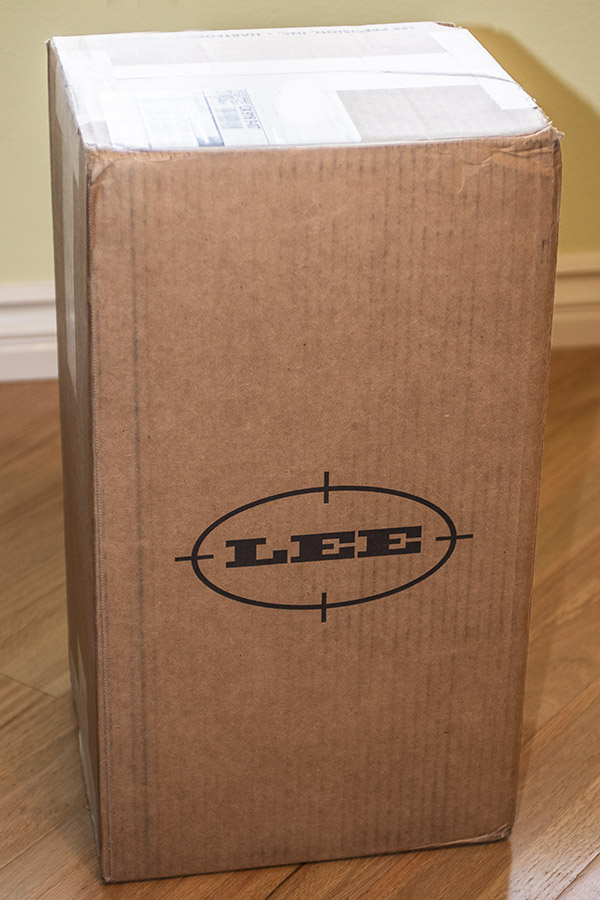

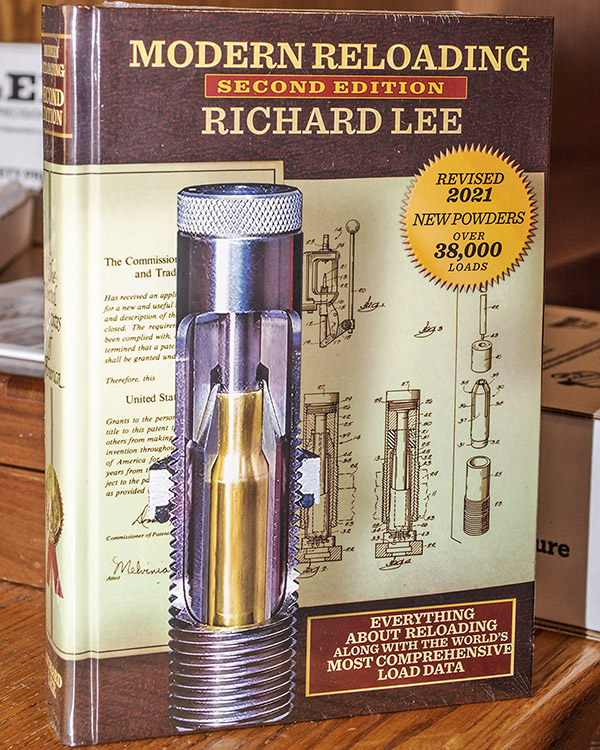

Lee Precision Reloading Gear

If you’re not reloading, your missing out on half the fun in the shooting sports. Making the decision to become a reloader can be a bit initimidating, but the major equipment manufacturers make it easy for anyone to start. If you want to start with a simple single-stage press, our advice is to go with Lee’s Challenger Kit for $229.

A single stage reloader is a good way to start, and the Lee Anniversary kit shown above is a good one. You can buy it directly from Lee or from Amazon.

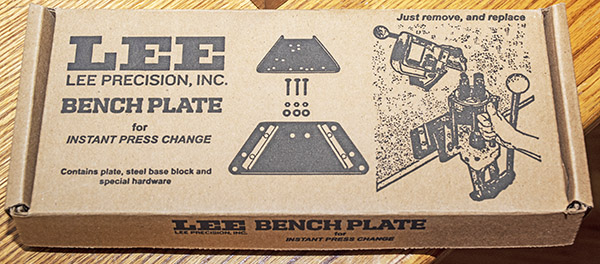

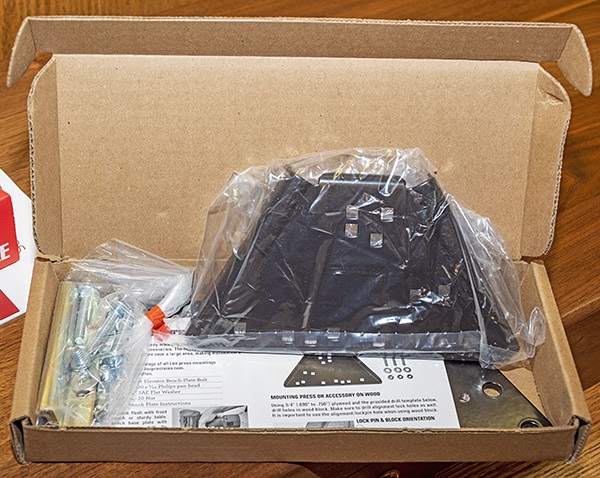

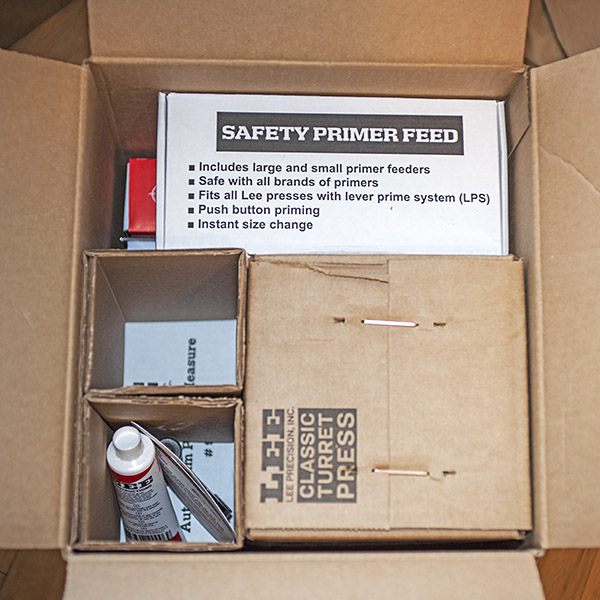

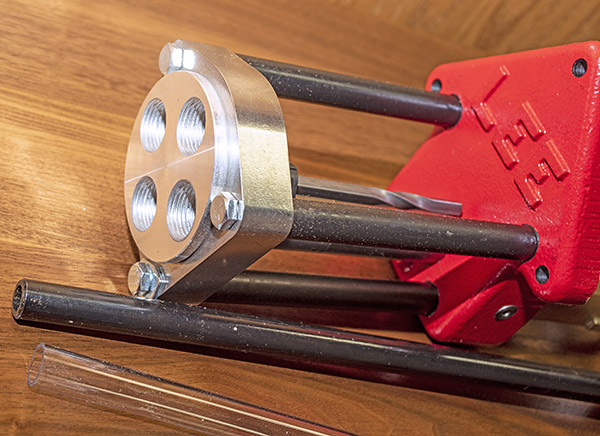

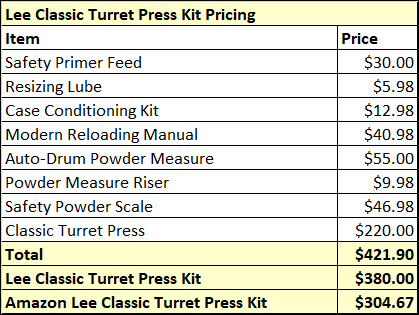

If the person you are giving the reloading kit to (which can be you, by the way) wants to reload at higher rates, you might consider the Lee Classic Turret kit for $380:

You can buy the Lee Classic Turret kit directly from Lee or from Amazon.

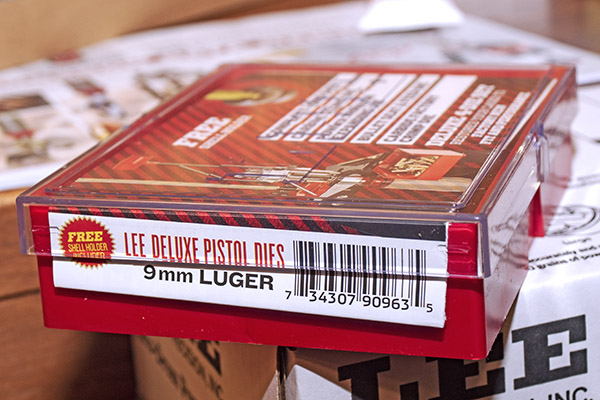

With either kit, the person receiving the gift will need a set of dies specific to the cartridge to be reloaded. We think Lee Precision makes the the best dies at any price (these are $78.00).

You can buy the above dies directly from Lee, or you can purchase them from Amazon.

Cool Watches

There are three or four you might consider. We’ve recently written about Casio’s G-Shock GD400 series. These are reasonably priced, they are incredibly accurate, they offer a world-time quick change capability, and a bunch of other features (illuminated dial, stopwatch, countdown timer, and more). Casio offers these for both men (at $89.95) and women ($53.95). I wear a G-Shock and so does Susie.

If you want something more formal, our recommendation is to get an automatic watch. There’s something elegant about a selfwinding mechanical watch, and Orient is one of most exclusive brands out there at a very reasonable price. Two personal favorites are the Moonphase (from $274.95 to $374.95, depending on color) and the Mako dive watches (at $147.95). I wear an Orient rose gold Moonphase when I’m trying to impress Gresh, and it’s a classy timepiece.

Toolkits

We very recently posted about a Wohngeist toolkit retailing for $2,895 (we’re not advising buying it, unless you feel a need to flush money down the toilet). A far better choice is any of several toolkits available at much more reasonable prices, like this one for $49.95. These make great gifts, and they won’t break the bank.

Buck Knives

Give someone a Buck knife, and you’ll have a friend for life. That’s how long the Buck will last, too. Buck makes a bunch of different knives, you can have them customized, you can have them engraved, or you can buy one off the shelf, so to speak. My personal favorite is the Buck 110 folder (shown in the photo below), but any Buck knife makes a wonderful gift. Buck 110 folders start at around $60.

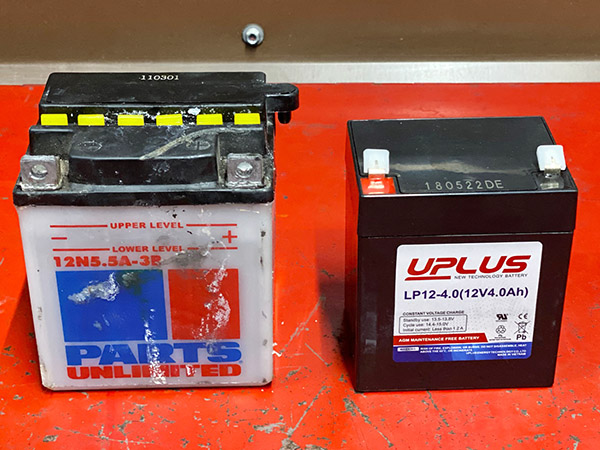

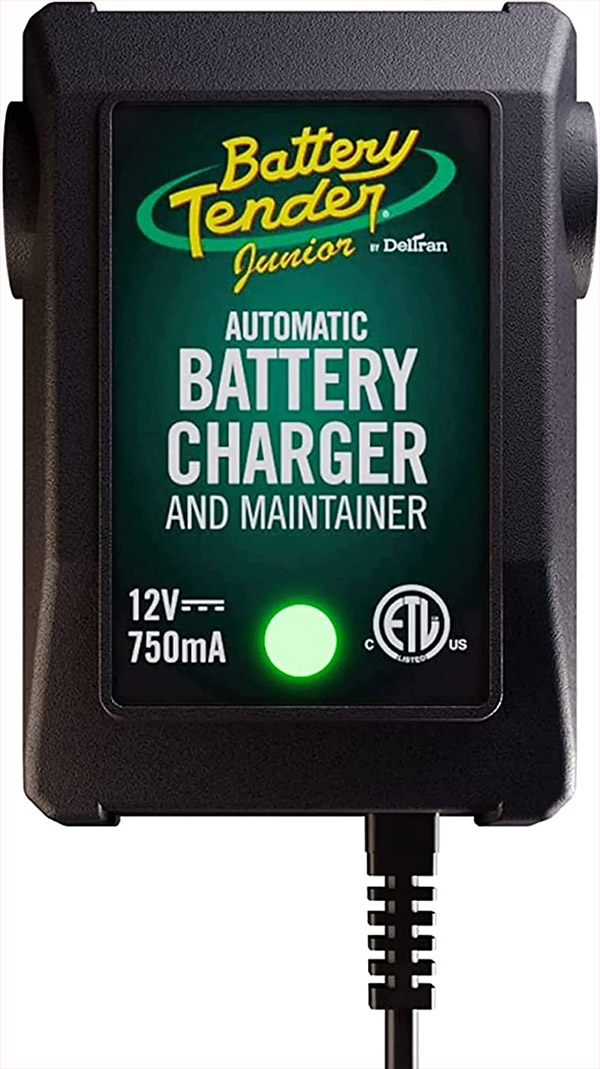

Trickle Me Elmo Battery Tenders

There are few things as useful to a motorcyclist than a Battery Tender. I’ve been using these for decades. A motorcycle with a topped-off battery runs better, and I’m coinvinced routinely plugging your bike into a Battery Tender extends the battery’s life. I regularly get between 4 and 6 years out of a motorcycle battery, and the Battery Tender is the reason why. These things are inexpensive ($39.95), and if they wear out, that would be news to me. I’ve been using mine for about 15 years and it’s still going strong.

Stop and Go Mini Compressors

Get a flat on your motorcycle out in the middle of nowhere and you’ll wish you had one of these, and so will all of your motorcycle friends. It happened to me more than a few times (on the Three Flags Rally, in China, and out in the boonies exploring the Mojave Desert). The Stop and Go Mini Compressor will pay for itself the next time you need to inflate a tire out there, and if you’re one of those folks who drops the air pressure when you see a dirt road, this will get you back up to street pressures quickly.

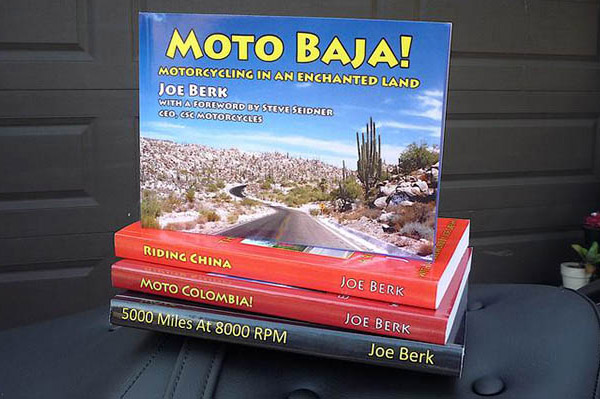

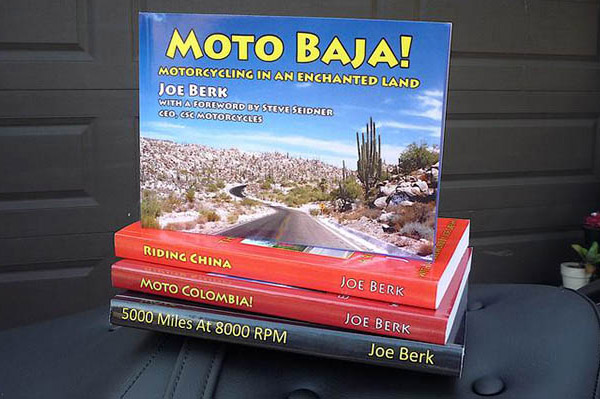

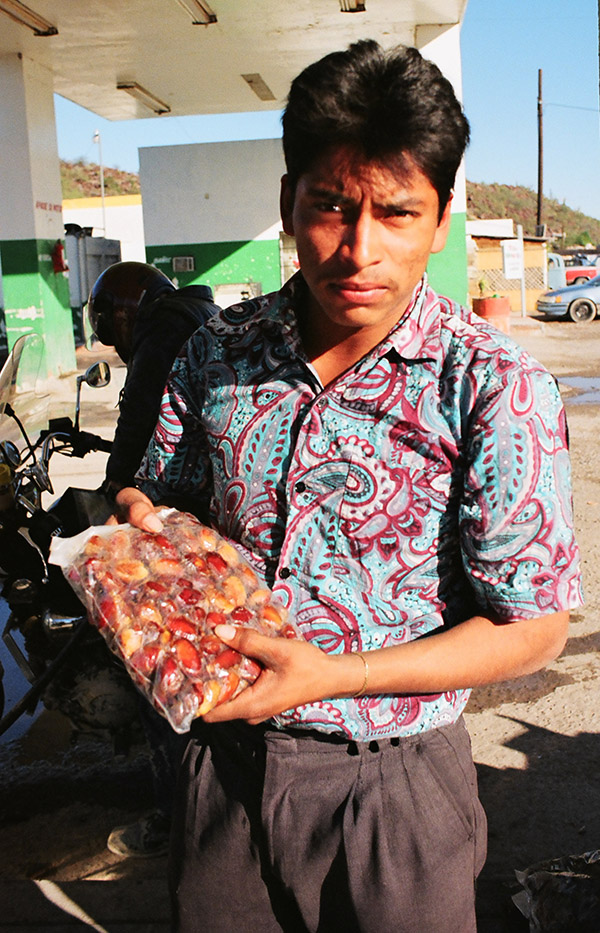

Our Motorcycle Books

Hey, what can I say. If you’re going to buy a motorcycle book, why not buy one I wrote? They’re inexpensive and folks say they’re pretty good. If you’re one of those folks tempted to wait for the movie instead of reading the book, don’t hold your breath. There were some preliminary discussions for a movie series, but when I suggested Leonardo di Caprio play me, the studio responded with Danny De Vito and talks broke down (so don’t wait for the movies).

Take a look at this selection of outstanding moto stories, pick the ones you’d like, and Mr. Bezos will have them in the mail to you muey pronto!

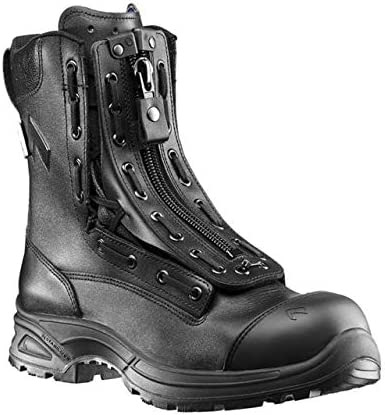

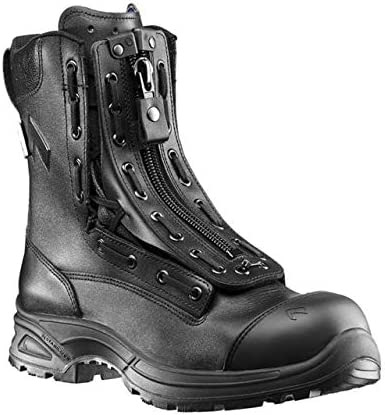

Haix Boots

The problem with motorcycle boots is they’re uncomfortable when you get off the motorcycle, especially if you have to walk anywhere. About 20 years ago I picked up a pair of Haix boots (a favorite of police, firemen, and other first responders) and I never look back. They are the only boots I wear when I ride a motorcycle. A pair of Haix boots lasts about 10 years, and they are extremely comfortable. They’re a bit more than most combat boots at $259.99, but they last a long time and the increase in comfort makes them well worth the price of admission.

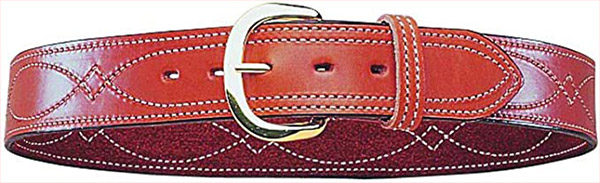

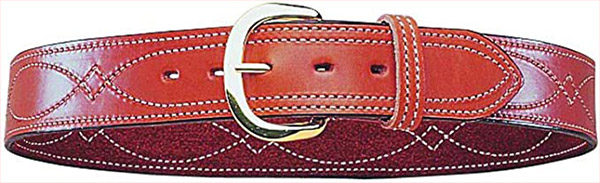

Bianchi Belts

I bought my Bianchi belt years ago and I think it is one of the best purchases I ever made. I wear it any time I need to wear a belt unless I have to dress up for a deposition or a formal event. The Bianchi is just plain comfortable, it doesn’t wear out, and for its intended purpose (supporting a holster) it is superb. You’d be surprised how much of a difference a good belt makes if you’re carrying a firearm (unless you already have a Bianchi belt, in which case you wouldn’t be surprised at all). But you don’t need to carry a gun to appreciate this belt. Like I said, I wear mine all the time. The Bianchi belt retails on Amazon for $66.02 (why they add the $0.02 is beyond me), and it’s worth every penny (even those extra two pennies Bezos tacks on).

Batdorf and Bronson Coffee

Batdorf and Bronson coffee is the best coffee in the world. Yeah, that’s my opinion, but try it and you’ll agree. Buy a selection of Batdorf and Bronson coffee for a holiday gift and you’ll make a friend for life.

So there you have it: Our 2022 gift recommendations. And don’t forget:

The best gift you can give to us is to continue clicking on those popup ads!

Never miss an ExNotes blog:

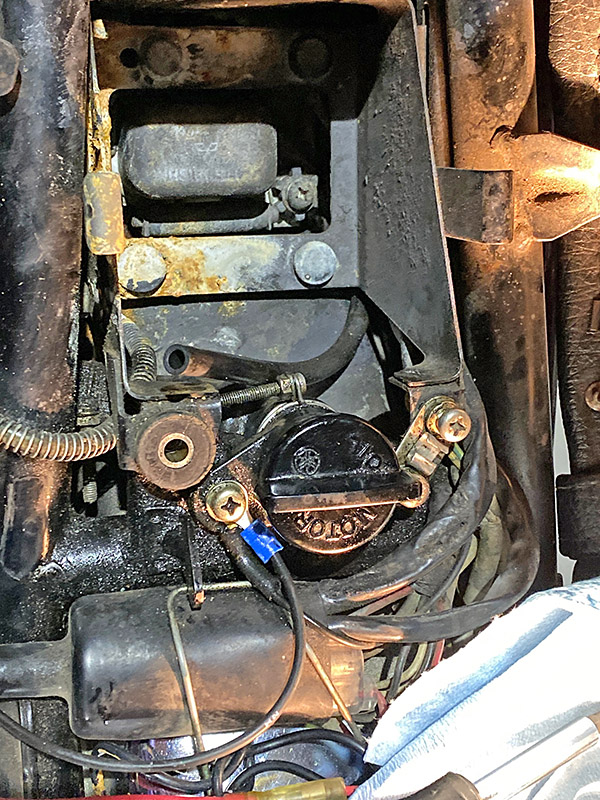

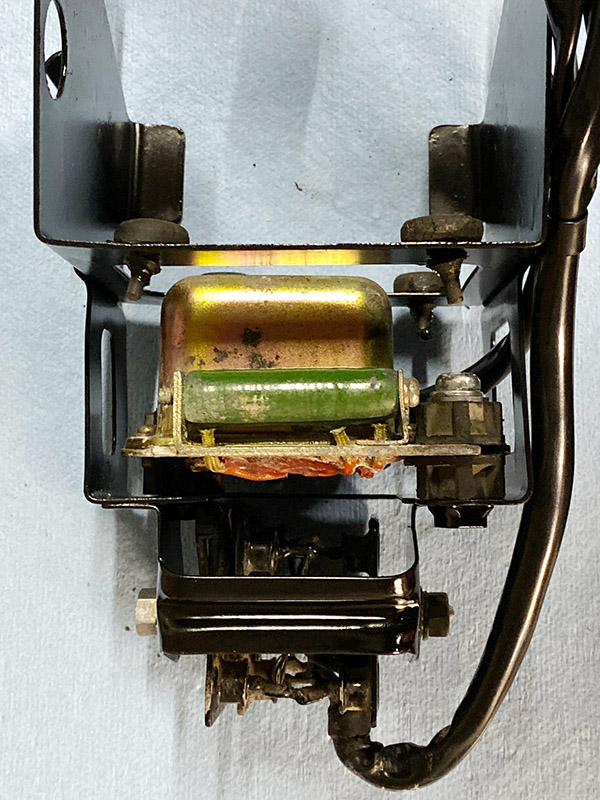

On of my largest assets is the 4-speed Suburban project. When I bought the ’90 ‘Burb it came with a malfunctioning automatic transmission. I hate automatics and malfunctioning ones even more so. The 700R4 works in Drive and Reverse but not in 1-2-3. The truck runs fine and it will tote a 3000-pound load without complaint but that boring automatic has got to go. It’s a rare Suburban that came with a 4-speed from the factory and even rarer to see a ½-ton version. I’ve only seen one 4-speed ‘Burb and it was ¾-on. This project keeps earning interest and I’ve been training a weather eye on Internet sale sites for a cheap, manual transmission, 4X4 GM truck to steal the guts from. I found a late model, 4X4-IFS 1/2-ton truck with a 5-speed and a nice FI engine that ran well but the transfer case and transmission housing were broken and besides everything was on the wrong side for the old straight axle suburban.

On of my largest assets is the 4-speed Suburban project. When I bought the ’90 ‘Burb it came with a malfunctioning automatic transmission. I hate automatics and malfunctioning ones even more so. The 700R4 works in Drive and Reverse but not in 1-2-3. The truck runs fine and it will tote a 3000-pound load without complaint but that boring automatic has got to go. It’s a rare Suburban that came with a 4-speed from the factory and even rarer to see a ½-ton version. I’ve only seen one 4-speed ‘Burb and it was ¾-on. This project keeps earning interest and I’ve been training a weather eye on Internet sale sites for a cheap, manual transmission, 4X4 GM truck to steal the guts from. I found a late model, 4X4-IFS 1/2-ton truck with a 5-speed and a nice FI engine that ran well but the transfer case and transmission housing were broken and besides everything was on the wrong side for the old straight axle suburban. The chalky blue, 1974 MG GT came with Tinfiny Ranch and was listed as an out building on the deed. This car was on the chopping block until I started reading about MG’s with Buick 215 cubic-inch aluminum engine swaps. I really have to stay off the internet. The Buick engine triples the horsepower, doesn’t weigh much more than the iron 4-banger it replaces and sounds cool as hell revved up to 6000 RPM. This is one asset I kind of wish was not in my Project Bank as I’ve never been that interested in cars. Still, it’s there waiting on me.

The chalky blue, 1974 MG GT came with Tinfiny Ranch and was listed as an out building on the deed. This car was on the chopping block until I started reading about MG’s with Buick 215 cubic-inch aluminum engine swaps. I really have to stay off the internet. The Buick engine triples the horsepower, doesn’t weigh much more than the iron 4-banger it replaces and sounds cool as hell revved up to 6000 RPM. This is one asset I kind of wish was not in my Project Bank as I’ve never been that interested in cars. Still, it’s there waiting on me. Tinfiny Ranch itself is a huge source of endless work, but beyond the physical plant The Ranch continues to deposit surprises into my Project Bank. This Merry Tiller project revealed itself as I was hauling away two, multi-panel garage doors. The doors sections were stacked with spacers in the popular rat-paradise fashion and I gave chase to a couple fat rats but they got away from me in the thick brush down by the ravine. The Merry Tiller looks like it will come in handy for the raised-bed vegetable garden (yet another deposit in The Project Bank) I’m planning for the back yard. The engine on the tiller is not stuck and being a Briggs & Stratton I’m sure it will run so I’m leaving it in The Bank for safe keeping.

Tinfiny Ranch itself is a huge source of endless work, but beyond the physical plant The Ranch continues to deposit surprises into my Project Bank. This Merry Tiller project revealed itself as I was hauling away two, multi-panel garage doors. The doors sections were stacked with spacers in the popular rat-paradise fashion and I gave chase to a couple fat rats but they got away from me in the thick brush down by the ravine. The Merry Tiller looks like it will come in handy for the raised-bed vegetable garden (yet another deposit in The Project Bank) I’m planning for the back yard. The engine on the tiller is not stuck and being a Briggs & Stratton I’m sure it will run so I’m leaving it in The Bank for safe keeping.

This was all fine with me. I was able to relax at the beach while still having the ability to leave the resort to take in some local food and sights. This included cigar stores, drooling over the 1950’s cars that were still in pristine condition, and of course soaking up some much-needed sun. The resort where I was staying was filled with Canadians and whenever they had those silly contests in the evening they would always ask where the person was from. I was tempted every time I was called upon to grab the microphone and loudly say “The United States of America,” and then I would revel in the silence that was sure to follow that statement. For once I listened to my Dad’s advice (Don’t do anything stupid, Mike). For the entire trip I identified as a Canadian from Toronto (I couldn’t say Montreal as I didn’t speak French) and I successfully avoided the temptation to say otherwise.

This was all fine with me. I was able to relax at the beach while still having the ability to leave the resort to take in some local food and sights. This included cigar stores, drooling over the 1950’s cars that were still in pristine condition, and of course soaking up some much-needed sun. The resort where I was staying was filled with Canadians and whenever they had those silly contests in the evening they would always ask where the person was from. I was tempted every time I was called upon to grab the microphone and loudly say “The United States of America,” and then I would revel in the silence that was sure to follow that statement. For once I listened to my Dad’s advice (Don’t do anything stupid, Mike). For the entire trip I identified as a Canadian from Toronto (I couldn’t say Montreal as I didn’t speak French) and I successfully avoided the temptation to say otherwise.

Bisbee, Arizona is a late 1880s copper mining town that turned in its explosives, shovels, and rock drills to grow into a more artistic town with historic hotels, quirky shops, and lots of festivals. Being that this tiny community is nestled in the canyons of southernmost Arizona (just minutes from the Mexican border), an idea struck me. I had not visited Mexico since February, and although this sounds crazy, I was craving tacos. Being this close to Mexico it felt almost a necessity to partake in a run to the border to extinguish my craving.

Bisbee, Arizona is a late 1880s copper mining town that turned in its explosives, shovels, and rock drills to grow into a more artistic town with historic hotels, quirky shops, and lots of festivals. Being that this tiny community is nestled in the canyons of southernmost Arizona (just minutes from the Mexican border), an idea struck me. I had not visited Mexico since February, and although this sounds crazy, I was craving tacos. Being this close to Mexico it felt almost a necessity to partake in a run to the border to extinguish my craving.