I’ve dropped a lot of usable content on Facebook without thinking about it. Good stories that would have made excellent topics for an ExhaustNotes.us blog post and I’ve screwed around and published them on Facebook’s Anti-Social Network. To what end? All it does is supply the buoyant pontoons that support a miserable, never-ending political tussle on my Facebook feed. My Chase Harper magnetic tank bag is a perfect example. Why haven’t I written a product review on this thing?

Until John Burns over at Motorcycle.com brought up tank bags I had completely forgotten I had one. I bought the Chase Harper 650 the day Berk and I left for our 650/500 Royal Enfield Baja trip. Neither Royal Enfield was set up with luggage so we strapped our gear on the bikes as best we could. I started out on the 500cc Bullet and I had so much junk to carry I used a backpack to hold some of it.

I’m a proponent of letting the motorcycle carry as much weight as possible. Slinging 20 pounds of junk onto your back and then pounding on city streets is not smart or sexy. My back was already hurting. We were working our way south to pick up a freeway when I called out to Berk, “Is there a motorcycle shop around here? I need to get a tank bag.”

“Yeah, follow me.” I followed Berk through the nondescript Californian sprawl and we arrived at a motorcycle accessory shop that was not named CycleGear. The shop guys came out and ogled the (at the time a new model not yet sold) Royal Enfield 650. We shot the breeze for a bit and then went inside to look at tank bags. Which didn’t take long because they only had one in stock: the Chase Harper 650.

The Model 650 is as plain as you can make a tank bag. It has a few zipper compartments and four strong magnets to hold the thing to your tank. Nothing expands or is special. Chase Harper is proud of their motorcycle products and prices them accordingly. The thing was like 90 dollars! As it was the display model, kind of dusty and missing the box and paperwork I asked the guys for a discount. No deal.

Berk started telling them how we were famous motojournalists. The clerks shook their heads, neither having heard of or read our stuff. I showed them a few tired old Motorcyclist Magazine stories on my cell phone and they seemed really interested but would not budge on the price. “We’ve already reduced the price on that bag, we can’t go any lower.” I bet Peter Egan could have gotten the price down. The fastest way to end this ego shattering indignity was to fork over the money and haul ass as fast as we could.

The bag was a great relief for my back. It held my camera, wallet, phone and enough stuff that I could survive a day or two on the hoof. Whenever Berk and I went into a store or restaurant I took the bag with me. The magnets make that so easy. I didn’t like that the bag had no rain cover. Those soulless misers at the motorcycle shop not called CycleGear said it was rain resistant. Whenever a motorcycle gear manufacturer says a product is resistant to rain you can take that to mean the damn thing is a sponge. I mean, anything that doesn’t dissolve like sugar when it gets wet could be described as resistant to rain.

As it turns out we didn’t hit any rain on our ride through Baja and the tank bag worked out perfectly fine. I got the 650 Royal Enfield up to an indicated 115 miles per hour and it stayed put like it was made to do 115.

In all the time I have owned the C-H bag I never really looked it over too closely. I didn’t see any straps for using the bag like a backpack. This is a common feature on tank bags. It wasn’t until Burns’ brought up tank bags on Facebook that Steve, another C-H 650 user told me that the straps were hidden in a zipper compartment under the grab handle.

And they were! Well hidden, I wonder if I the shop not named CycleGear had given me the original paperwork for the 650 would I have found the straps sooner? Probably not: I would have tossed the paperwork anyway. I’m a rebel, man.

The interior of the C-H 650 is plush, deep red. I feel like I have a bordello between my legs whenever I open the lid. Well padded, my camera gear survived Baja’s bumpy roads unscathed.

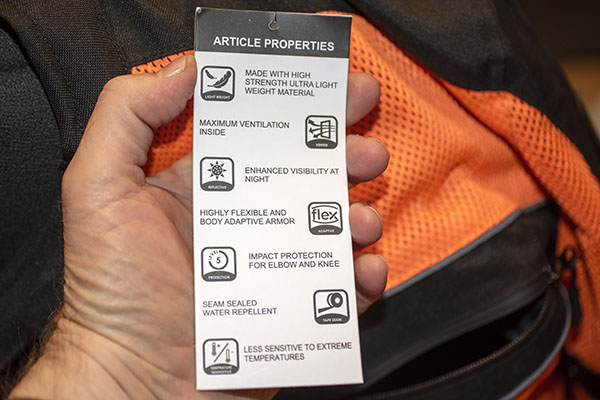

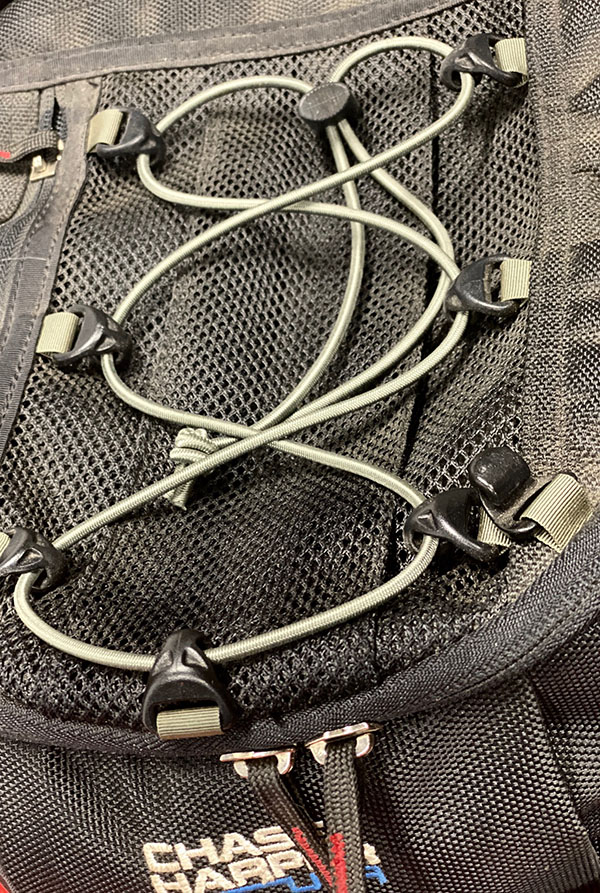

The lid of the 650 has quite a few features. There’s a bungee cord crisscrossing the top to hold odd shaped bits. Behind the mesh map holder there is yet another zipper for papers and what not.

Finally, there is a front-opening pouch with a red plastic liner that might keep something dry depending on how much the zipper leaks. I haven’t used any of these little hidey-holes so I can’t say if they are worthwhile. I toss everything into the main compartment.

The backside of the C-H 650 is not covered in super soft material. It’s more like vinyl. I had no tank scratches using the 650. There is one clip on the front and two clips on the back that I imagine could be used for strapping the bag to non-metallic gas tanks. I did not get the parts that would affix the bag to a non-metallic tank. They might be an extra cost item or you-know-who lost them at that shop not named CycleGear.

Overall I’m happy if not ecstatic with the Chase Harper tank bag. Just remember to bring plastic bags to protect your stuff in the rain. It did the job I needed it to do for much more money than I thought it should. For only having one, dusty tank bag the shop not named CycleGear did ok. My last tank bag lasted 10 years. This one looks sturdy enough to go the same distance.