I visited Chiriaco Summit and the Patton Museum last week (we’ll have a blog on it soon) and it was awesome. But wow, was it ever hot. As in 111 degrees when we left, and that’s not an unusually warm day out there in the Sonoran Desert. The next town over is called Thermal, and a little further north there’s this place called Death Valley. Death Valley recorded a whopping 131 degrees three weeks ago. Sensing a pattern?

Yeah, it gets warm in these parts, and in other parts of the world as well. Hot weather is not ideal riding weather, to say the least, but sometimes we find ourselves riding in shake and bake conditions. I’ve done it. I rode a 150cc scooter all the way down to Cabo and back in Baja’s hottest month of the year (September, when it was well over a hundred degrees every day). It was humid down there, too, once we crossed over to the Sea of Cortez side of the peninsula. We were literally entering the tropics as we crossed the Tropic of Cancer. Whoa, that was rough riding!

When we did the Western America Adventure Ride with CSC and the guys from Zongshen, we rode through the same corridors described earlier above, riding across California and the Mojave Desert, through Joshua Tree, and on into Arizona with temps approaching 110 degrees. That was brutal riding.

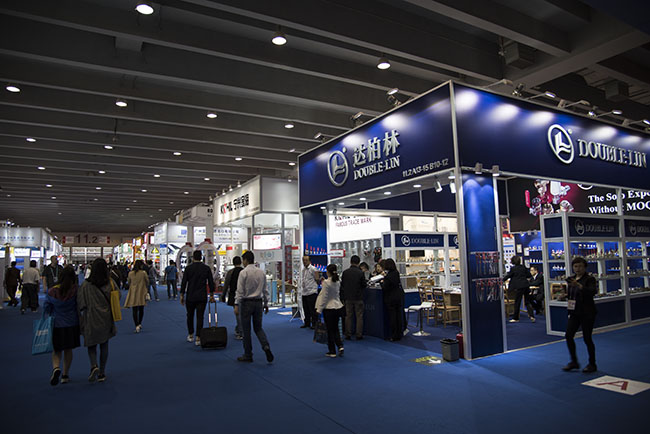

The ride across China that Joe Gresh and I did had similar challenges. It started out hot, then it got cold as we rode into the Tibetan Plateau, and then it became brutally hot and humid as we descended into central China and rode east to Qingdao. That was a 38-day ride, and I’d guess it was well over 100 degrees for at least 30 of those 38 days.

The risk, of course, is heat stroke, and it’s often not the kind of thing you can feel coming on. You’ll think you’re okay one minute, and the next you’re waking up in an emergency room wondering what happened. If you start to feel a headache while riding in hot weather, you are already perilously close to heat stroke. You need to stop, drink copious amounts of water, and get some shade. The better approach, though, is to not let yourself get anywhere near that condition, and that’s what this article is all about.

It almost seems like heresy to say it, but my first bit of advice about riding in hot weather is: Don’t. Given the choice, postpone the ride. But let’s assume that this is not an option, as was the case for each of the rides mentioned above. Okay, then…here’s my guidance on the topic.

12 Hot Weather Riding Tips

One: Don’t ride naked. I’m not trying to be funny here, and I’m not implying you might be the kind of person who would go down the road wearing nothing at all (although there is that story about Gresh riding around with only a bathrobe). Nope, what I’m talking about is not shucking your safety gear. You have to wear it. All of it. ATGATT. All the gear, all the time. You can’t peel it off just because it’s hot. It’s saved my life.

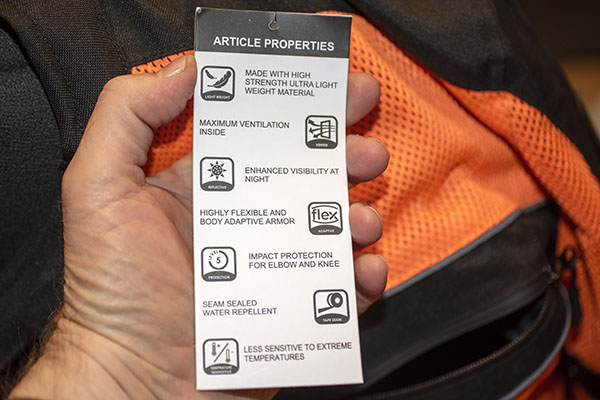

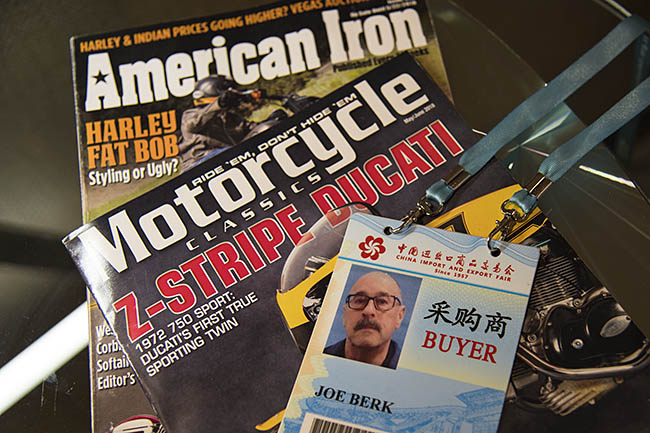

Two: Wear a good mesh jacket. These are available from several sources. I have a Viking Cycles jacket I’m wearing these days and it works well. I wore a Joe Rocket mesh jacket on the ride across China and it made a big difference. You can get them from Viking Cycles, CSC Motorcycles, British Motorcycle Gear, and other sources. Trust me on this…you need a ventilated jacket for riding in hot weather. EDIT: We’re getting interesting comments advising not wearing a mesh jacket in hot weather. Make sure you read the comments below, and for those of you who responded, thanks very much!

Three: Use a cooling vest. These things actually work, but they’re not as easy to use as it sounds. They don’t work for long, but they work. The idea is you soak them, and then wear them under a jacket. The airflow causes the water in the vest to evaporate and that cools the vest and you. I’ve found that on really hot days these vests need to be remoistened about every thirty minutes, but you should be stopping that often anyway (more on that later). It’s the remoistening part that I don’t like. It seems like they take forever to soak up water when you remoisten them. I’ve found it easer to just get my clothes wet (see the next point below).

Four: Go soak your head (and everything else). Don’t laugh; I’ve done this. On the Baja ride I mentioned above, it was so unbearably hot that we took to pouring water down the inside of our riding jackets and inside our helmets at every stop. We became rolling evaporative coolers. It helped.

Five: Change your riding hours. On the really hot days, I like to hit the road at 0:Dark:30. Get out and get a hundred or so miles in before it gets unbearably hot. You’d need good lighting on your bike to do this (I generally don’t like to ride at night, but I’ll make an exception when I know it’s going to be hot). This is difficult to do when riding in a group because it’s hard to get everybody moving that early. If it was just me and Gresh or Welker, we’d leave way early and get in a couple of hours of riding (or more) before the sun comes up.

Six: Drink a lot of water. The problem with riding in high temperatures is you don’t realize how much water you lose through perspiration. My advice is to stop every 30 minutes and drink a bottled water. Like I said above, most of us ain’t spring chickens, and you might be wondering if this means you’re going to be stopping a lot to pee. Hey, it’s a common old guy problem, but it won’t be in hot weather. Drink a lot of water; you’ll lose it through perspiration as you ride.

Seven: Avoid alcoholic beverages. Alcohol will cause you to dehydrate more rapidly, and that’s the opposite of what we’re trying to do here. You shouldn’t be consuming alcohol on a motorcycle ride anyway. Drinking any kind of alcohol while riding in hot weather is just stupid. Where I found you really have to watch this is when riding in a large group (there will be one or two riders who have to have that beer or two at lunch).

Eight: Stop regularly to cool off. Find a bit of shade or someplace air conditioned, and get off the bike to cool down. When I ride in hot weather, I usually stop to cool off and rehydrate every 30 minutes or so.

Nine: Keep your tires at recommended pressures. Another thing you definitely don’t want on a hot day is underinflated tires. Tires flex with every rotation, and flexing causes the tires to heat. Throw in high road surface temperatures with underinflated tires, and you’re flirting with a blowout. This is especially important to remember if you’re one of those guys or gals who deflate their tires for dirt riding. Don’t forget to pump them back up when you get back on the asphalt.

Ten: Don’t speed. Tar melts on hot days, and melted tar is slick. Factor that into your riding when it gets toasty.

Eleven: Eat light. Don’t over indulge. Heavy meals put a strain on your digestive system and your heart, and that can elevate your body temperature. When I was involved in testing munitions out in the Mojave on hot days (where it was sometimes over 120 degrees), we always brought along melons for lunch and nothing else. We didn’t need to keep them cool. They were a great treat, they seemed to make it a little cooler on those horrifically hot days, and they help to keep you hydrated. Good buddy Sergeant Zuo seemed to know all about that in China, too. We were riding through Ledu in central China one ferociously hot day when our favorite Chinese NCO stopped the group, disappeared, and returned with a couple of watermelons. That was a welcome respite and a marvelous treat. We ate a lot of watermelon in China.

Twelve: Lighten up on the low sodium schtick. A lot of us older guys try to watch our sodium intake. When I was in the Army, they actually gave us salt tabs on really hot days when we were in the field, the theory being that we needed the sodium because we were losing so much through perspiration. I later heard the Army reversed that practice, but the fact is you lose a lot of minerals through perspiration. I don’t worry about my sodium intake when riding on hot days.

So there you have it. You know, most folks who ride motorcycles these days…well, how can I say this delicately? We aren’t spring chickens anymore. Motorcycling tends to be a thing mostly enjoyed by full-figured senior citizens, and we have to take care of ourselves, especially when we venture out on hot days.

If you other ideas about hot weather riding, let us know in the Comments section. We love hearing from you.