By Joe Berk

Rifles, that is…two Ruger rifles. I’ve written about them before, but it’s been a while since I shot either one and with the stream crossing to the West End Gun Club almost manageable these days (more on that later), I thought I would take them out to the 100-yard range. I shoot handguns regularly (at least a couple of times a week) on the indoor 50-foot pistol range closer to home, but there are times when the high-powered-rifle-on-a-football-field-length-range itch needs to be scratched.

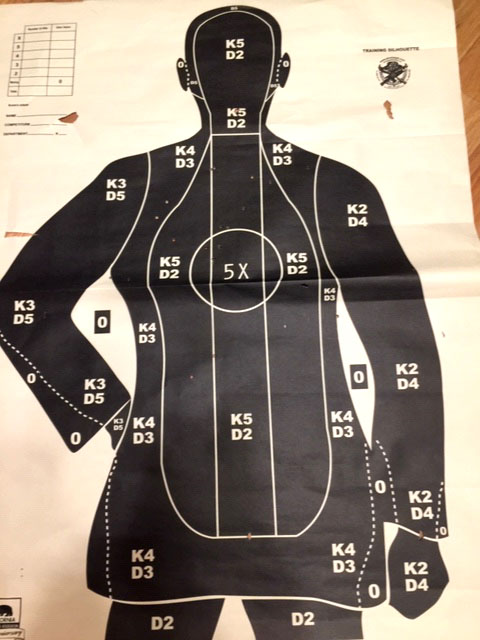

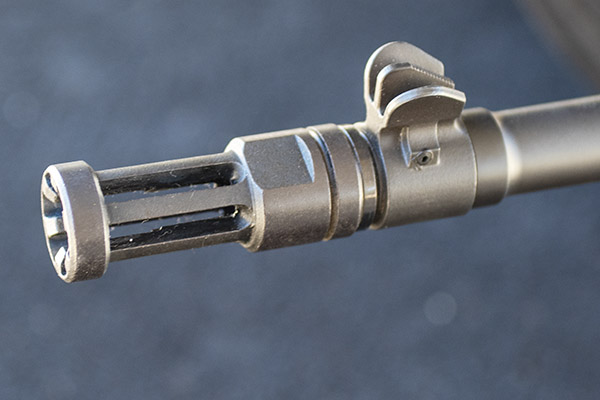

The two Ruger rifles in this article are two of my favorites: A Davidson’s Circassian-stocked Mini 14 (the one in the photo above) and the Ruger GSR (GSR stands for Gunsite Scout Rifle). The Davidson’s Mini 14 1was a 2009 offering with (as the name implies) a Circassian walnut stock. Back then the Circassian Mini’s $700 price seemed high, but I’ve been at this for a while and I know that when a gun’s price seems high it only means I’m buying too soon. The price will always catch up with the calendar, and that’s certainly been the case with this rifle. It originally came with two 30-round mags and a flash suppressor. California being what it is meant I couldn’t own the rifle as Ruger built it. I had to leave the 30-round mags with the out-of-state dealer, and because of the flash suppressor, it had to ship to the Class III dealer here in La La Land.

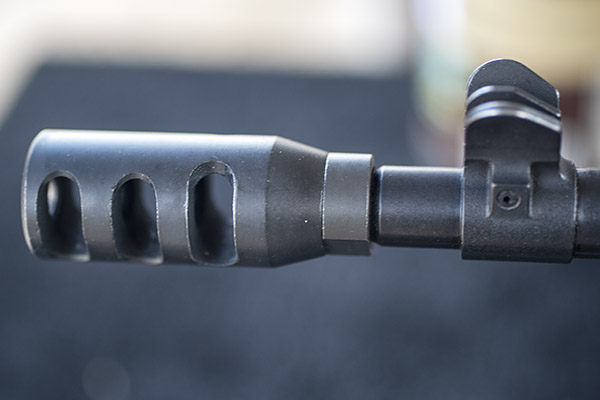

The California Class III dealer replaced the flash suppressor with a muzzle brake (which I think looks even more intimidating and I had to buy a 10-round La-La-Land-legal magazine for my Mini.

You might be wondering: Where can I get a Mini with a stock like this one?

The short answer is: You can’t. I watched the gun sale websites for months looking for a Davidson’s Circassian Mini 14 until I found one with nice wood (most had straight-grained, broomstick grade wood). When I saw the one you see here, I pounded (and I’m glad I did). You just don’t see Mini 14 rifles with wood like this one. It’s all mostly black plastic stuff on the range these days, which is almost a crime against nature.

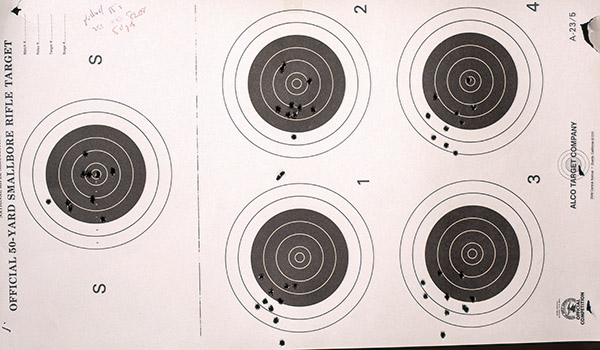

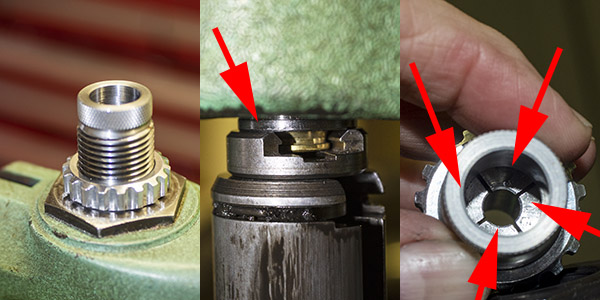

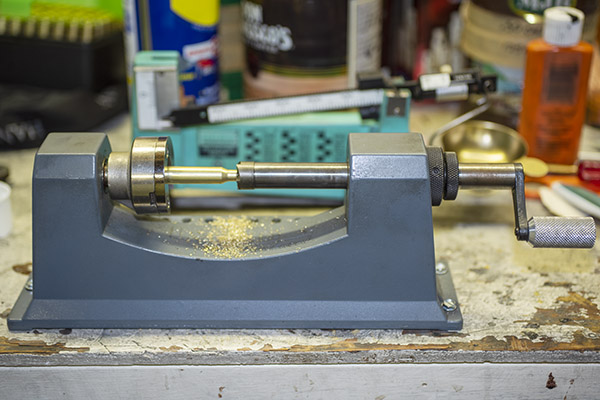

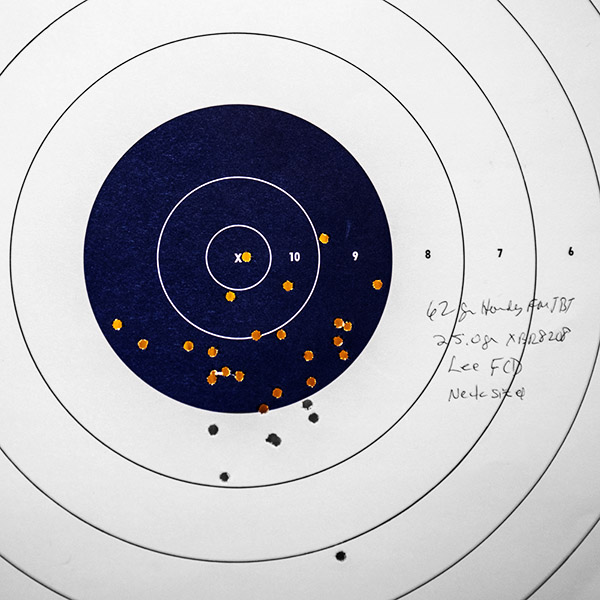

I’ve done a few mods to my Mini 14 to improve its accuracy, and I’ve detailed this in prior blogs (I’ve provide a link at the end of this article). The Reader’s Digest version is I’ve added a Techsites rear aperture sight to replace the Ruger sight, I’ve glass-bedded the action, and I’ve done a fair amount of experimentation to find the right load.

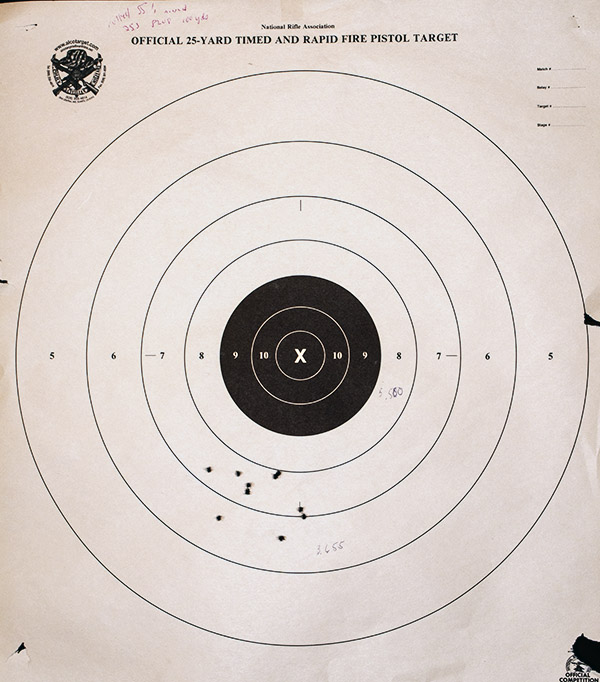

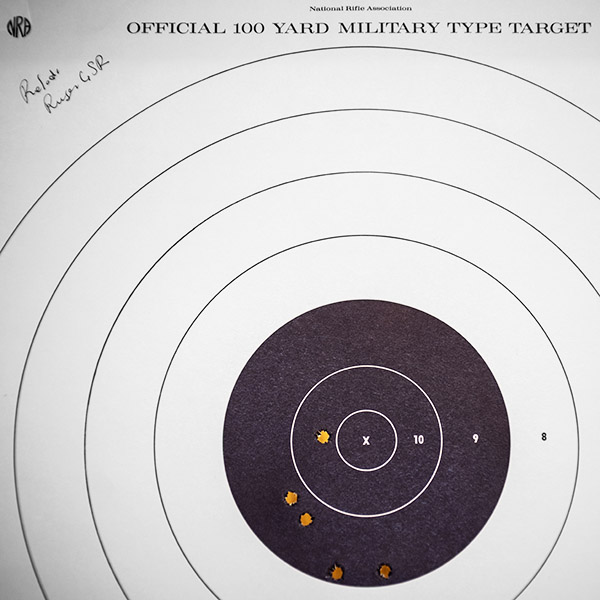

So how does the Circassian Mini 14 shoot? It does very well. I grabbed two loads: A full metal jacketed load with Hornady’s 62-grain bullet, and another with Hornady’s 55-grain V-Max bullets. You can see the results below.

The second rifle in this Tale of Two Rugers story is the Ruger GSR in .308 Winchester. This is an amazing (and amazingly accurate) rifle, but it didn’t start out that way.

How I purchased this rifle is kind of a funny story. I had oral surgery to start the process of installing two fake teeth, and the doc knocked me out with anesthetics. They warned me I would be in no shape to drive home, so good buddy Jim Wile volunteered to do the driving. Jim’s gone on to his reward (RIP, Jim). On the ride home, in a drugged but conscious state, I told Jim about this new GSR rifle Ruger had introduced, and we somehow managed to convince ourselves we each needed one. They say you should not buy guns when you’re under the influence. Like Hunter Biden, though, I didn’t heed that advice and Jim followed my lead.

The GSR is Ruger’s interpretation of the Scout rifle concept first put forth by a gun writer named Jeff Cooper. Cooper’s concept was a short-barreled rifle that would hold a scope in a forward location and make for a sort of do-anything long gun. Steyr built the first commercially available Cooper-inspired Scout rifle, and then about a decade later Ruger followed suit. Mossberg has one now, too (good buddy Johnny G has one). The Steyr is crazy expensive, the Ruger started out at a reasonable price but has since gone kind of crazy (along with everything else), and (in my opinion) the Mossberg is the best value (it’s a fine rifle and one I’ll probably own some day).

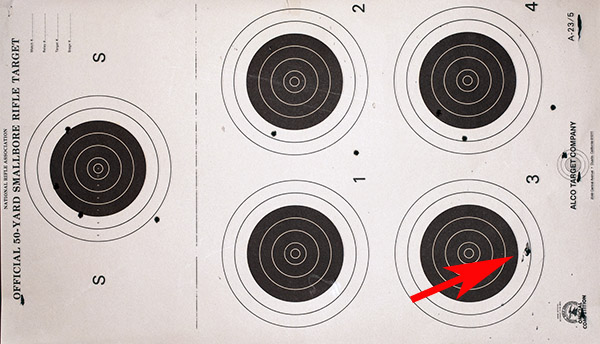

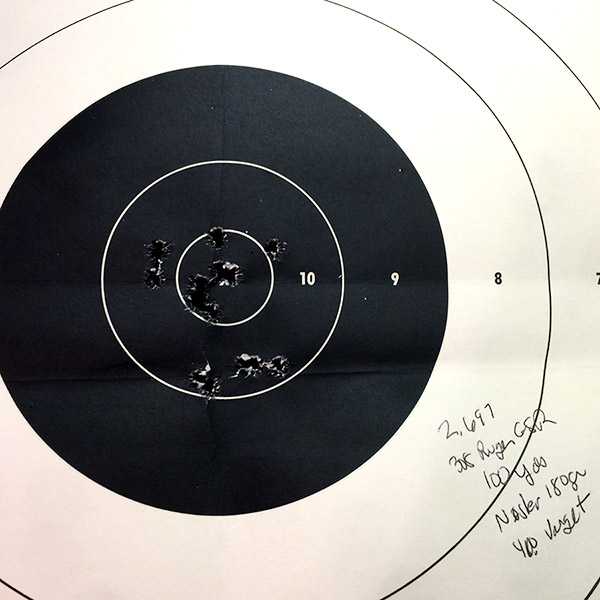

When I first took delivery of the GSR, it was a real disappointment. As had been the case with half the guns I bought in the last couple of decades, it had to go back to the manufacturer. The problem was that the rifle printed way to the right, and there wasn’t enough adjustment in the rear aperture to get it back to the point of aim. I returned it to Ruger, they greatly relieved the stock around the barrel, and I had it back in about a week. When I took it out to the range the same week it was returned, I was astonished by its accuracy.

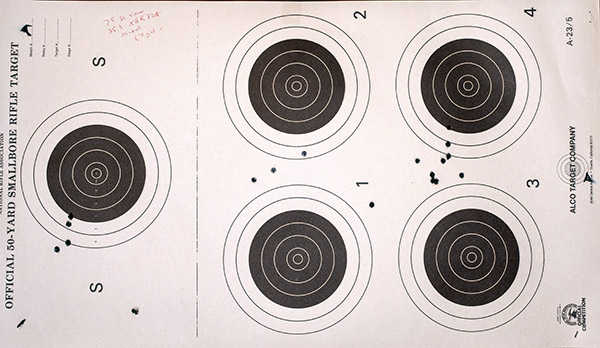

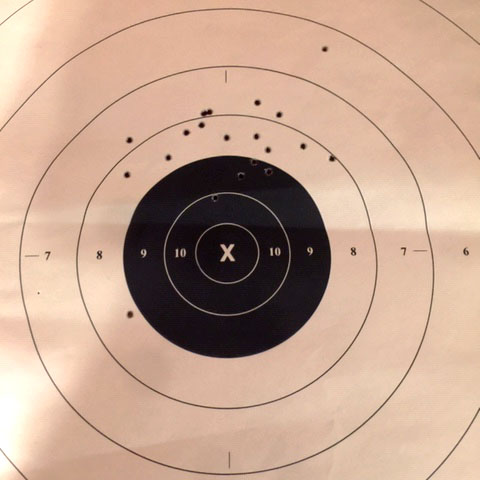

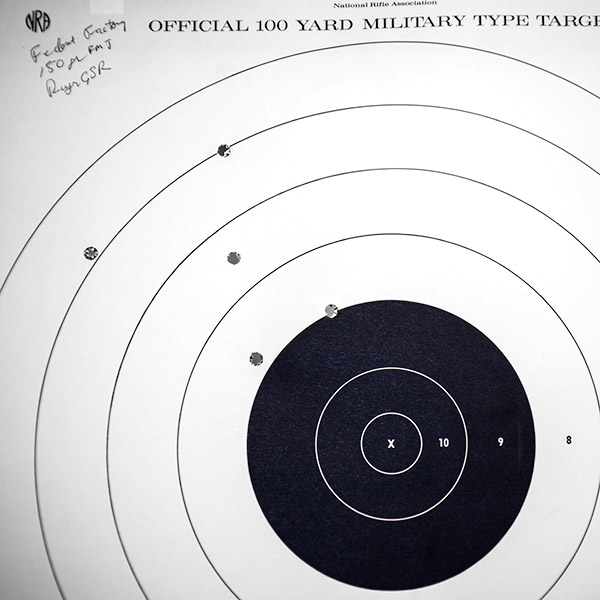

But that group above was then and this is now. I had not fired the GSR in a few years. I grabbed two loads for this rifle (a load I had developed for my M1A Springfield, and a box of Federal factory ammo with full metal jacket 150-grain bullets).

I only fired a couple of 5-shot groups at 100 yards with the GSR. It was getting late in the day, I was getting tired, I had not fired the rifle in a long time (shooting is a perishable skill), and I realized I wasn’t giving the rifle a fair shake.

That stream crossing I mentioned at the start of this blog? Lytle Creek flows across the dirt road going into Meyers Canyon, and it can be a real challenge at times. With all the rain and snow we’ve had this past winter, the reservoirs are full and the snow up in the San Gabriels is still melting. You may remember the blog I wrote about the time I high sided my Subie attempting a crossing. The stream is down a scosh since then, but it’s still not an easy crossing. Here’s a video I made on the way out on this trip after visiting the range with the Mini 14 and the Ruger GSR.

I’ll be shooting the GSR more in the coming weeks now that I’m back into the swing of shooting a .308 off the bench, so watch for more stories on it. I think I can do better than the groups you see above.

More stories on good times at the West End Gun Club are here.