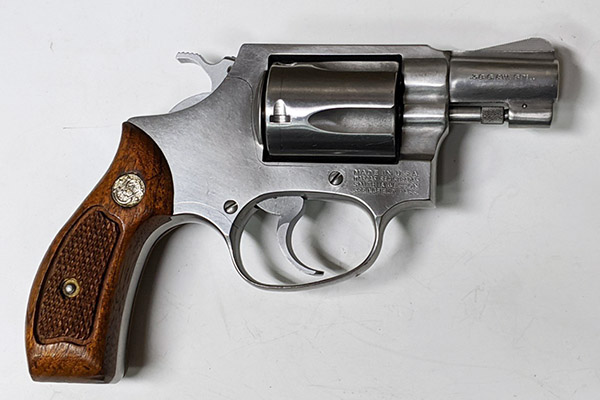

The 1911 is an all time favorite handgun for me (and a lot of other people, too). I’ve owned several 1911s over the last few decades, I carried one in the Army, and I enjoy shooting them. One of the best I’ve ever owned is a bright stainless steel Series 80 Government Model I bought new back in the mid-1980s. Mine has been customized by good buddy TJ (of TJ’s Custom Gunworks) and it’s the one you see here. I have no idea how many rounds I’ve sent downrange with this gun, but it’s been zillions. Maybe even gazillions.

TJ’s Custom 1911 Touches

My bright stainless 1911 has had a number of TJ’s custom touches. The fixed Millet sights are probably the most obvious.

TJ polished and ramped the gun’s internals so it will feed anything, he added a Les Baer match grade barrel, and I had him engine turn the chamber (I love the look).

The original Colt front sight wouldn’t stay put on my 1911 (probably because of the number of rounds I was cycling through it), and after having the front sight restaked twice, I knew something more permanent was required. The Millet red ramp from sight has two stakes, they are each larger than the single Colt front sight stake, and TJ JB-welded them from underneath after staking. They are on there for the duration. A lot of folks prefer a dovetailed front sight and that would have worked, too, but I’m partial to these no-longer-made Millets. I just like the look.

The rear sight is a fixed Millet dovetail and it has a bright white outline that works well with the red ramp front. I’m not normally a fan of gimmicky sight doodads like red ramps and white outlines, but these just flat work. They’re quick to acquire and they put the bullets where I want them to go. Millet sights are no longer in production, but they are some of the best ever made and TJ keeps a stash in stock for his customers. I imagine he spends a lot of time on Ebay hunting for these things.

One other thing TJ did on my 1911: He fitted the extractor. It was very rough as delivered from Colt and difficult to remove for cleaning. Now (after TJ’s magic touches) it inserts and removes easily, and extraction is flawless.

1911 Accuracy

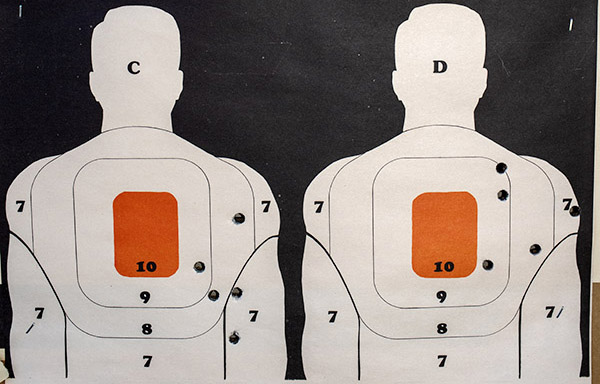

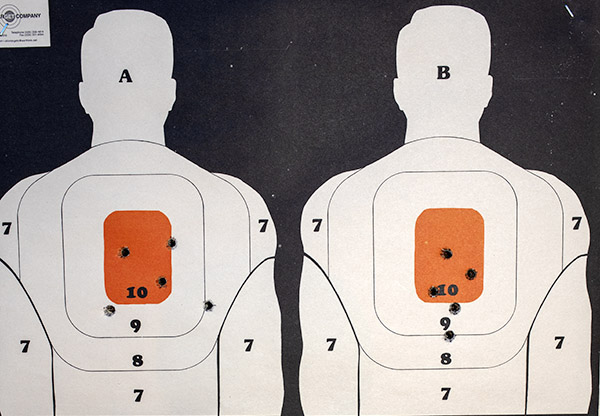

Close enough for government work, most folks would say, and maybe that’s so. When I slow down and do my part, I can tear one ragged hole at 50 feet with my 1911, and that’s good enough. If I’m shooting for fun with a bit of speed, it’s not problem to put an entire box of ammo through one big ragged hole with the odd flyer or five like you see up top.

The Millet sights print where I want them to, and I like the simplicity of fixed handgun sights. It’s a good setup.

Getting a Grip

My 1911 didn’t need a trigger job, and TJ recommended not trying to improve the trigger after he felt it. The gun came with the rubber Pachmayr-type wraparound grips from the Colt factory, and I added a Pachmayr rubberized rear grip housing. Those two items (the rubber grips and rear grip housing) are, in my opinion, as good as it gets in the 1911 game. I don’t think that rear grip housing is available any more. I wish I had bought a few extra when Pachmayr was still making them.

Appearance Is Everything

I’m not normally a shiny objects kind of guy, but when I first saw my bright stainless 1911 in that gun store 35 years ago, I knew I had to have it. The gun just looked cool and it’s a conversation starter. It’s easy to pick up minor scratches that I can see before other folks do, but they come right out with a bit of Flitz (a superb stainless steel polish) and a little elbow grease.

My Three Favorite .45 ACP Loads

The target you see at the top of this blog? That’s 50 rounds at 50 feet with one of my favorite loads for this and any other 1911 I’ve ever shot: 5.0 grains of Bullseye under a 185-grain cast semi-wadcutter bullet. I’ve got a couple of other favorite loads, too. One is the 230-grain cast roundnose over 5.6 grains of Unique (that load is 100% reliable in any 1911). Another for target work is 4.2 grains of Bullseye and a 200-grain cast semi-wadcutter. All three loads are as reliable as taxes going up under a Democrat, and they all work with the same recoil spring. In my case, that’s the spring that came with my Colt 1911.

If you’re interested in learning how to reload .45 ammo, here you go:

Reloading Part I

Reloading Part II

Reloading Part III

Reloading Part IV

Sign up for free!

We have more good stuff on our Tales of the Gun page, and if you enjoyed this piece, you might take a look.