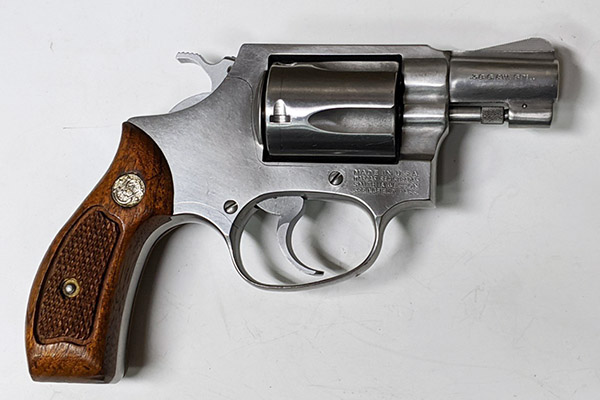

I visited with good buddy Paul up north last week, and while I was there he showed me a set of Altamont grips he had for his Smith and Wesson snubnose handgun. When I saw the grips it was love at first sight, and I had to have them for my TJ-customized Model 60. Paul was happy to oblige (thanks, Paul!), I came home with a new set of Altamont‘s finest, and they promptly went on the Model 60. The Model 60 now looks like a scaled-down version of the big .45 ACP Smith & Wesson Performance Center Model 625, and I had to grab the shot you see above. The 625 wears custom grips, too, but that’s a story for another blog.

There’s no question I’ve gone overboard in getting grips for the Model 60. It came with the stock checkered walnut grips (the original equipment on this handgun), as well as a set of Pachmayr rubber grips. The Pachmayrs would have been better for shooting, but I wanted a set of smooth rosewood grips and I found them on Ebay. They looked great, but they were painful to shoot.

The problem with the stock walnut grips and the Ebay rosewood grips is that my little finger gets under the grip. The recoil from the little Model 60 is significant (as we engineers like to say, f = ma), and it would pound my pinkie every time I fired it. Think about putting your pinkie sideways on a table and having someone whack it with a hammer, and you’ll have a pretty good idea what shooting this little snubbie was like.

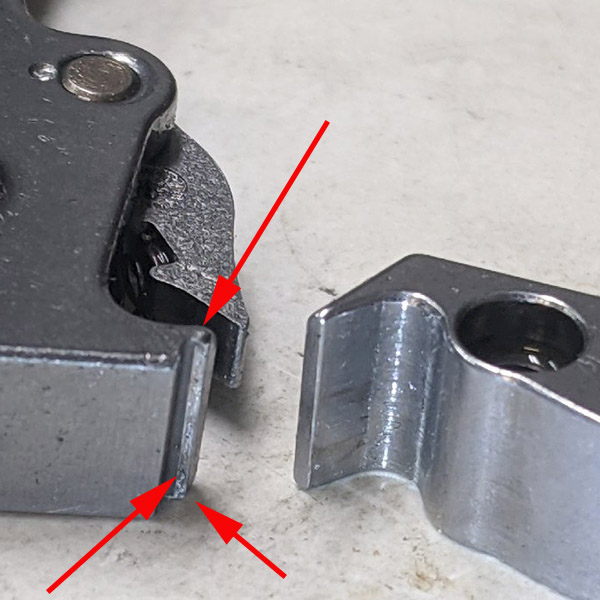

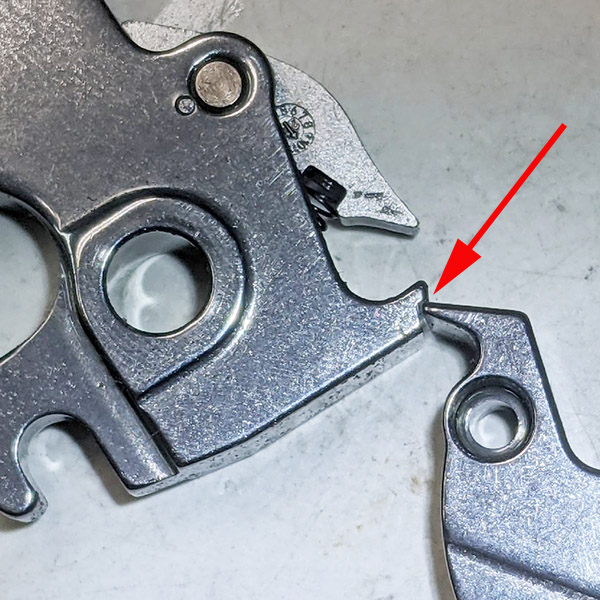

All that’s changed with the Altamont grips Paul provided. Take a look. They’re beautiful.

The new Altamont grips are extended just a bit below the frame and they have finger grooves. It keeps my pinkie from getting underneath the frame, and with the new grips the Model 60 just feels right in my hand.

These new Altamont grips have a much better feel to them. The wood-to-metal fit is way better than with the stock grips (the grips exactly contour to the Model 60’s frame, unlike the OEM grips). The next obvious question, and the one that really matters is this: How did the Model 60 shoot with the new grips?

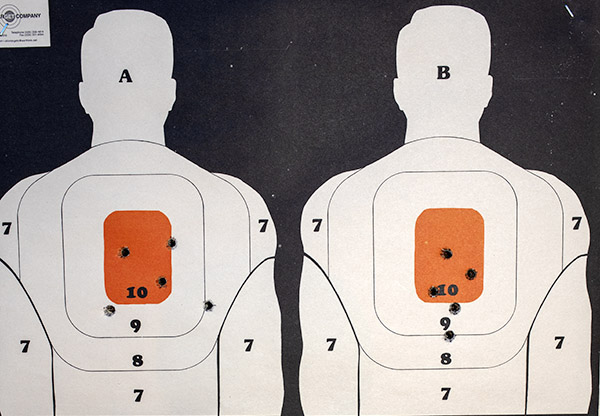

In a word, it was amazing. The new Altamont grips completely changed the character of the Model 60. First, a couple of shots of the Model 60 on the range:

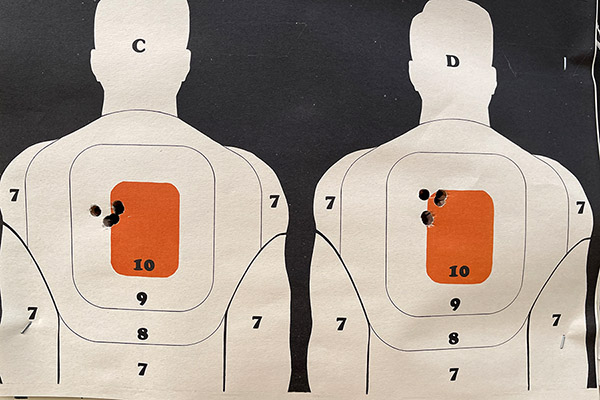

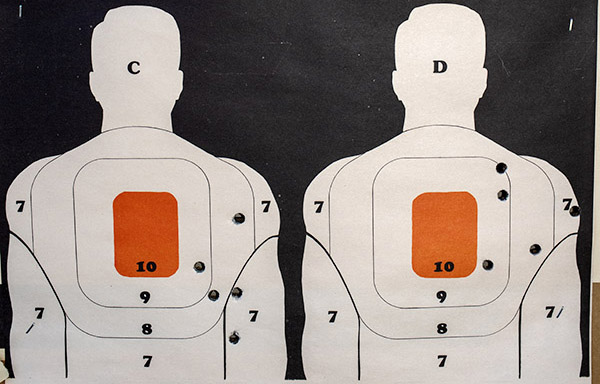

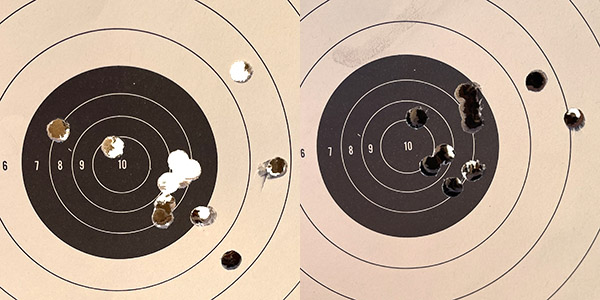

And here are two targets I shot at 15 yards (45 feet). One has 10 shots on it; the other has 12 (each had two cylinders of 5 cartridges, and I had a couple left over to finish the box).

Several things are amazing about the above targets. The first is that it was windy as hell out on the range this morning, and even though I was shooting with both hands from a bench, I could see the sights swimming around as the wind gusted. The second is that the groups are dramatically tighter than they had ever been before with this handgun. And the third is that the revolver shot almost exactly to point of aim. I was holding at 6:00 on the 50-foot slow-fire NRA targets you see above. My load was the tried and true .38 Special target load: 2.7 grains of Bullseye propellant with the 148-grain Hornady hollow base wadcutter. Before, with the OEM and rosewood grips shown above, this same load shot a good 12 inches to the right of the point of aim, and the groups were huge. Evidently, as the revolver discharged, it was rotating to the right in my hands with those much smaller grips (and beating the hell out of me in the process). The Altamont grips brought the point of impact essentially in line with the point of aim and just a bit high, which is what I want in a handgun.

You may recall from a recent blog that I have a load development test planned for the Model 60, and I’ll be firing the cartridges I loaded for it within the week. I was up north on a secret mission last week and I didn’t get to shoot during that time. I recently read that if you go 72 hours without firing a handgun your skills deteriorate. I believe that, and I wanted to get in a little shooting before I shoot for group size. Hopefully, the Santa Ana winds through the Cajon Pass will die down, conditions will be right, and I’ll get to do some real accuracy testing in the next few days. You’ll get the full report right here. Stay tuned, my friends.

More Tales of the Gun are right here!

Never miss an ExNotes blog: Subscribe here for free: